There is no technical definition for what makes a car a supercar, and as such, there will always be some disagreement about what car should be considered the first to have reached this status. There is no shortage of possible contenders, but the biggest debate is between the Lamborghini Miura->ke378 and this, the Mercedes-Benz 300SL. ->ke1995

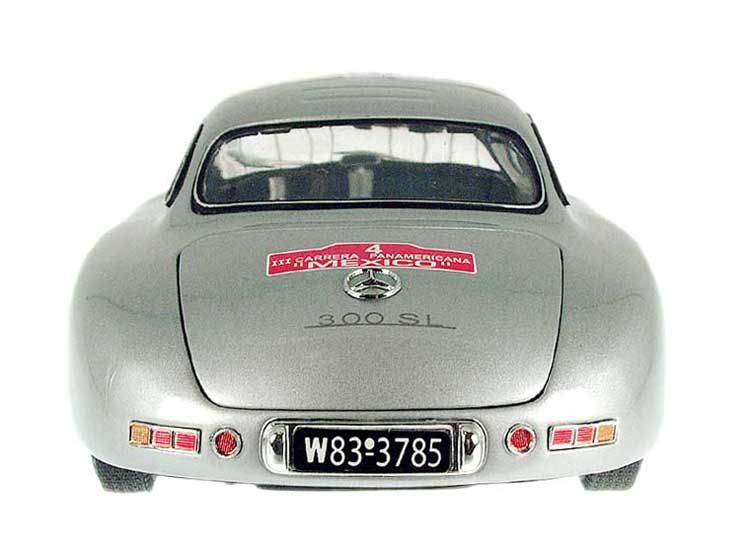

The 300SL was derived from a race car->ke148 by the same name, which is noteworthy because it is usually the other way around, with race cars being built out of existing road-going models. It's usually too difficult to go in the other direction, especially when you're talking about a car that had overall wins at Le Mans,->ke1591 the Nurburgring and the Carrera Panamericana. But, in the '50s, road cars and track cars weren't so divorced from one another that it was impossible.

The idea for a Grand Prix car that was repurposed for road use was pitched to Mercedes by the Austrian-born, but New York-based importer and car dealer Max Hoffman, who would also go on to suggest several successful cars to Porsche.->ke1 Because of this, the car debuted at the New York Auto Show,->ke226 a first for a Mercedes->ke187 product, and was instantly the hit of the show.

Continue reading to learn more about the Mercedes 300SL Gullwing.

1957 - 1962 Mercedes 300SL Gullwing (W194)

- Make: Array

- Model: 1957 - 1962 Mercedes 300SL Gullwing (W194)

- Horsepower: 215@5800

- Torque: 4600

- Transmission: 4-Speed Manual

Exterior

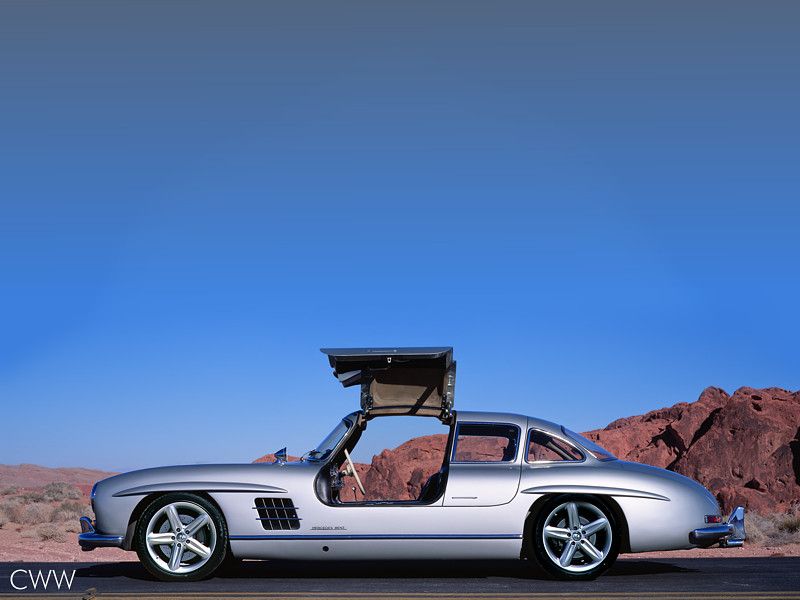

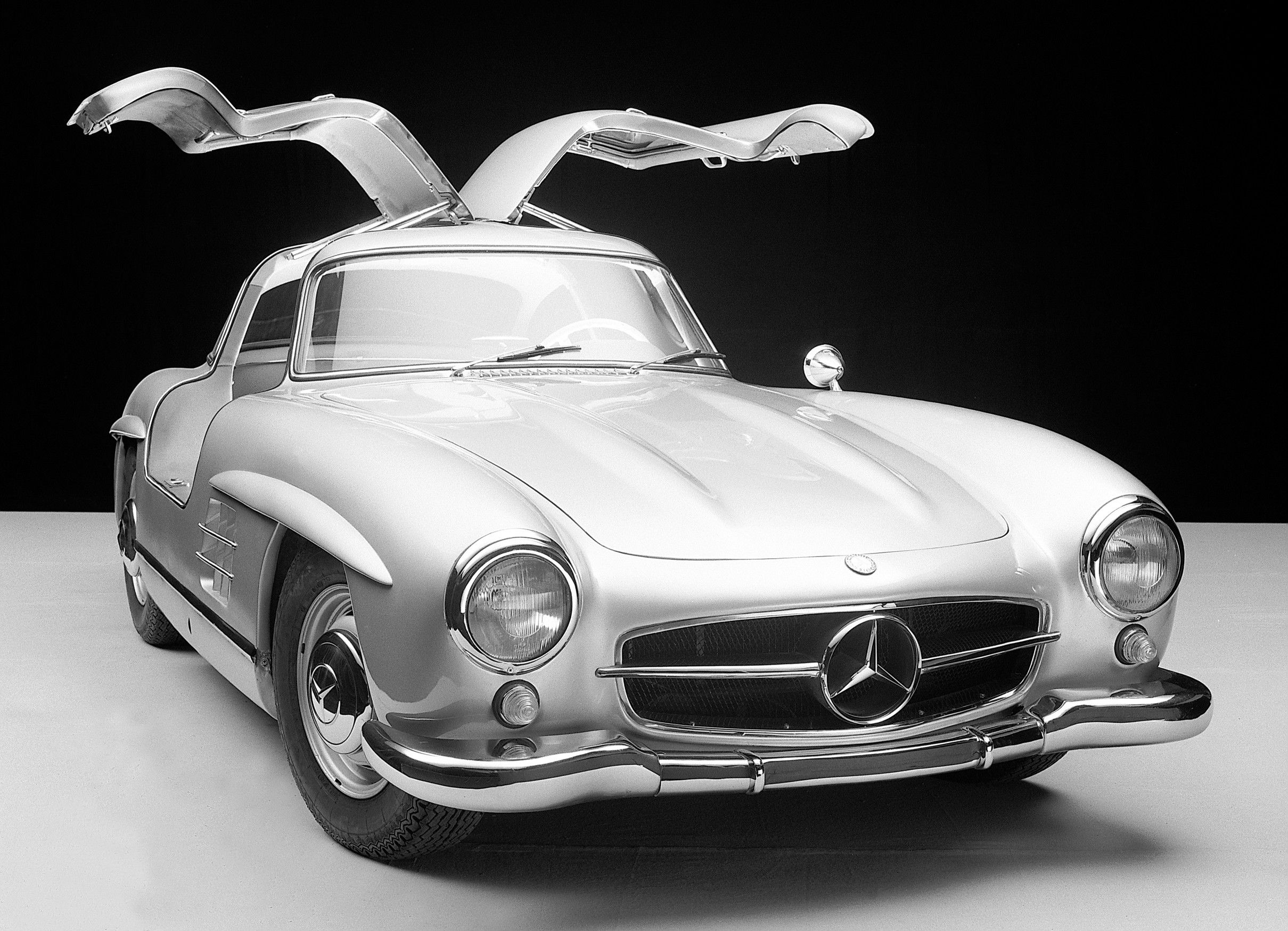

The general shape of the 300SL is actually remarkably similar to the race car that it is related to. This shouldn't seem like too big of a surprise, but it can be difficult to imagine a car that is so flashy and so sought after by the most fashionable of people could possibly have been based on something so utilitarian as a race car. Of course, some parts of the car are unique to the road version, most notably the iconic gullwing doors.

These are so much a part of the car's look that car is often referred to as just “Gullwing.” This is especially interesting because most 300SLs didn't have them. The roadster version of the car had to have conventional doors because there was obviously no roof to mount gullwing doors on. Roadsters made up more than half of all 300SL units, but it is almost always the hardtop that we think of in connection to the 300SL. It is a very sleek look for 1954, with an unusually low hood for the time.

The design holds up incredibly well, to the point that Mercedes sold the SLS AMG, a modernized version of what was essentially the same shape, some 55 years later.

Interior

The interior of the 300SL is a rolling textbook of '50s industrial design, all polished metal and chrome. The dash was often, but not always, painted to match the body color. A wide variety of color options were available for the interior, and while these were usually leather, a lot more of them than you would expect are in color matched plaid fabrics. Looking at the interior, you might notice two handles, one at either end of the dash. These were in as a workaround to the single biggest drawback of the car.

The gullwing doors meant the 300SL had enormous and very high sills, and getting over them while entering or exiting the vehicle, while still maintaining some sort of dignity, was an unusually difficult task. This was an especially big problem for the driver, and the tiltaway steering wheel only made things somewhat better. Given these problems, its probably best that the 300SL didn't have a back seat, as one can only imagine how difficult that would have been to use.

Drivetrain

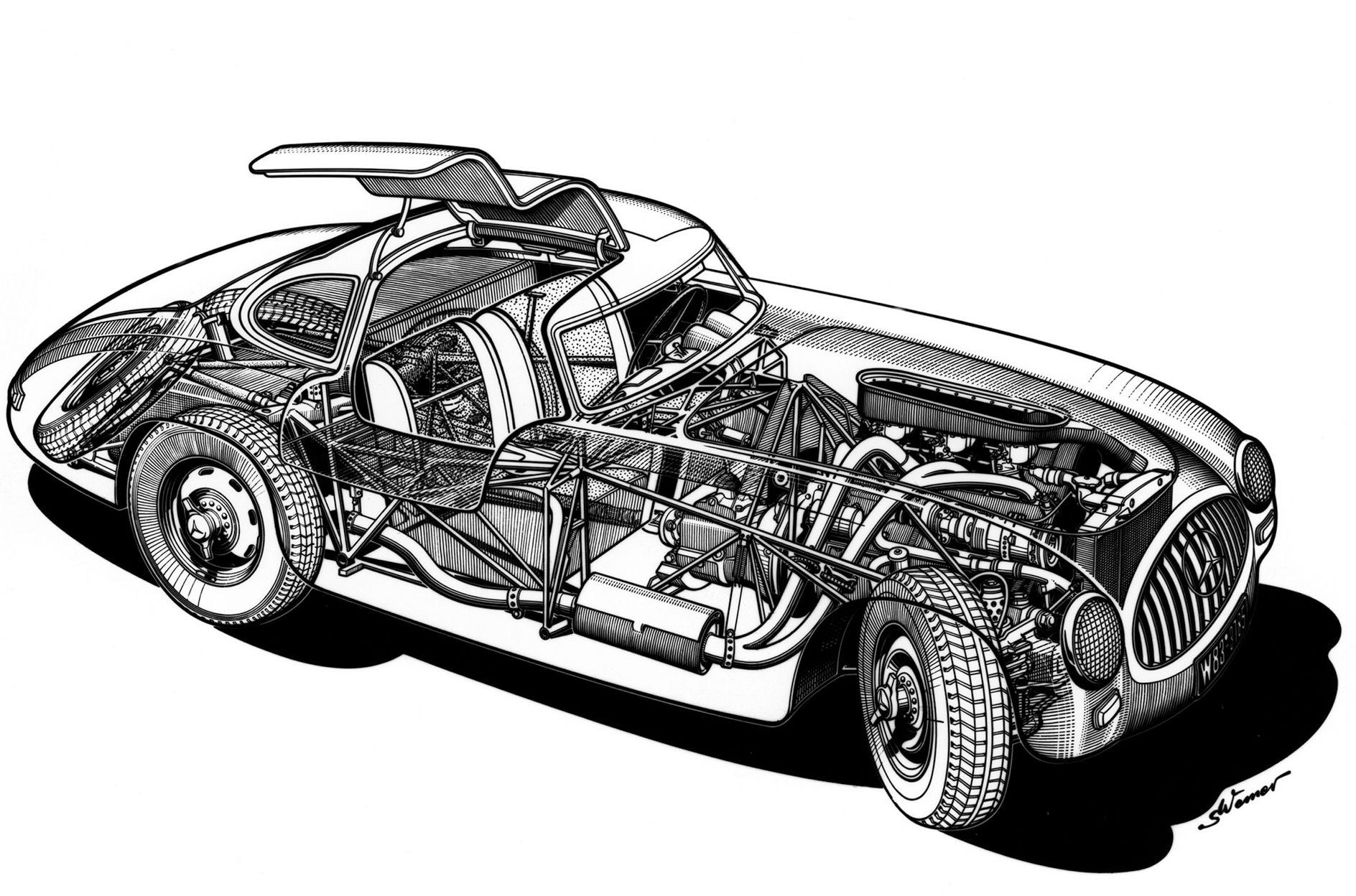

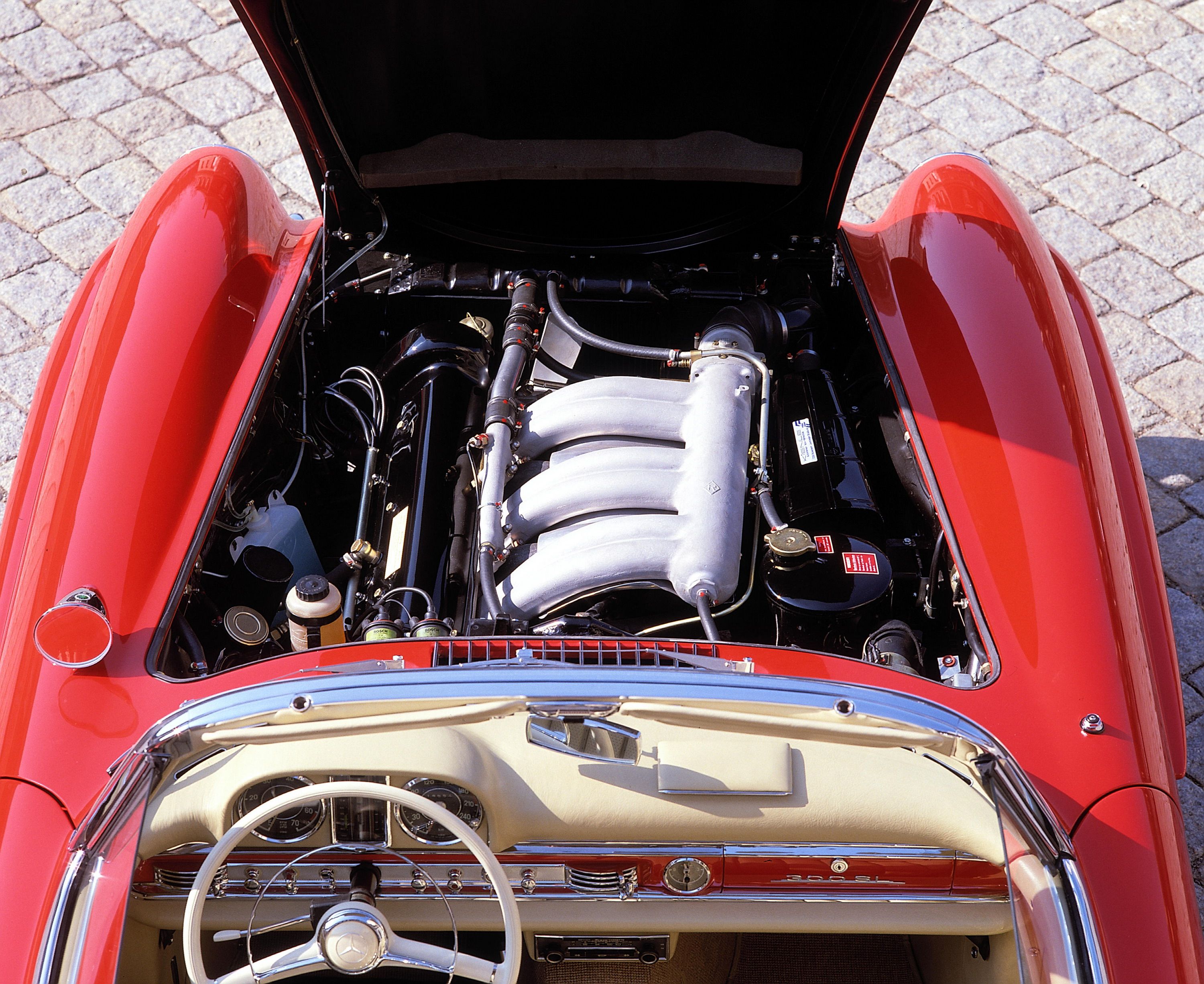

When making the 300SL racecar, Mercedes took the engine out of its big 300 series sedan and put it into a small and lightweight car, always a good tactic for going fast. But, when it came time to put the engine into the road car, the engineers really put some serious effort into making it better. The design of the roadgoing body had such a low hood that the inline-6 engine had to be canted 50 degrees in order to fit under it. The carburetors that had been used in the race car were replaced with a hugely sophisticated Bosch mechanical direct injection system.

This bumped the power up from the unimpressive 175 horsepower of the race car to 215 horsepower, a full 100 horsepower more than the first 300 got out of the same engine just three years earlier. The engine was not without its faults, such as a giant 10-liter oil capacity and large racing oil cooler contributing to a long wait for the oil to get up to temperature, with the engine being inadequately lubricated in the meantime.

But, people were generally willing to put up with these shortcomings because the extra power made the 300SL the fastest production car in the world at the time -- always an important thing when you're making the case for something to be a supercar.

Prices

The 300SL was clearly not a cheap car, this being something that could be said about today's supercars as well. But, the 300SL had the whole supercar market basically to itself, and Mercedes-Benz being a big automaker was able to keep up with demand. So in all, Mercedes built 1,400 gullwing coupes, along with a further 1,858 roadster versions of the car.

Those are pretty big supercar numbers, and it would be a long time before any other manufacturer would be able to sell supercars in those kinds of quantities. That's what makes the current prices for 300SLs so amazing. They tend to sell for between $1 million to $2.5 million, although a rare aluminum-bodied example went for $4.6 million a few years ago. Those are the kinds of prices usually commanded by cars with production runs one tenth the size of this one, and it says a lot about the 300SL that it can still cost so much despite its relative lack of rarity.

Competition

Jaguar XK140

Before the 300SL took the record of fastest production car, the title was held by the Jaguar XK120. That car evolved into the XK140, debuting the same year as the 300SL. Like the Mercedes, the XK140 was closely related to a race car. A race car that was, in fact, the rival to Mercedes on the track. Jaguar dominated Le Mans in the '50s, and those that bought the company's road cars got the benefit of that relentless drive to be the best. The XK140 might not have had a top speed as high as the 300SL, but Jaguar's racing record tell us that might not have been so important.

Aston Martin DB4

What could be a better competitor than the car that took away the 300SL's title of fastest production car? The DB4 might not be as famous as the Bond car that came after it, but the truth is that it was the DB4 that made Aston Martin the company it is before anyone was even thinking of mounting machine guns or ejector seats in them. Aston Martin sales shot up when the DB4 was introduced, and the company broke its own speed record when the DB4 GT debuted.

Read our full review here.

Conclusion

It would be an understatement to call the 300SL an icon. It wasn't just that it forever changed the image of Mercedes-Benz, especially in America, where more than half of the units were sold, an unheard of thing in the '50s. It also wasn't just that it bridged the gap between road cars and race cars in a way that few postwar cars have ever done. What was possibly the 300SL's biggest contribution to the automotive world was the idea of the supercar as a technological wonder. It didn't just look good, it wasn't just fast, it had tech under the hood that no other car had. That's real exclusivity, and all of the special editions and coachbuilt bodies in the world are no match for it.