It's been six years since Jaguar->ke39 and Land Rover->ke46 left the Ford->ke31 ownership umbrella, but the British automakers are still using Ford-derived engines they inherited back in the late 1990s. That's about to change though, as the Brits are set to introduce a new family of efficient powerplants. Dubbed Ingenium, these new engines promise to deliver a compelling combination of power, efficiency, and low CO2 emissions in many shapes and sizes.

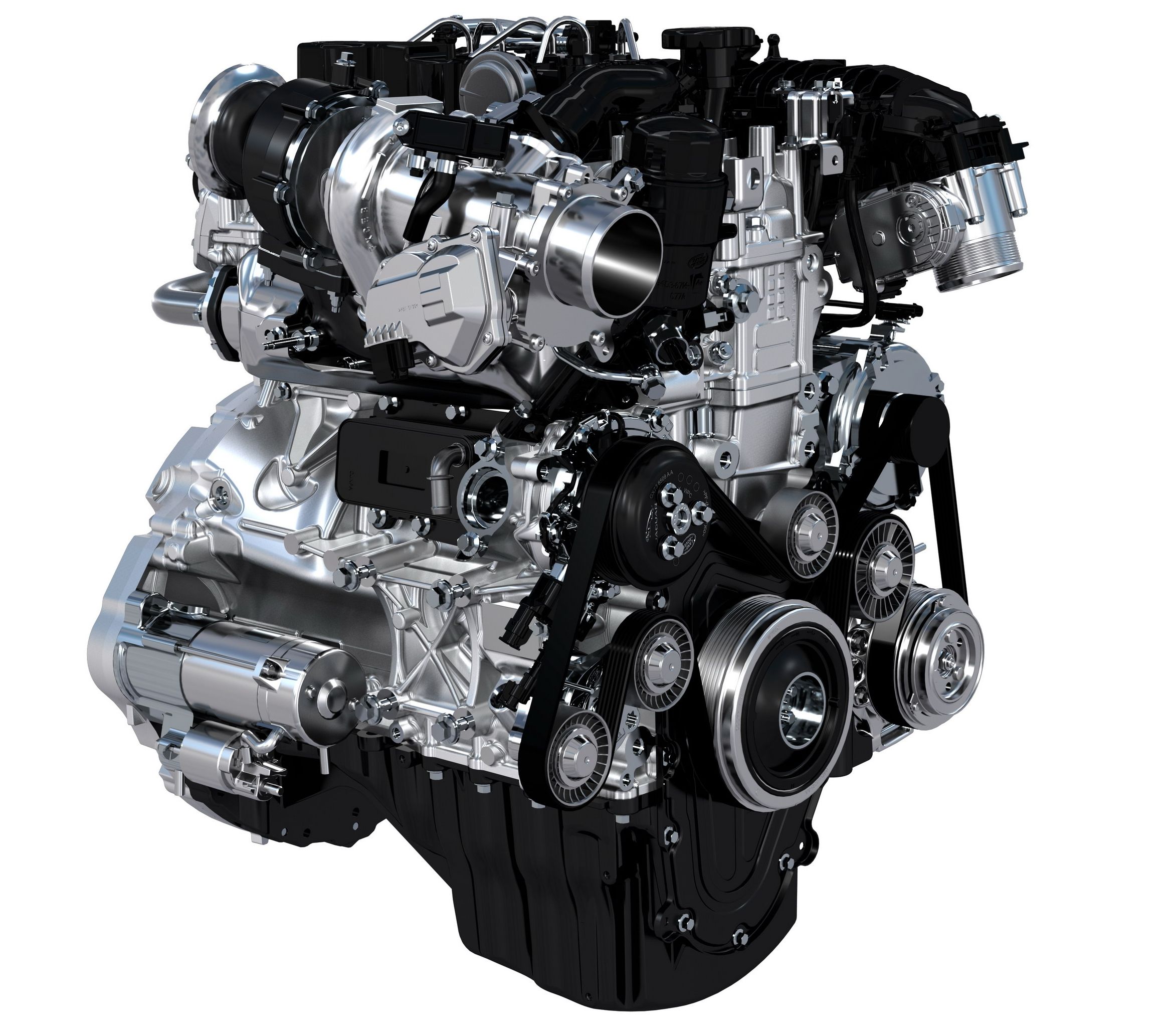

Built in-house at the company's new engine facility in Wolverhampton, England, the first version of the modular unit family is set to debut in the upcoming Jaguar XE and find its way into the Land Rover Discovery a few months after that. The Ingenium family will include both gasoline and diesel variants with turbochargers attached to them. As with all modular engines, JLR's new powerplants will share many internals and calibration strategies, enabling the company to raise quality and simplify manufacturing.

Looks like Jaguar Land Rover is finally growing up!

Click past the jump to read more about Jaguar's new Ingenium Engine Family.

Jaguar Ingenium Engine Family

Jaguar Land Rover's new engine family is based around a modular 500-cc-per-cylinder game plan. Specifically, all blocks will share the same bore, stroke, cylinder spacing and 500-cc cylinder capacity, a strategy similar to those used by BMW->ke178 and Mercedes-Benz->ke187. Although most details are still under wraps, JLR promises these engines will emit less than 100 g of CO2 per km in the 2016 Jaguar XE and weigh less than their Ford-based predecessors.

The first unit to roll out under the Ingenium banner will be a 2.0-liter turbo-diesel, Jaguar revealed, which will find its way into the upcoming 2016 XE sedan. The oil burner will be around 176 pounds lighter than the company's current four-banger and will reduce friction by 17 percent compared to the 2.2-liter diesel currently available. Naturally, it will hit engine bays with two different power outputs. A single-turbocharged version will sit at the bottom of the XE lineup, while a twin-turbo variant will deliver more horsepower to those in need of a sportier diesel. Output figures are still a mystery, but expect the diesel XE to rival the BMW 328d's 180 horsepower and 280 pound-feet of torque in its base configuration.

Although JLR has yet to elaborate as to what engines will join the 2.0-liter turbo-diesel in the Ingenium lineup, we figure the family will extend downward and upward with a 1.5-liter, three-cylinder and a 3.0-liter, inline-six or V-6 mill. The former could represent the basis of a future hybrid powertrain spread across the Jaguar and Land Rover lineup.

Why It Matters

It's about time Jaguar Land Rover ditched its ancient ties with Ford and develop a lineup of small-displacement engines of its own. The move comes just in time as Jaguar plans to take on the BMW 3 Series->ke290, Audi A4->ke1087 and Mercedes-Benz C-Class->ke1593 with the XE, and marks the beginning of a new era for JLR. Both Jaguar and Land Rover can look toward a more efficient and cleaner future, which will also make an impact on the company's lineup of high-performance vehicles. A lower carbon footprint will likely keep the supercharged, 5.0-liter V-8, and the awesome cars and SUVs->ke145 that come with it in production for a few more years. At the same time, adopting technologies such as twin-turbocharging will enable Jaguar to reduce displacement without upsetting performance-hungry customers and enthusiasts.

2016 Jaguar XE

Confirmed for the 2015 model year in Europe with a 2016 launch for North America, the Jaguar XE will arrive in showrooms as a BMW 3 Series fighter. The four-door compact will be underpinned by the company's all-new aluminum architecture -- previewed with the C-X17 Concept SUV -- and hit the streets with a bevy of engines under its hood. Diesel and gasoline units from the Ingenium lineup will comprise most of the lineup, with an F-Type->ke1224-sourced, supercharged V-6 to sit at the top of the range.

Design-wise, we expect the XE to keep most of Jaguar's traditional styling cues, but carry a few signature lines of its own. An aggressive front end, an arched trunk lid and a sloping roof are the main characteristics the XE will throw at the BMW 3 Series and the other German compacts->ke140 dominating the segment.