Update: The Spiritual Successor to the McLaren F1 - the Gordon Murrage T.50 - has launched with a similar three-seat configuration and ultra-lightweight, Cosworth-built engine, and the most impressive aerodynamic system of any supercar on the market today. Check out our full review of the Gordon Murray T.50 or all of our recent coverage of it}

The McLaren F1 was unveiled in May 1992 and was the company's first road-going production car. The idea was born in the late 1980s, when Gordon Murray, the technical director of McLaren's Formula One, began sketching the F1 as a three-seat supercar. Appointed as head of McLaren Cars in 1991, Murray convinced Ron Dennis to build the vehicle and played a key role in the design of the F1. It was unlike any other supercar launched up to that point. It had a race-inspired design, a three-seat configuration with the driver seat in the middle, and a comfortable ride for a vehicle of its kind. It was also the first production car to use a carbon-fiber monocoque chassis and the first to bring high-tech and expensive materials such as titanium, magnesium, Kevlar, and gold under the same roof.

Not only powerful and quick, the F1 was also the world's fastest production car. Its record endured from 1992 until 2005, when Bugatti unleashed the ludicrous Veyron. The F1 spawned a couple of special-edition models such as the LM and the GT, but it was also used as a base for the GTR race car. Essentially a standard F1 with aerodynamic improvements, the GTR went on to win the 24 Hours of Le Mans in its first year on the race track.

Some 25 years have passed since its introduction and the F1 is already considered a classic. Usually changing owners for millions of dollars, the F1 is one of the very few multi-million-dollar supercars built in the 1990s.

1993 McLaren F1

- Make: Array

- Model: 1993 McLaren F1

- Horsepower: 627@7400

- Torque: 5600

- [do not use] Vehicle Model: Array

Exterior

Inspired by prototype race cars, the styling of the F1 was somewhat in line with early 1990s supercars: it had a short front hood, a canopy-like roof, large doors, and a long rear deck. However, while similar vehicles from Lamborghini, Ferrari, and Bugatti were still using wedge-type cues reminiscent of the 1980s, the F1 had a more rounded design similar to the Le Mans prototypes of the era.

The headlamps were placed high on the front fenders and the turn signals and daytime running lights flanked the nose. Underneath, there were two large intakes that fed air to the front brakes.

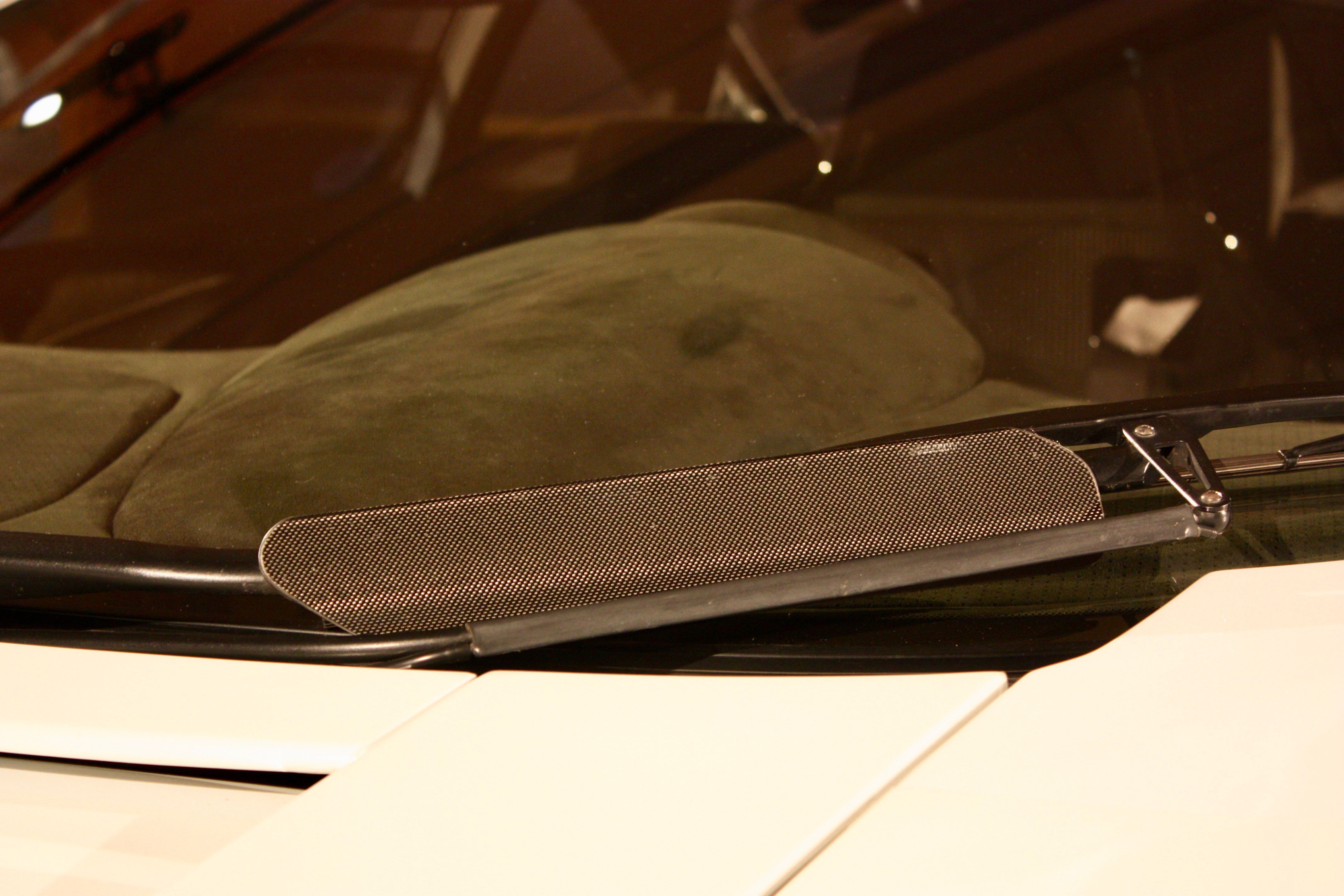

The F1 looked even more spectacular from the side. The gullwing doors, the opening side panels, and the swoopy waistline made the supercar look like a Transformers vehicle, while the lack of a rear wing gave it a clean, classy profile.

The rear fascia was pretty old-school, with big round taillights, a massive grille between them, and eight smaller mesh intakes underneath. The diffuser was rather subtle, while the quad-pipe exhaust was mounted in the center. The roof's fin-like element and the long deck lid gave it a race-inspired, unique appearance. Design-wise, the F1 had a certain degree of elegance that other supercars from the era didn't offer.

Interior

Arguably the most mind-blowing feature of the F1 was its three-seat configuration. The driver's seat was placed in the middle, flanked by to passenger seats mounted a few inches toward the rear. This solution offered the driver a Formula One-like position and made the F1 the first supercar to seat three people instead of only two. This feature is basically impossible to use nowadays due to safety restrictions and likely a complicated airbag system and continues to keep the F1 unique in this regard.

Due to the seat arrangement, the dashboard had a symmetric design with the steering wheel and the instrument panel right in the middle. Naturally, the pedals were also place in the middle of the cockpit, leaving room for the passengers on the left and right. The driver's was flaked by two thin consoles which housed several controls. The gear shifter was placed on the right, while the handbrake lever was mounted on the left. Also, the driver's seat had a race-inspired design, whereas the the two additional seats had a simpler, yet still sporty configuration.

Because the F1 was also designed for comfort and to appeal to rich customers looking for a luxurious ride, the floor was covered in soft carpet, while most of the surfaces were wrapped in leather. Carbon-fiber and aluminum, was also used throughout the cockpit.

The F1 also had a full cabin air conditioning, a rarity on most sports cars in the early 1990s, SeKurit electric defrost/demist windscreen and side glass, electric windows, remote central locking system, and a Kenwood 10-disc CD stereo system. The latter was a lightweight unit specifically developed for the F1.

McLaren also offered tailored luggage bags specially designed to fit the vehicle's carpeted storage compartments in the rear fenders. Standard features also included a tailored golf bag and a special-edition TAG Heuer 6000 Chronometer wristwatch with its serial number scripted below the center stem.

Drivetrain

When Murray convinced Ron Dennis to build the F1, he insisted that the engine is naturally aspirated for increased reliability and driver control. Murray initially went to Honda for a V-12 powerplant derived from the Formula One unit that powered the then-dominating McLaren-Honda cars, but the Japanese refused his proposal. He later persuaded BMW Motorsport to build him a 6.1-liter V-12 based on the M70 engine found in the second-generation 7 Series and 8 Series.

Murray requested an engine that would tip the scales at around 550 pounds while generating 550 horsepower. The BMW M-designed powerplant turned out heavier at 586 pounds, but also significantly more powerful at 627 horsepower and 480 pound-feet of torque. These were tremendous figures for the early 1990s, but became even more spectacular next to the F1's curb weight of only 2,500 pounds.

The V-12 mated to a transverse, six-speed manual gearbox with an AP carbon triple-plate clutch and a Torsen limited-slip differential.

The massive output and the lower curb weight made the F1 the quickest supercars of its era. The sprint from 0 to 60 mph came in just 3.2 seconds, while charging to 100 mph took a scant 6.3 ticks. It also needed only 28 seconds to hit 200 mph from a standing start. Its top speed was even more impressive at 231 mph, but this was the result of an electronic limiter due to safety concerns. The F1 was actually capable of more and in 1992 set a new world record at 240.1 mph, smashing the previous benchmark by a whopping 28 mph. During a private test in 1998, the F1 hit 243 mph with Andy Wallace behind the wheel.

The supercar rides on a double wishbone suspension system that was benchmarked to that of the Jaguar XJR16, Porsche 928S and Honda NSX. The steering knuckles and the top wishbone/bell crank were specially manufactured in an aluminium alloy, while the wishbones were machined from a solid aluminium alloy with CNC machines.

The lightweight wheels came wrapped in specially designed tires created exclusively for the F1 by Goodyear and Michelin. Stopping power came from unassisted, vented, and cross-drilled brake discs and aluminum calipers made by Brembo. Gordon Murray initially wanted to utilize carbon-fiber brakes for the supercar, but found the technology not mature enough. Carbon-ceramic brakes were later used in the GTR race car.

Prices

The McLaren F1 was priced from $815,000 back in 1992 (around $1.4 million in 2016), which made it hugely more expensive than other supercars. But despite the steep sticker, McLaren had no issues selling the 71 road cars it built until 1998. It worth noting that 64 were regular F1s, while five were LM-spec models based on the GTR race car and two were GT versions based on the GTR "Longtail." McLaren also built 28 GTRs and seven prototypes for a total production run of 107 units.

Although the F1 isn't even three decades old as of 2016, it fetches large amounts of cash at auctions. In recent years, several models changed owners for more than $3 million. Several records were set in recent years, starting with a $8.5 million sale in 2013. In 2014, an example previously owned by former IndyCar champion Michael Andretti was privately traded for around $10.5 million. In 2015, Rowan Atkinson, also known as "Mr. Bean," wanted $12 million for his F1.

Competition

Bugatti EB110

The EB110 was introduced in 1991, one year ahead of the F1, as the first Bugatti model since 1962. Developed and sold by Bugatti Automobili, which was created by Romano Artioli who purchased the Bugatti brand, the EB110 was an ambitious project that didn't really catch on and drove the company into bankruptcy four years later. Despite this, Bugatti managed to build 139 units, including the beefed-up SS model and even a motorsport version. Powered by a quad-turbo, 3.5-liter V-12, the EB110 had 552 horsepower at its disposal and needed around 3.3 seconds to hit 60 mph toward a top speed of 213 mph. The SS was more powerful at 603 horsepower, but still lacked the F1's tremendous top speed, being capable of only 216 mph. Pricing began from around $350,000, significantly less than a F1.

Find out more about the Bugatti EB110 here.

Jaguar XJ220

The XJ220 was yet another ambitious project of the early 1990s. Launched in 1992 as a two-seater, luxury supercar, the XJ220 had a sleek, prototype-like design and a rich interior featuring the finest leathers available at the time. Unlike the F1 and EB110, the Jag came with a twin-turbo, 3.5-liter V-6, despite original plans to offer it with a race-spec, TWR-designed V-12. Similar to the powerplant in the MG Metro 6R4 rally car, the V-6 was good for 540 horsepower and 475 pound-feet of torque and enabled the XJ220 to accelerate from 0 to 60 mph in 3.6 seconds. Its top speed stood at 217 mph with the rev limiter, but Jaguar set a 223-mph record wihtout it just before McLaren launched the F1. The British firm produced 271 cars before production ended in 1994. The supercar retailed from £460,000.

Learn more about the Jaguar XJ220 here.

Conclusion

If I were to put together a Top 10 Supercars from the 1990s, the McLaren F1 would most definitely be No. 1. This supercar has everything it needs to be the best vehicle of its decade. It was powerful, it was fast, and had an unprecedented amount of pioneering technology in its construction. The F1 marked the beginning of new era for supercars, as most manufacturers used it as a benchmark for future products. The F1 made Ferraris seem outdated back in the day and held the record for the world's fastest production car for no fewer than 12 years. The fact that it spawned a successful race car that was only a mild update over the road car makes it that much better. All told, its current million-dollar sticker speaks volumes of the legend it created since day one!