Despite the fancy title that Ferrari tagged it with - the Vettura Laboratorio HY-KERS- the long-awaited Ferrari 599 Fiorano Hybrid officially made its debut at the Geneva Motor Show today.

The HY-KERS system, which is a revolutionary new system Ferrari is developing that is capable of reducing CO2 emissions by up to 35% on the combined cycle (ECE + EUDC). Given the nature of this new eco-friendly technology, Ferrari is not ruling out the possibility that all future Ferraris - 8- and 12-cylinders, alike - will one day be fitted with the HY-KERS system.

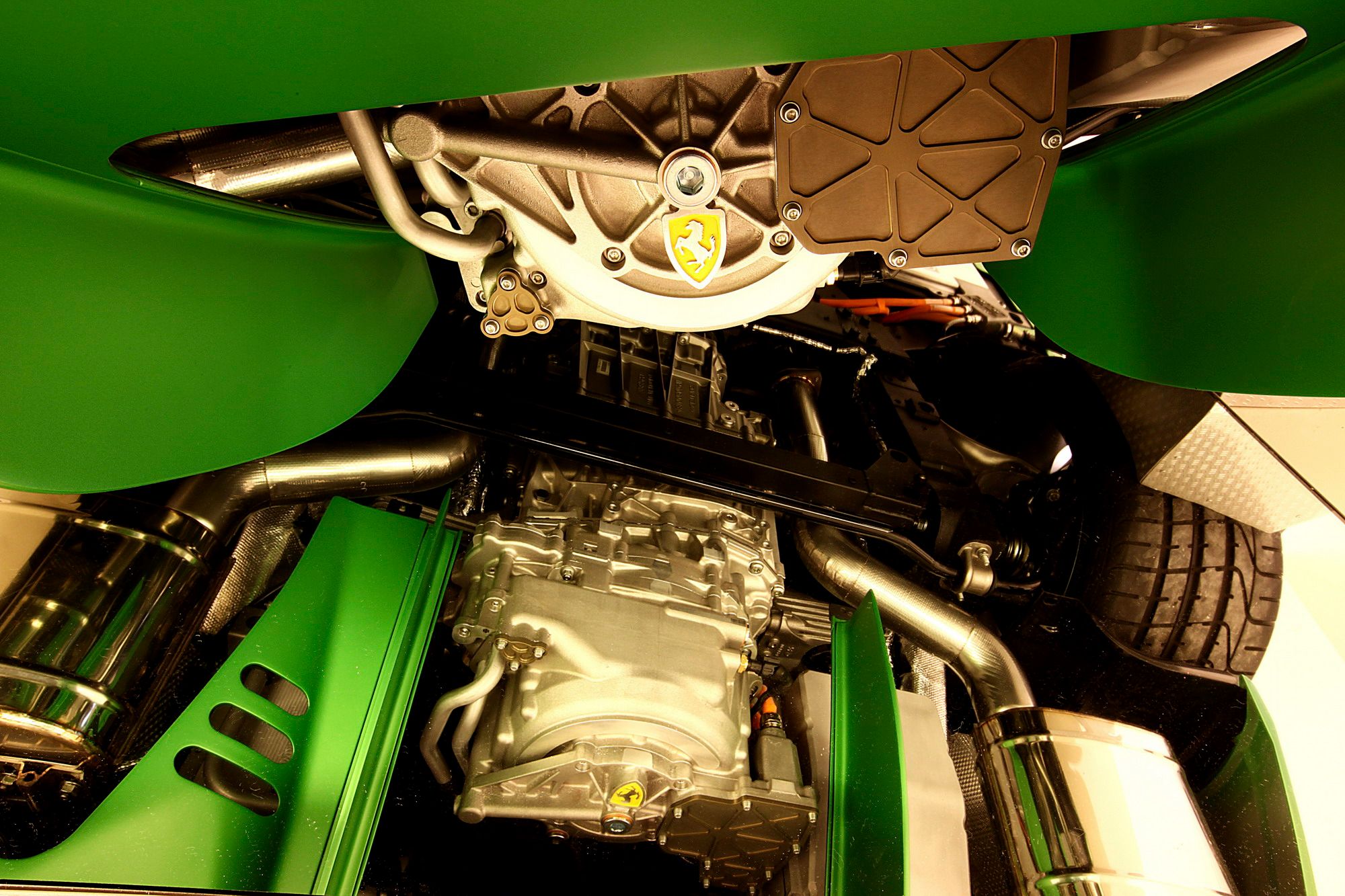

Through years of experience gained in Formula 1 - coupled with on-going research done round the clock in Maranello - Ferrari was able to apply a new and advanced, lightweight hybrid drivetrain to the 599 GTB Fiorano: a new kind of electric motor that helps optimize the longitudinal and lateral dynamics of the car, enhancing traction and brake balance. The motor also features a unique cooling and lubrication system for maximum efficiency under all operating temperatures and loads.

The high-voltage electric motor of the HY-KERS weights only 40 kilos and is coupled to the rear of the dual-clutch 7-speed F1 transmission. It operates through one of the transmission’s two clutches and engages one of the two gearbox primary shafts. Thus, power is coupled seamlessly and instantaneously between the electric motor and the V12. The electric motor produces more than 100 horsepower as Ferrari’s goal was to offset every kilogram increase in weight by a gain of at least one hp.

The whole project comes as a response to the likelihood that cars of the future will be subjected to a CO2 emission standards. Rather than stand pat and wait until the last minute to create a car that would be up-to-par with the rest, Ferrari is now in a position to meet and comply with those standards, especially when it comes to urban cycle where city driving is traditionally where sports cars are at a tremendous disadvantage because their engines are designed for maximum efficiency and performance at high revs, whereas the urban cycle involves low revs and low engine loads.

With this new technology, Ferrari has set themselves up nicely to meet future standards for all vehicles across the map while still keeping true to the brands tradition of creating high-end performance vehicles.

Press release after the jump.

2010 Ferrari Vettura Laboratorio HY-KERS

- Make: Array

- Model: 2010 Ferrari Vettura Laboratorio HY-KERS

- [do not use] Vehicle Model: Array

Press release

After the huge success enjoyed by the 458 Italia, a car that combines performance and sportiness with maximum efficiency to the extent that it boasts class-leading emissions and specific power output – 307 g/km of CO2 and 127hp/litre respectively - Ferrari is showcasing two major additions to its green credentials at the Geneva Motor Show. The first of these is the Stop & Start system sported by the Ferrari California, an industry first on a high-performance sports car, while the second is the HY-KERS, a “vettura laboratorio” (experimental vehicle) which reveals to the public for the first time the hybrid solutions being developed by Maranello’s engineers. Introduced with effect from March for the Ferrari California, the Stop & Start System cuts both fuel consumption and CO2 emissions by 6 per cent in the ECE + EUDC combined cycle, emitting around just 280 g/km, an excellent value for a high performance naturally-aspirated sports car. The Stop & Start cuts in virtually instantaneously - just 230 milliseconds, a time so fast that the driver barely notices the engine restarting.

Introduced with effect from March for the Ferrari California, the Stop & Start System cuts both fuel consumption and CO2 emissions by 6 per cent in the ECE + EUDC combined cycle, emitting around just 280 g/km, an excellent value for a high performance naturally-aspirated sports car. The Stop & Start cuts in virtually instantaneously - just 230 milliseconds, a time so fast that the driver barely notices the engine restarting.

This solution is a further step in Ferrari’s on-going strategy to reduce fuel consumption and emissions by working 360 degrees on all aspects of the cars. For example the Ferrari California’s direct-injection V8 boasts very low levels of friction. Purge valves in the crankcase counteract the differences in pressure below the pistons which normally increase losses. Other solutions also reduce friction, such as the DLC (Diamond Like Carbon) treatment of the valve followers and the highly polished cam lobes, an innovation that has now been adopted across the range.

The other new arrival from Ferrari at the Swiss show is more future-focused and gives the public its first glimpse of the HY-KERS vettura laboratorio which can reduce CO2 emissions by 35 per cent on the combined cycle (ECE + EUDC). The HY-KERS is based on the 599 GTB Fiorano but importantly, the technology may one day be fitted to all future Ferraris, 8- and 12-cylinders alike, regardless of their engine position. Thanks to ongoing research combined with experience gained in Formula 1, the new technology developed at Maranello actually accentuates the cars’ sporty character and driving involvement. One of the principle objectives of the project is ensuring that Ferrari will be in a position to comply with future CO2 emissions standards, particularly in terms of the urban cycle. City driving is traditionally where sports cars are most penalised as their engines are designed for maximum efficiency and performance at high revs, whereas the urban cycle involves low revs and low engine loads.

One of the principle objectives of the project is ensuring that Ferrari will be in a position to comply with future CO2 emissions standards, particularly in terms of the urban cycle. City driving is traditionally where sports cars are most penalised as their engines are designed for maximum efficiency and performance at high revs, whereas the urban cycle involves low revs and low engine loads.

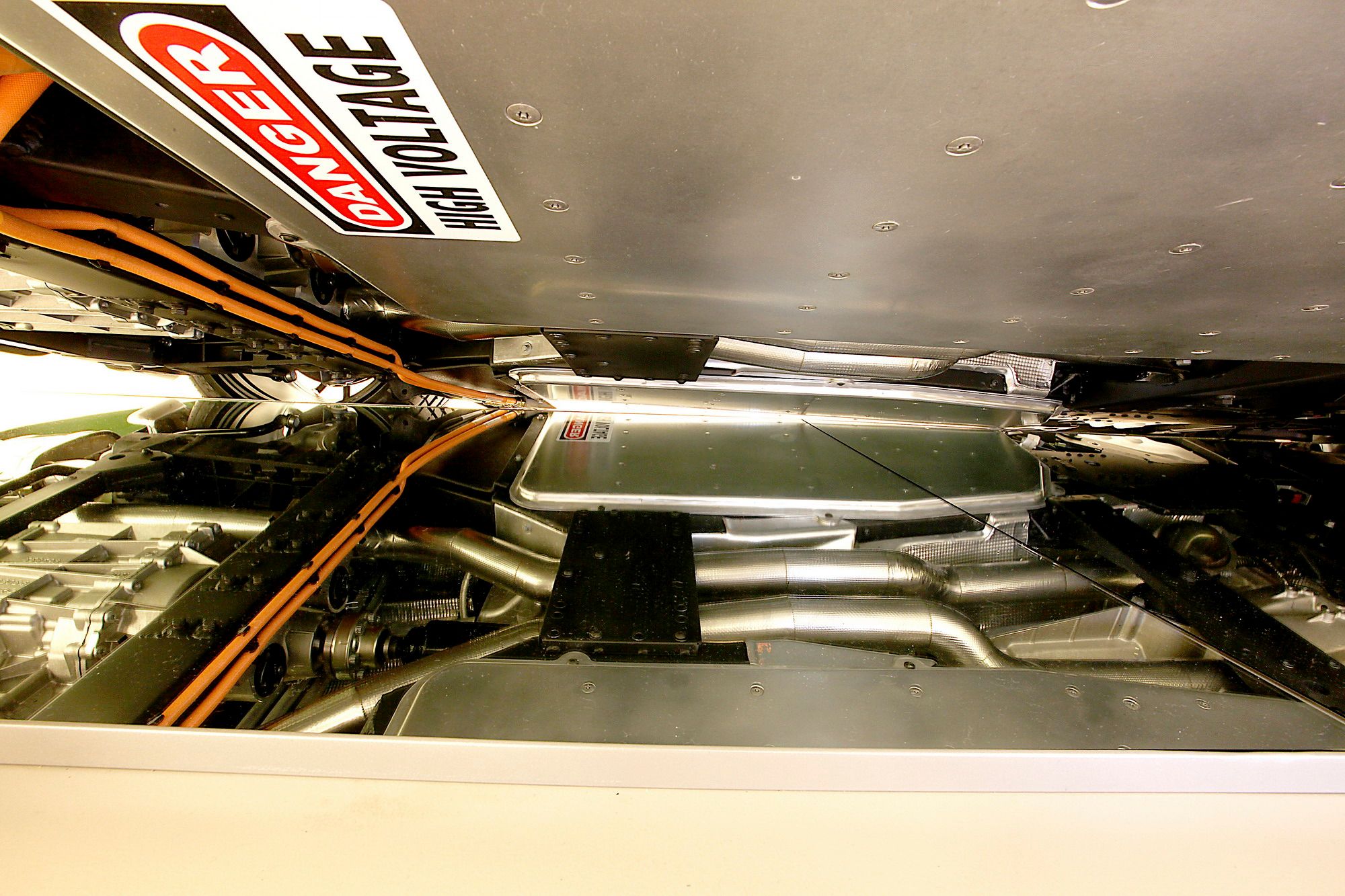

There are many original aspects to the new Ferrari hybrid transmission, starting with its architecture. Firstly, weight distribution has not been altered. This is thanks to positioning the batteries below the floorpan of the car, and the use of a compact electric motor coupled to the rear of the F1 dual-clutch gearbox. Not only does this layout not affect dynamic performance, it actually improves it, by lowering the centre of gravity. Cockpit room and luggage space are also unaffected.

Maranello’s engineers also employed Ferrari’s track experience in the design, engineering and manufacture of this innovative electric motor which produces over 100 hp. The algorithms and control logics controlling the torque, traction and braking distribution functions are directly derived from Formula 1. The solution adopted for the HY-KERS represents just one of the possible technologies for the future, but in the meantime Ferrari continues to evolve its models and increase their overall efficiency. Thus research continues into reducing drag, improving rolling resistance of tyres and lowering weight as well as working on reducing engine friction to increase efficiency.

The solution adopted for the HY-KERS represents just one of the possible technologies for the future, but in the meantime Ferrari continues to evolve its models and increase their overall efficiency. Thus research continues into reducing drag, improving rolling resistance of tyres and lowering weight as well as working on reducing engine friction to increase efficiency.

Ferrari’s research into reducing energy consumption has not been focused merely on its cars but also extends to the various production methods employed throughout the Maranello factory where the entire manufacturing process is carried out, from the foundry to the final assembly. In the course of 2010, Ferrari will cut CO2 emissions by 30,000 tons (-40 per cent) and Particulate Matter (PM) levels by 65 per cent. This will be achieved thanks to the company’s photovoltaic system and Italy’s largest trigeneration plant (which produces electricity, hot and cold water), making Ferrari entirely self-sufficient from an energy point of view. This reduction also means that Ferrari will meet the Kyoto protocol objectives a full 10 years ahead of schedule and with double the figure imposed on Europe.