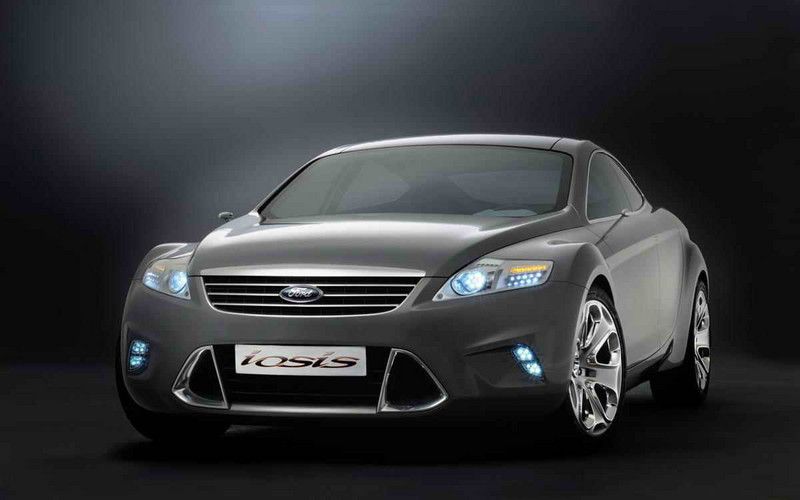

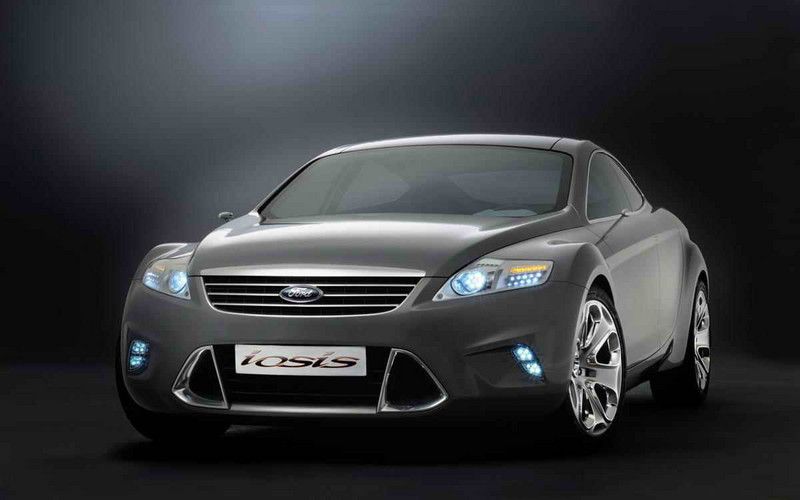

" Iosis is more than just a show car, it is sending a message about how Ford of Europe's future design will be redefined, says Martin Smith, Ford of Europe's Executive Design Director. "It sends a bold message because that is the way we are going."

2007 Ford Iosis

- Make: Array

- Model: 2007 Ford Iosis

- Horsepower: 0@0

Every car company has identifiable generations of vehicles and Martin Smith has been tasked with developing the next generation of vehicles for Ford of Europe. When he arrived at Ford last year, Smith recognised that Ford's leadership in driving quality needed to be reflected in the product's emotional and visual appeal.

"There is gathering evidence from the reception for the SAV Concept that we are heading in the right direction," said Smith.

He continued: Ford of Europe is acknowledged as being a leader in dynamics and amongst the best for craftsmanship as well as being affordable and reliable, now we are targeting design. Ford Iosis sends the message that Ford is driving for design leadership ."

What we're doing is visualising the dynamic qualities of the Ford brand. We are defining this as Ford kinetic design and when you look at Iosis you can see that it visualises energy in motion. Kinetic design defines the DNA that will drive us towards design leadership.

The design process: a coming together of tradition and technology

It is heartening to see two young men, one English one Italian, with barely an understanding of each other's language, together fashioning a cardboard template for the Iosis ceiling light display.

In an age when the microchip dominates every aspect of our lives, here were two individuals who could communicate their ideas to each other with the swish of a felt tip pen and the snip of a pair of scissors.

Pinned up around the walls of the coachbuilder's studio in Turin, Italy, were hand renderings of what the iosis design team visualised for their show car. Occasionally, you would see a craftsman with an unfinished component in hand, welds still visible, wander over and check the work against a design sketch and then return to their bench and continue the painstaking task of hand finishing the part to perfection.

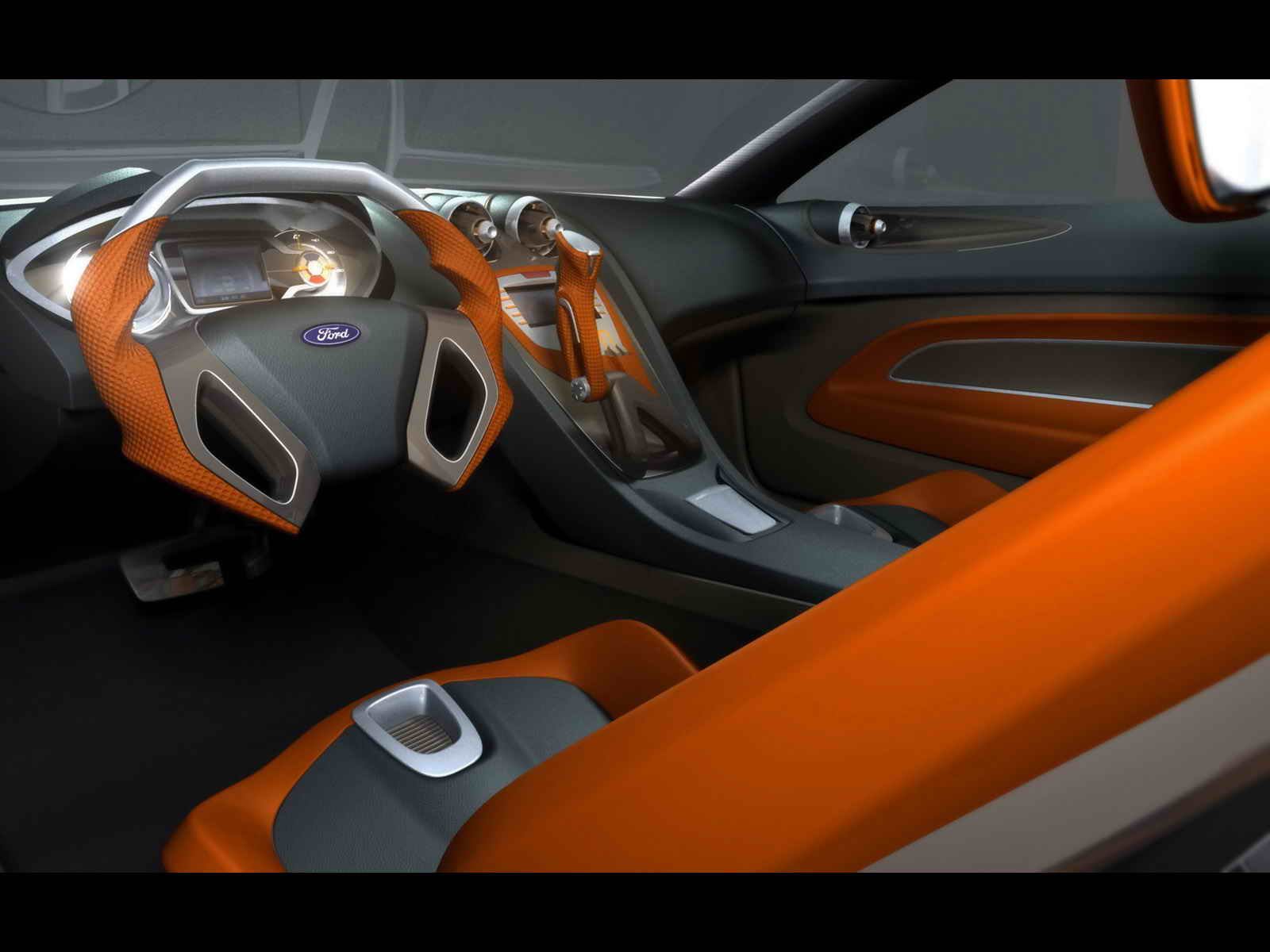

In another shop close by, the same dedicated skill is being applied to the interior trim and materials.

Ford produces cars by the thousand each day, the manufacturing process meticulously monitored by computers. But when it comes to concept vehicles, the design team reverts to skills and knowledge handed down through generations.

Stefan Lamm, Ford of Europe's Chief Designer for Exteriors said: "That's not to say we don't make use of Computer Aided Design or Computer Aided Engineering. We do, but in the right place at the right time."

Iosis started life as a series of free hand renderings by Ford of Europe exterior designer Andrea di Buduo, following briefings from Martin Smith. Working together with Domenico Tonello and Stefan Lamm, the team quickly refined the design to express Ford of Europe's new design DNA.

Simultaneously, a design team under Nikolaus Vidakovic comprised of Ernst Reim and Tony Peat were developing a similar theme for the interior. Meanwhile the Colour and Trim team led by Ruth Pauli, and including Silke Welskopp and Laura Blossfeld, produced a colour and materials concept .

Once the themes had been set, the design was honed using computer aided imaging to then present a proposal to senior Ford of Europe management.

The final computer imaging of Iosis was the tool used to move into the next stage of 3D model development. Once the Photoshop image has been finessed and a finished design agreed, it was subjected to software called Alias that roughly maps the surface so that a basic clay model can be machined.

Over the following six weeks, modellers carefully and painstakingly carved the clay into the final shape.

"This process," says Smith "is probably the most important during the gestation of a car's design."

Highly skilled Ford modellers are able to create this complex form. Computer-driven modelling is important but machines don't have the human touch, the experience and skill to appreciate the subtle nuances in design. The optimum and most efficient work stream is a combination of computer modelling and human skills.

After the clay is finished it is digitised using an automated process that measures the car's entire surface with pinpoint accuracy. That scanned data is then transmitted to the coachbuilder, in this case Modarte in Turin, who uses it to mill the master model. Even then, the process isn't finished and a further two or three weeks is devoted to honing each section by hand to perfection. After that moulds are produced from the master model and the body panels for the final bodyshell are created.

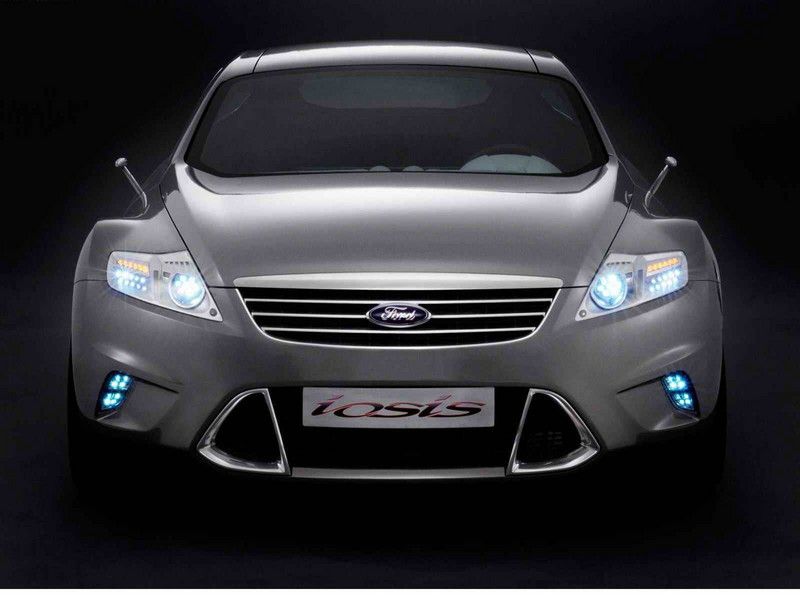

Details like the front and rear lamp assemblies, grille, exhausts and wheels, which are animated so the designers can see what they look like in 3D, are produced in Alias before mock ups are made to ensure they all neatly fit together. The technology of using 3D images full size on a video 'Powerwall' is often used to check the final design.

Then it's back to Modarte's workshop, a hive of frenetic activity as skilled machinists, metal workers, trimmers steadily work away at transforming iosis from a series of marker pen sketches to a stunning show car.

Exterior design development: a saloon that thinks it's a coupe

Unique proportions and a stunningly original design define Ford of Europe's new design language. An original double pivoting and pillarless door opening system for optimum interior access. Dramatic, precision, high technology lighting. Cameras replace rear view mirrors to offer unparalleled all-round visibility

"This car represents a vision of the future for Ford's design direction. It will send a very clear message that the SAV Concept was the first step forward in an exciting journey for Ford design. Iosis is the design statement that defines the future of the Ford brand in Europe.", Martin Smith, Ford of Europe's Executive Design Director