Just as the values, goals, lifestyles and interests of people change, so their expectations of the automobile change accordingly. The experience factor is gaining in importance, but comfort, practicality, attractiveness and performance are also expected. These are attributes that present vehicle concepts can only offer in part.

mercedes-b-class

- Make: Array

- Model: mercedes-b-class

2005 Mercedes B-class

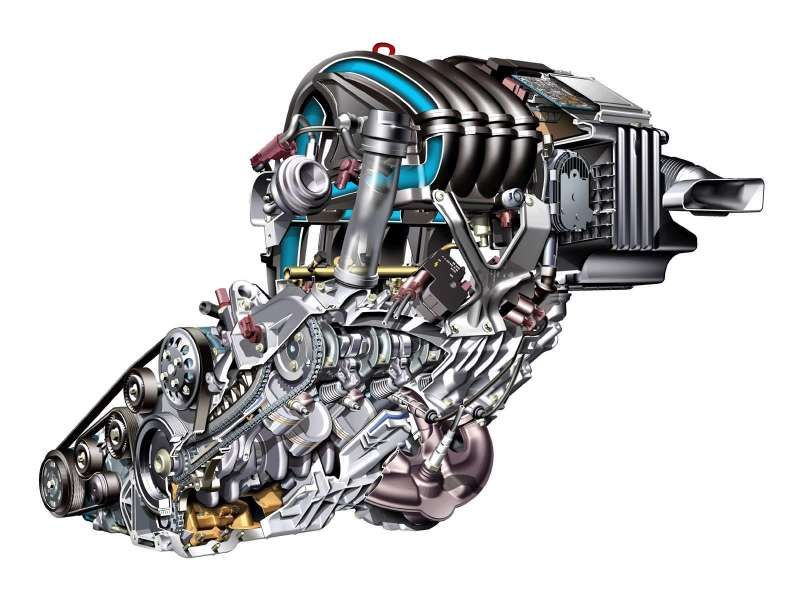

- Horsepower: 193@5000

- Torque: 280@1800–4850

- [do not use] Vehicle Model: Array

In other words, a young generation wants to be different - and drive differently. It is asking for a new form of car mobility, and for new formats.

The time is right: the world needs new car ideas.

Mercedes-Benz has the answer: the Sports Tourer concept.

- Acceleration skid control

- Active front head restraints

- Adaptive airbags for the driver and front passenger

- Air conditioned glove compartment

- Air conditioning with dust filter and air recirculation

- Anti-lock braking system

- Armrest and stowage compartment in the tunnel covering

- Belt force limiters in the front and on outer rear seats

- Belt tensioners in the front and on outer rear seats

- Brake Assist

- Central locking with remote control

- Chrome and brushed aluminium trim

- Cup holders at front and rear, also in the door panels

- Disc brakes all-round, front discs internally ventilated

- ESP

- Exterior mirrors heated and electrically adjustable

- Fog lamps and rear fog lamp

- Folding front passenger seat backrest

- Folding rear seat unit with 1/3 : 2/3 division, removable seat cushions

- Head/thorax sidebags in the front backrests

- Heated washer nozzles

- Height-adjustable load compartment floor

- Height-adjustable steering column

- ISOFIX child seat attachments

- Luggage compartment cover

- Multifunction steering wheel

- Outside temperature display

- Power front windows

- Projection-beam headlamps

- Rear seat belt status display

- Rear wiper with intermittent and convenience modes

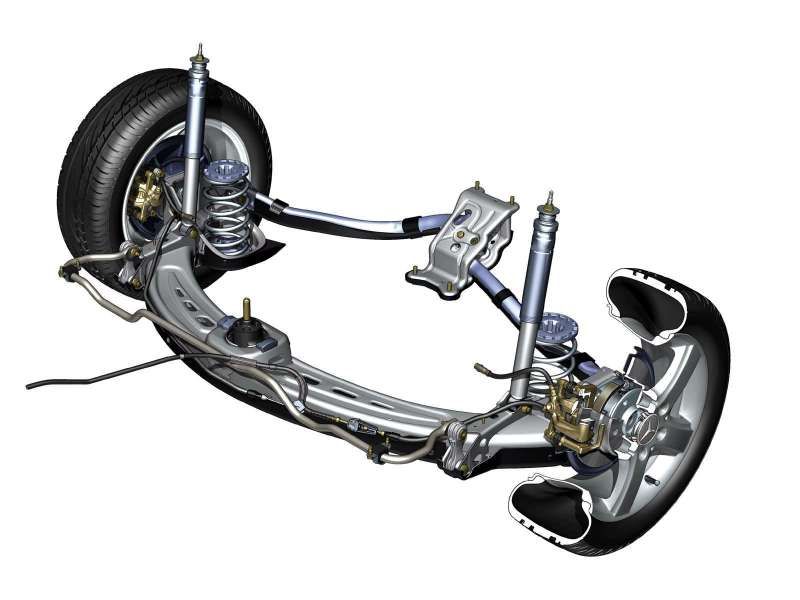

- Selective damping system

- Six-speed manual transmission (B 180 CDI, B 200 CDI, B 200 TURBO)

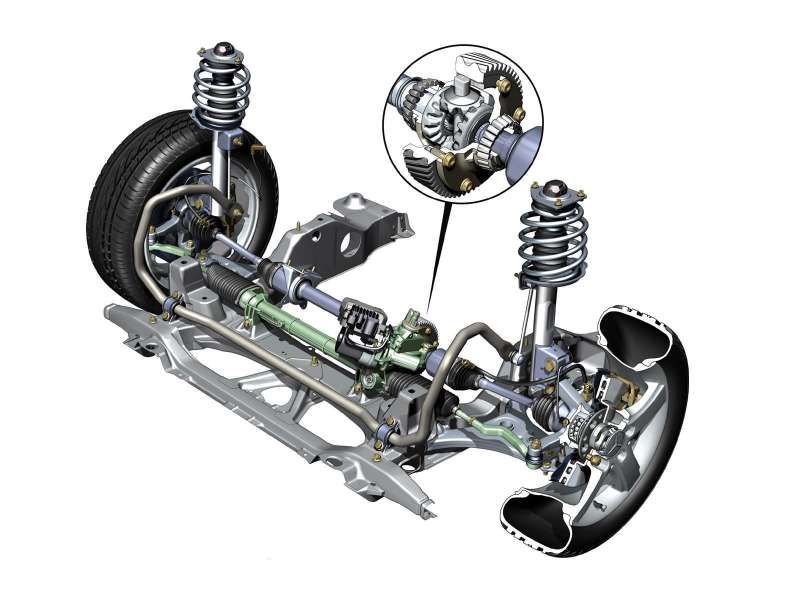

- Speed-sensitive power steering with parameter function

- STEER CONTROL steering aid

- Surround and signal lighting in the tailgate

- Tinted glass

- TIREFIT tyre repair kit

- Trip computer

- Tyre pressure loss warning

Optional extras: technology for the most demanding

High-tech systems from the Mercedes-Benz luxury class are available for the new B-Class as optional equipment. These make the compact Sports Tourer even more comfortable, more versatile - and unique. A selection from the range of optional extras:

- 16, 17 and 18-inch light-alloy wheels

- 6 CD changer

- Anti-theft alarm

- Audio 50 APS radio and navigation system

- Automatically dimming rear-view mirror

- AUTOTRONIC automatic transmission

- Bi-xenon headlamps with Active Light System, cornering lights and headlamp cleaning system

- Child seat recognition

- COMAND APS

- Diesel particulate filter

- EASY-VARIO system

- Front seats electrically adjustable

- Integral child seats in the rear

- Leather upholstery

- Multicontour driver’s seat

- Panoramic louvred sunroof

- Panoramic roof

- PARKTRONIC parking aid

- Rear armrest with cup holder and through-loading facility

- Rear sidebags

- Run-flat tyres

- Sound system with surround sound

- Sports seats for driver and front passenger

- Sports suspension

- Steering-wheel gearshift buttons (in conjunction with AUTOTRONIC)

- THERMOTRONIC automatic climate control

- Windowbags

To make it as easy as possible for customers to choose from the extensive range of attractive optional items, Mercedes-Benz has ensured the maximum scope for flexibility. When placing their order customers are already given a confirmed delivery date, however changes can still be made to the paint finish, upholstery or optional items up to six working days before this delivery date.

Packages: attractive offers for more individuality and practicality

In the new B-Class, Mercedes-Benz meets the wishes of today’s customers for more individuality with attractive equipment packages. These particularly enhance three attributes of the Compact Sports Tourer, namely its elegance, dynamism and practicality.

The exterior chrome package (optional) includes:

- Exterior mirrors in the vehicle colour

- Fog lamps with chrome surround

- Radiator with chrome strips

- Rub strips and door handles with chrome inserts

- Side skirts in vehicle colour

- Stainless steel exhaust tailpipe

- Waistline trim strip, loading sill and loading floor handle in chrome

- Windscreen with band filter

The optional sports package upgrades the B-Class with the following extras:

- 17-inch light-alloy wheels

- ARTICO man-made leather/ Maastricht fabric upholstery

- Exterior mirrors in the vehicle colour

- Fog lamps with chrome surround

- Instrument cluster with white illumination

- Leather-covered parking brake handle

- Oval exhaust tailpipe in stainless steel

- Pedals with stainless steel caps and rubber studs

- Radiator grille with chrome strips and three louvres

- Rear bumper of distinctive design with decor strips

- Rub strips and door handles with chrome inserts

- Shift lever leather-covered with aluminium cap

- Side skirts in the vehicle colour

- Sports suspension

- Steering wheel with two aluminium inserts and perforated leather

- Tinted rear lights

- Waistline trim strip, loading sill and loading floor handle in chrome

- Windscreen with band filter

In addition Mercedes-Benz has put together equipment packages which further improve lighting, visibility and comfort:

- Exterior lighting and visibility package:

- Bulb failure indicator

- Failsafe light function

- Headlamp Assist

- Headlamp switch-off delay

- Locator lighting

- Rain sensor for the windscreen wipers

- Windscreen with band filter

- Interior lighting package:

- Entry/exit and signal lights in the front doors

- Front footwell lights

- Reading lamp for the driver

- Reading lamps in the rear

- Sun visors with illuminated vanity mirrors