Mercedes-Benz will in future also market its SLR McLaren super sports car in the form of a roadster with a top. In common with Formula 1 vehicles of today, it, too, will be made of carbon fibre, a material that will endow the vehicle with a very high degree of safety as well as extreme torsional stiffness at the same high level as the coupé version. This gives rise, in combination with the racing-type chassis, to outstanding ride characteristics.

mercedes-benz-slr-mclaren-roadster

- Make: Array

- Model: mercedes-benz-slr-mclaren-roadster

2008 Mercedes-Benz SLR McLaren Roadster

- [do not use] Vehicle Model: Array

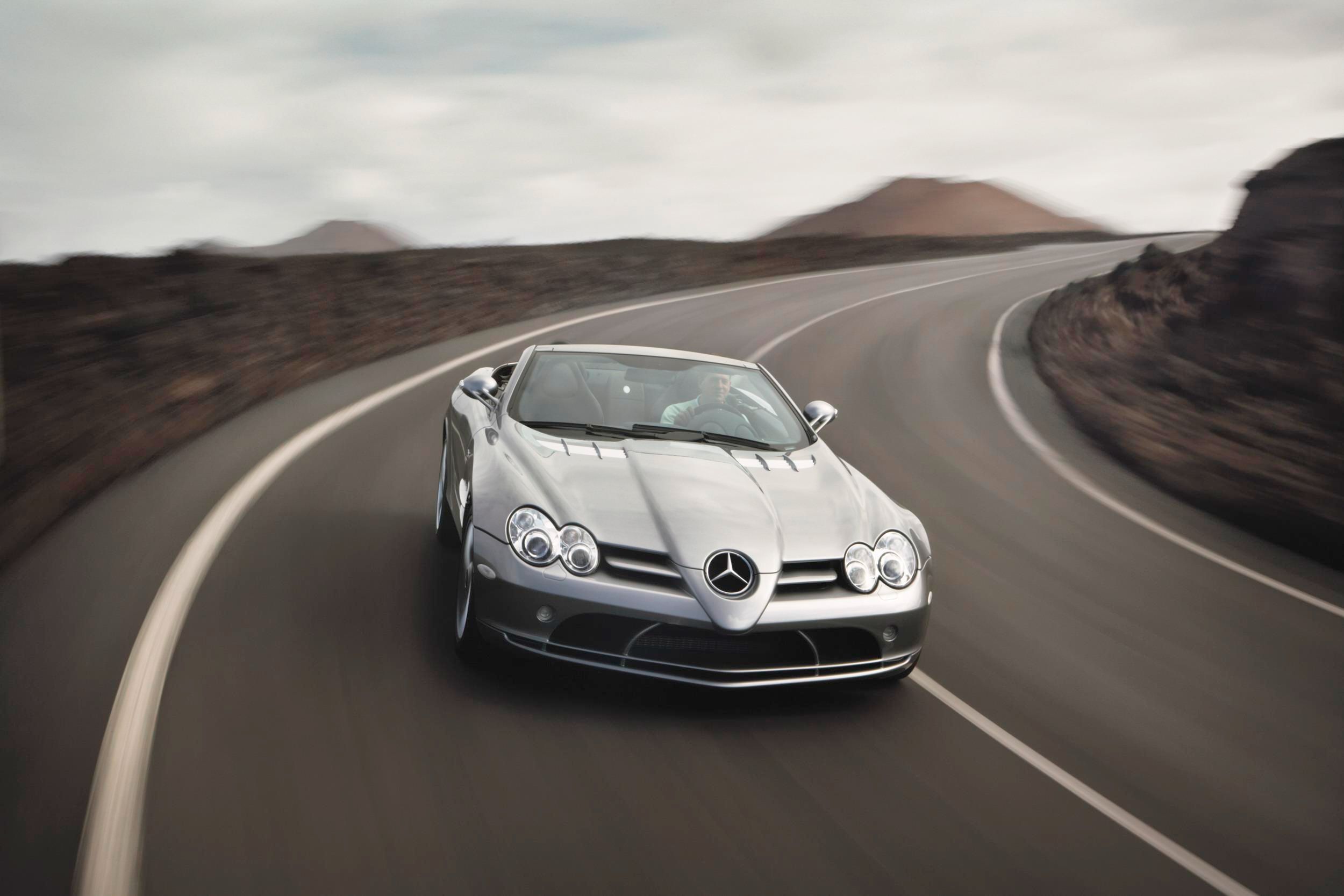

The maximum speed of the new high-performance sports car, which is powered by an AMG V8 compressor engine delivering 460 kW/626 hp, is 332 km/h, therefore at the same high level as the coupé. Although, thanks to its fully retractable top, the Roadster offers undiluted open-air driving pleasure in the highest performance class, its occupants in no way lose out in terms of comfort or the vehicle's suitability for everyday use. Consequently, the new Roadster opens up a new dimension in refinement for open-top super sports cars.

Like the coupé version, the new Mercedes-Benz SLR McLaren Roadster once again unites the legend of the successful SLR racing models from the 1950s with the innovative technology of modern Formula 1 vehicles from the Vodafone-McLaren-Mercedes team. Typical stylistic elements, such as the arrow-shaped tip of the Formula 1 Silver Arrow, establish a visual link with the racing cars. The SLR leg-end of the 50s lives on stylistically in the distinctive lateral louvers, side pipes behind the front wheels and the wide-opening gullwing doors.

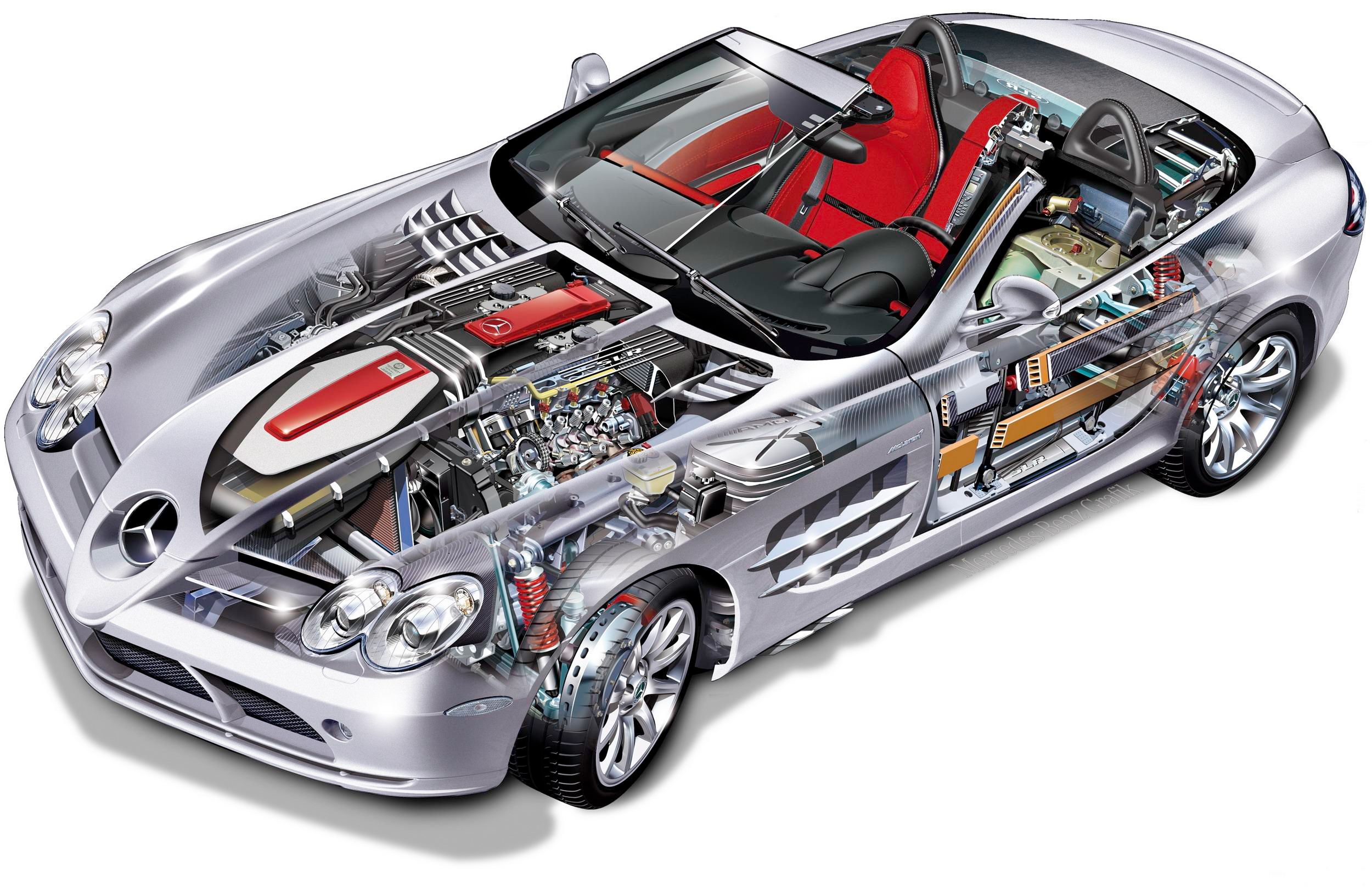

The new Roadster benefits technically from the many years of experience of Mercedes-Benz and its Formula 1 partner McLaren. Apart from two aluminium engine frames, its body is made entirely of carbon-fibre reinforced plastic (CFRP) materials, making the vehicle an exception among high-performance sports cars. Especially for the Roadster, complex carbon-fibre technology has been intelligently further developed for the monocoque chassis. The result is low weight, exemplary energy absorption and, therefore, extremely high occupant safety as well as a degree of torsional stiffness hitherto unattained in open-top vehicles. This leads to outstanding ride characteristics of the kind otherwise found only in closed-top super sports cars.

The puristic top is suitable for high speeds

The exceptional qualities of the Roadster are attributable also to the fully retractable top, which blends harmoniously into the flowing lines of the SLR McLaren. Its newly developed roof material, which is available in three different colours, not only guarantees complete suitability for everyday use in all weathers, but also endows the high-performance sports car with characteristics that are exception-ally unusual in a roadster. For example, at 332 km/h, the maximum speed is at the high level of the coupé version. Conversation is still possible at well over 200 km/h on open-air journeys thanks to the favourable aeroacoustics.

The roof opens and closes semi-automatically in less than ten seconds, thereby combining the desire for convenience with the puristic character of the roadster. To open, the roof merely needs to be unlocked from the windscreen frame and be briefly raised, after which it folds away electrically. Since an aluminium cover is integrated into its front section, the roof elegantly closes off the top when re-tracted.

Sophisticated aerodynamics and racing-type chassis

In the wind tunnel, the Roadster has been optimised for high speeds with regard to handling, aeroacoustics and aerodynamics. It likewise employs the aerodynamic concept already known from the coupé version, featuring an airbrake integrated into the access lid and a diffusor in the rear bumper to provide increased downforce on the rear axle.

The open two-seater is equipped with a racing-type chassis featuring high-performance carbon-ceramic brake discs, thereby setting extremely high stan-dards. Its front-mid-engine provides for optimum weight distribution. With 460 kW/626 hp and a maximum torque of 780 Nm, the AMG V8 compressor engine, which is coupled to an AMG Speedshift R five-speed automatic transmission, accelerates the Roadster from zero to 100 km/h in 3.8 seconds.

Unique safety and exclusive fittings

A high degree of safety is ensured by unique carbon-fibre crash elements, steel-reinforced A-pillars and two fixed roll-over bars. The comprehensive specification also features adaptive airbags, knee and side airbags as well as seat belt tensioners and a tyre-pressure monitoring system.

The exclusive standard equipment includes semi-aniline-leather-upholstered carbon-fibre bucket seats which can be individually adapted to the driver and front passenger by means of differently sized seat pads; dual-zone automatic air-conditioning; a high-quality BOSE premium sound system; a multifunction sport steering wheel with gear-change paddles, and a navigation system with integral radio and CD player.

The new Mercedes-Benz SLR Roadster, like the coupé, is produced at McLaren's Formula 1 factory in Woking, England, in accordance with stringent Mercedes-Benz quality criteria and will be available as from September 2007.

-----

Model concept and design

It was in the mid-1950s that the Mercedes-Benz SLR acquired a hallowed status in the world of motor racing. Quite apart from its long list of legendary race victories, its avant-garde technology and thrilling design instantly transformed it into a blueprint for all high-calibre Gran Turismo touring cars. The designation " SLR " has possessed a magical symbolism ever since.

Charisma and cutting-edge technology are also the hallmarks of the new Mercedes-Benz SLR McLaren Roadster, which will celebrate its world premiere in autumn 2007. Like the Coupé version, with which Mercedes-Benz and its Formula 1 partner McLaren have successfully established themselves in the exclusive super-sports car class since 2003, the new high-performance Roadster was designed and developed on the basis of two showcars presented in 1999. It is with these that Mercedes-Benz first reinvigorated the tradition of the mystical SLR models after several decades – and introduced both a fixed-roof coupé and an open-top roadster version to the public.

The new Mercedes-Benz SLR McLaren Roadster also shares its basic concept with the Coupé: in order to obtain optimum weight distribution for flawless handling dynamics and high braking stability, the Mercedes-Benz SLR McLaren Roadster is designed as a front-mid-engined sports car with the drive unit placed behind the front axle, a suspension derived from motor racing and the same, powerful AMG supercharged V8 engine developing 460 kW/626 hp. The result is outstanding roadholding and handling characteristics, a top speed of 332 km/h and acceleration from zero to 100 km/h in just 3.8 seconds.

The new SLR Roadster differs from the Coupé variant in that more than 500 components are either new or improved. Apart from the soft top and its operation these mainly include the boot lid, the now frameless swing-wing doors, the rear wings, the A-pillars and windscreen surround, the rollover bars and the seat belt anchorage points. Most of these modifications and new developments were necessary to integrate the fabric roof perfectly into the vehicle structure. Despite the fact that the Roadster comes with a fully retractable soft top to fuse pure open-top driving pleasure with the ultimate in performance, its occupants by no means have to compromise in terms of comfort or everyday practicality. This unrivalled combination makes it very special even in the world of super-sports cars.

The new Mercedes-Benz SLR McLaren Roadster owes its exceptional status among open high-performance sports cars to its motor racing genes and the uncompromising use of high-tech materials that - despite all their inherent benefits - are generally only ever found in a few individual components of even premium series-production cars, if at all, owing to the high costs and elaborate manufacturing processes involved.

This is particularly true of the high-strength yet lightweight carbon-fibre composite materials (CFRP) that are used. Mercedes-Benz and its Formula 1 partner, McLaren, have gathered many years of experience with this material which is commonly used in the aerospace industry. In an impact, carbon fibres have a level of energy absorption that is four to five times higher than that of steel or aluminium, while the weight advantage of this high-tech material over steel is around 50 per cent.

The new high-performance Roadster capitalises on all of these benefits. As in the Coupé version, and apart from two aluminium engine frames, its body is completely made of this exotic material. This complex carbon-fibre technology has furthermore undergone intelligent redevelopment for the Roadster's monocoque. The result is low weight as well as exemplary energy absorption courtesy of unique carbon-fibre crash structures, which translates into excellent occupant safety, plus a level of torsional stiffness that is unprecedented for an open-top car. This gives rise to the sort of scintillating performance that is normally the preserve of super sports cars with a fixed roof.

Dramatic lines and top-quality appointments

As in the Coupé, the exciting design of the new Roadster was inspired by the SLR models of the 1950s and the Formula 1 Silver Arrows. At its centre, the front end is dominated by the striking, arrow-shaped contour it shares with the Formula 1 Silver Arrows, which encloses the Mercedes star and unmistakably confirms its tradition and heritage. The two wings extending below it ensure a high downforce at the front axle, and decisively contribute to the safe, racetrack-bred handling of the new SLR Roadster.

The designers of the SLR also repeated the wing theme in other areas of the body to provide design continuity: wing-shaped vanes also divide the areas between the headlamps and the front end contour, act as stems for the exterior mirrors and embellish the rear light clusters, where the LED indicators are seated in two projecting, superimposed vanes.

Powerful contours and athletic muscles

The wide, flat bonnet extends back from the large air dam, its rear edge ending at the bases of the A-pillars to provide space for the very deep windscreen. The rounded twin headlamps give way to strong contours which extend over the wings like powerful muscles and combine with tightly drawn lines to signify raw power.

The silhouette of the SLR Roadster shows muscular proportions, with lines that are intentionally reminiscent of the Mercedes sports cars of yesteryear. It is characterised by a long bonnet, a tight waistline, a compact passenger compartment with a striking fabric soft-top and a short rear end with large, elegant LED rear light clusters.

Side "gills" and wide-opening swing-wing doors

It is particularly the side aspect that reveals the great motor racing tradition on which the design of the new high-performance Roadster is based, as the SLR legend lives on in the form of large, vaned air vents. These " gills " are far more than a design feature, however, as their function has always been to ventilate the engine compartment.

The Roadster has also been given another unmistakable feature that characterised the roadgoing coupé version of the legendary SLR racing sports car designed by the former head of the Mercedes test department, Rudolf Uhlenhaut, in 1955, namely swing-wing doors. In this modern interpretation the frameless doors of the Roadsters are not however attached to the roof, but to the front roof pillars where they are able to swing forward at a large angle. This concept ensures the striking visual impact of the 1950s cars while considerably enlarging the door aperture for convenient access and egress.

Puristic fabric soft-top with coupé qualities

The compact fabric soft-top sits snugly on the carbon-fibre bodywork to enclose the passenger compartment, accentuating the flowing contours of the Roadster. As a result the silhouette appears even longer than that of the Coupé version, with even more striking lines – especially when the roof is open of course. Integrating the soft top harmoniously required painstaking, detailed work by the designers, who carefully smoothed the transitions between the boot lid, roof and rear bulkhead so that whether the soft-top is open or closed, this area too appears to have been cast from a single mould.

The soft top retracts fully in order not to disrupt the flowing contours when driving with the roof down. To open the roof, the driver simply has to release the catches in the roof frame and lift it up slightly; the side windows then open and, once a concealed switch in the centre console has been pressed, the roof folds together in a "Z" and stows itself away behind the seats on a level with the boot lid. For safety reasons, the soft-top can only be operated when the car is stationary. Drivers are able to make the very most of every break in the weather as the semi-automated mechanism opens and closes the roof in just over ten seconds flat, thereby harmonising the desire for convenience with the purist nature of this top-class Roadster.

The front section of the roof incorporates a fixed header bow made from aluminium. Not only does this give added stability, it also dispenses with the need for an additional cover when the roof is down, as it lies perfectly flush with the tail's contours. This is once again a reflection of the puristic character of the SLR Roadster.

Furthermore, the hard roof shell, the short spacing between the bows and the optimum attachment of the roof fabric give the soft top on the SLR Roadster very different properties from the majority of convertible roofs. There is none of the usual ballooning at high speeds; even at top speed, its contour alters by just a couple of millimetres at the rear. Drivers of the new high-performance two-seater from Mercedes and McLaren can therefore push it all the way to its top speed far beyond the 300 km/h mark with complete peace of mind, even with the roof closed.

However puristic the roof's design may appear it is in actual fact highly elaborate, with three carefully harmonised layers that ensure excellent insulation and therefore pleasant levels of comfort, even in poor weather.

Three roof colours and an intriguing light effect

For the soft top the designers chose a new, high-quality woven material with unique properties. This features differently coloured threads – black and coloured – for the warp and weft, creating an intriguing light effect that varies with the angle of vision and a striking yet very elegant-looking finish, whose unusual surface ties in fittingly with the car's carbon-fibre structure. The soft- top is available in three fabric colours - anthracite-black, red-black and beige-black – and can therefore be perfectly coordinated with the range of 13 paint finishes and the chosen interior colour. As an optional alternative to the silver brake callipers, Mercedes-Benz also offers red or gold-painted callipers to accentuate the high-tech nature and exclusivity of the car even further.

Despite the additional weight caused by the roof structure, the overall weight of the car has hardly increased at 1825 kilograms (ECE standard). The capacity of the boot is 204 litres (DIN), both with the roof open or closed. This is sufficient to stow travel bags even for open-top journeys.

Honed for high speeds in the wind tunnel

In view of the outstanding performance of the Mercedes-Benz SLR McLaren Roadster, which is capable of speeds well in excess of the 300 km/h mark, particular attention was naturally paid to the aerodynamics. The Roadster's handling, aero-acoustics and aerodynamics were optimised for high-speed driving in the wind tunnel, with the emphasis on safe, stable handling at high speeds. This meant that the body must not generate lift, but rather a downforce that would press the car down onto the road and ensure optimal adhesion.

Like the Coupé, the Roadster features an almost completely smooth underbody, a front splitter, a six-channel rear diffuser and special air deflectors at the rear wheels. It therefore follows tried and tested design principles derived from Formula 1. These ensure that the airstream beneath the vehicle flows as smoothly as possible to create a speed-dependent downforce. This unique concept keeps the axle load perfectly balanced while maintaining a high, uniform downforce at the front and rear axles.

In the Roadster too, these forces are augmented by a speed-regulated Airbrake integrated into the boot lid. When a speed of 95 km/h is reached, this automatically raises its approx. 1000 square centimetre cross-section into the slipstream at an angle of ten degrees, thereby increasing the downward pressure on the rear axle. This also gives the SLR outstanding stability when braking from high speeds. The extending spoiler also acts as an airbrake: if the driver steps heavily on the brake pedal, the rear spoiler rises to an angle of 65 degrees to increase the air resistance and move the aerodynamic centre of gravity further to the rear. Both have the effect of improving braking performance even further.

In most situations the electronics automatically control the airbrake as required. However, the driver may also adjust the setting manually by pressing the switch in the centre console to raise the rear spoiler to an angle of 30 degrees.

There has only been a slight increase in the Cd figure for the Roadster compared to the Coupé, measuring 0.376 with the roof closed and 0.4078 with the roof open (airbrake in 10° setting for both measurements).

The special underbody design of this high-performance sports car also includes the striking exhaust pipes on each side of the vehicle: a conventional exhaust system would have made a smooth underbody and an optimal diffuser design difficult to achieve.

The aerodynamics engineers also took great care to make the Roadster a shining example in terms of its aero-acoustics. Painstakingly meticulous work on the soft top bay, on the roof itself and on the transition point from the soft top to the body have cut wind noise substantially. As an example, the distance between the roof when closed and the boot lid was fine-tuned with such precision that no additional sealing lips are required. The airstream felt in the passenger compartment when the roof is down is furthermore reduced to great effect by a Plexiglass wind-deflector bearing the SLR lettering, that measures little wider than a hand and is inserted between the two rollover bars. Thanks to the sophisticated aerodynamics and the highly effective wind-deflector there is very little turbulence even at speeds in excess of 200 km/h.

Racing-style interior with a new dimension in comfort

The interior of the Mercedes-Benz SLR McLaren Roadster was designed to provide a combination of a puristic sports car feeling and extraordinary luxury. Carefully chosen materials such as carbon fibre, aluminium and leather of the highest quality and exclusivity dominate the passenger compartment of the Roadster, underlining the unmistakable attributes of a classic Gran Turismo: outstanding ride comfort and uncompromising concentration on ultimate, dynamic driving pleasure.

Despite its luxurious and comfortable appointments, the Mercedes-Benz SLR McLaren Roadster clearly shows that the designers defined its interior dimensions with the requirements for a high-performance sports car firmly in mind. The dimensions of the passenger compartment are subject to the extraordinarily high requirements of first-class handling dynamics, and are therefore compact, or rather tailor-made. Nonetheless there is a feeling of spaciousness in the two-seater, due in part to the low seating position which also lowers the centre of gravity in the interests of optimal handling characteristics. To compensate, the backrests of the carbon-fibre bucket seats are angled at 28 rather than 25 degrees versus the seat cushions to allow a sporty seating position.

Replaceable seat cushions for individual adjustment

Thanks to their multi-layered, composite carbon-fibre construction, the light-weight, one-piece seats of CFRP are roughly 25 percent lighter than conventional car seats. Replaceable seat cushions allow the seat contours to be adapted to the anatomy of the driver in five sizes, and to that of the passenger in four sizes. The one-piece CFRP seat shell is linked to an electric seat adjustment mechanism at four points, allowing the seats to be adjusted to suit personal requirements with respect to fore-and-aft position (by 130 millimetres), height (by 41 millimetres) and angle (up to 9.6 degrees).

Two-tone colour scheme and new materials

The two-tone interior colour scheme, for which only the finest materials such as high-grade leather and fine, pearl velour carpeting are used, always features a dark-coloured dashboard to prevent distracting reflections, while e.g. the seats, centre door panels and the tunnel lining are in a contrasting colour depending on the chosen interior. The rollover bars are lined in black leather.

A particularly exclusive material was specially developed for the Roadster, namely braided leather. This can be used for the centre panels of the seats on request, and not only provides a high level of climatic comfort but also ideally complements and enhances the sophisticated carbon-fibre technology used throughout the car.

Cockpit with a high-quality chronometer look

Once the electronic ignition key is inserted, the SLR awakens into life. A starter button in the boss of the solid metal shift lever begins to glow red. Thumbing open the covering mesh and pressing the glowing starter button brings the enormous power of the supercharged AMG V8 engine to life. The cockpit is intentionally minimalist in design, in line with motor racing philosophy. Easily legible markings on a dark background which were specially styled for the SLR characterise the classically elegant chronometer design of the instruments, immediately signifying outstanding precision.

Multifunction steering wheel with paddles for rapid gear changes

The three-spoke steering wheel with a diameter of 382 millimetres is adjustable for reach by 60 millimetres and for height by 2.7 degrees. Aluminium shift paddles larger than those in the Coupé are mounted on the reverse of the steering wheel spokes. These enable the driver to change gears without taking his hands from the wheel – in true Formula 1 style.

In addition to the switches for the airbrake and gearshift programme, the roof operating switch is recessed into the centre console of high-grade aluminium. The centre console also accommodates the radio with navigation system and the air conditioning controls.

Automatic climate control with sensors for sunshine, air quality and humidity

Despite its puristic motor racing character, the Mercedes-Benz SLR McLaren Roadster is equipped with an automatic climate control system which leaves no wish unanswered with respect to efficiency, practicality and ease of operation. The Audio 30 APS unit combines a radio, CD-player and controls for the CD changer and navigation system with dynamic route guidance in a single, clearly laid out unit. Perfect audio quality is ensured by the Bose sound system, which is specially configured for the acoustic conditions in the open-top SLR Roadster. Its sophisticated electronics not only compensate interfering frequencies, but also use a microphone to constantly register road noise and adjust the sound volume without intervention by the driver.

Other integrated features include a fixed mobile phone installation and all the aerials required for radio and telephone reception, as well as operation of the satellite navigation system.

-----

Exclusive standard appointments

- Adaptive airbags

- Aero-wipers

- Airbrake integrated into the boot lid

- AMG Speedshift R five-speed automatic transmission with three manual shift programmes

- AMG sports exhaust system with twin sidepipes on each side

- Aerial for car phone

- Anti-lock braking system (ABS)

- Acceleration Skid Control (ASR)

- Audio 30 APS (navigation system with integral radio and CD player), CD changer and GSM telephone

- Outside temperature display

- Courtesy lights in the doors

- Automatic tyre pressure monitoring

- Bi-Xenon headlamps

- Carpets with SLR logo

- Brake Assist (BAS)

- One-piece carbon-fibre bucket seats, electrically adjustable, driver’s seat in five different sizes with replaceable seat pads

- CFRP crash structures at the front end and rear

- Diffuser integrated into the rear bumper

- Double wishbone suspension

- Anti-theft alarm system

- Electronic Stability Programme (ESP®)

- Electrically adjustable steering column

- Electrohydraulic brakes

- Headlamp Assist

- Power windows

- Front airbags with two-stage gas generators

- AMG Speedshift five-speed automatic transmission with three programmes and choice of manual shift speed

- Belt tensioners and belt force limiters

- Head/thorax sidebags in the doors

- Heated glass rear window

- Interior lighting with night design

- Ceramic brake discs

- Automatic child seat recognition

- Knee airbags

- Supercharged engine, 5.5 l V8

- Choice of 13 paint finishes

- Leather upholstery and leather interior

- Electrically adjustable steering column

- LED brake lights

- Monocoque and carbon-fibre body

- Engine with four metal catalytic converters for exhaust emissions below the EU 4 limits

- Multifunction sports steering wheel with enlarged aluminium shift paddles

- Navigation system with dynamic route guidance

- Fog lamps

- 18-inch wheels in a ten-spoke design

- Rain sensing wipers

- pressure monitoring system

- Trip computer

- Heated windscreen washer system

- Headlamp cleaning system

- ELCODE locking system

- BOSE sound system

- Sports bucket seats of carbon-fibre with semi-aniline leather seat covers in 5 (4) different sizes for the driver (passenger)

- " Panama " semi-automatic fabric soft-top, two-tone in three colours - black – anthracite, black – red, black - beige

- Cruise control with Speedtronic

- Touch shift

- Tirefit tyre sealing kit with electric pump

- Fixed rollover bars behind the seats

- Service interval display

- Central displays in the instrument cluster

- Central locking with remote control

- Two-zone automatic climate control

Optional extras (selection)

- 19-inch wheels in a turbine design

- Brake callipers painted in gold or red

- Black carbon-fibre inserts in the interior

- Silver Arrow leather in 13 colours with embossed SLR logo

- Braided Composition leather

- Contrasting seams in 300 SL red, orion grey or black

- Two-tone steering wheel (matching second interior colour)

- Floor mats with leather piping in the second interior colour

- Provision for mobile phone with universal interface

-----

Body and safety

Many things seem impossible – until someone proves otherwise. The new Mercedes-Benz SLR McLaren Roadster rebuts a long-standing prejudice, by demonstrating that an open-top high-performance sports car can be every bit as torsionally stiff as a closed coupé. The proof of this is outstanding handling characteristics and undiluted open-top driving pleasure to way beyond the 300‑km/h mark, paired with excellent comfort on long journeys and unrestricted practicality for day-to-day driving, which together makes the new Roadster an open-top super sports car with a difference.

Underpinning all of this is the systematic and intelligent use of high-tech materials for the body and safety technology. As in the Coupé, the bodyshell of the high-performance Roadster, including the front-end and rear-end structure, the passenger cell, the swing-wing doors and the bonnet, is made entirely from carbon-fibre reinforced plastic. This lightweight yet extremely rigid material originated in the aerospace industry, and has also proven its benefits in today's Formula 1 racing cars. Compared to steel, the high-tech material represents a weight saving of around 50 per cent.

Scientists at DaimlerChrysler Research played an instrumental role in the development and transfer to series production of carbon-fibre materials in the aviation industry, where they are used predominantly for fins, rudders and landing flaps. Quite apart from this, the experts at Mercedes-Benz and McLaren have gained extensive experience with this exotic material, as well as acquiring tremendous expertise in its processing, from their work on racing cars. This invaluable know-how has also been put to good use in the new Mercedes-Benz SLR McLaren Roadster, whose entire body harnesses the benefits of carbon-fibre reinforced plastics (technical abbreviation: CFRP). Only the two engine mounts are made from aluminium. Even in super sports car circles, such extensive use of this expensive, high-tech material is still something of an exception.

Carbon-fibre materials for low weight and high torsional stiffness

Mercedes-Benz and McLaren opted for the extensive use of CFRP because of the evident beneficial effects carbon fibres have on rigidity and energy absorption. What's more, components made from this material weigh up to 50 per cent less than comparable steel components offering the same strength and as much as 30 per cent less than aluminium components. This makes CFRP the material of choice for manufacturing high-performance cars, because lower weight not only means lower fuel consumption but also outstanding transfer of power to the road. Owing to the consistent use of carbon-fibre-reinforced plastics, the primary structure of the Mercedes-Benz SLR McLaren Roadster is indeed considerably lighter than the conventional steel construction of a comparable front-mid-engined vehicle.

Intelligent advance in carbon technology

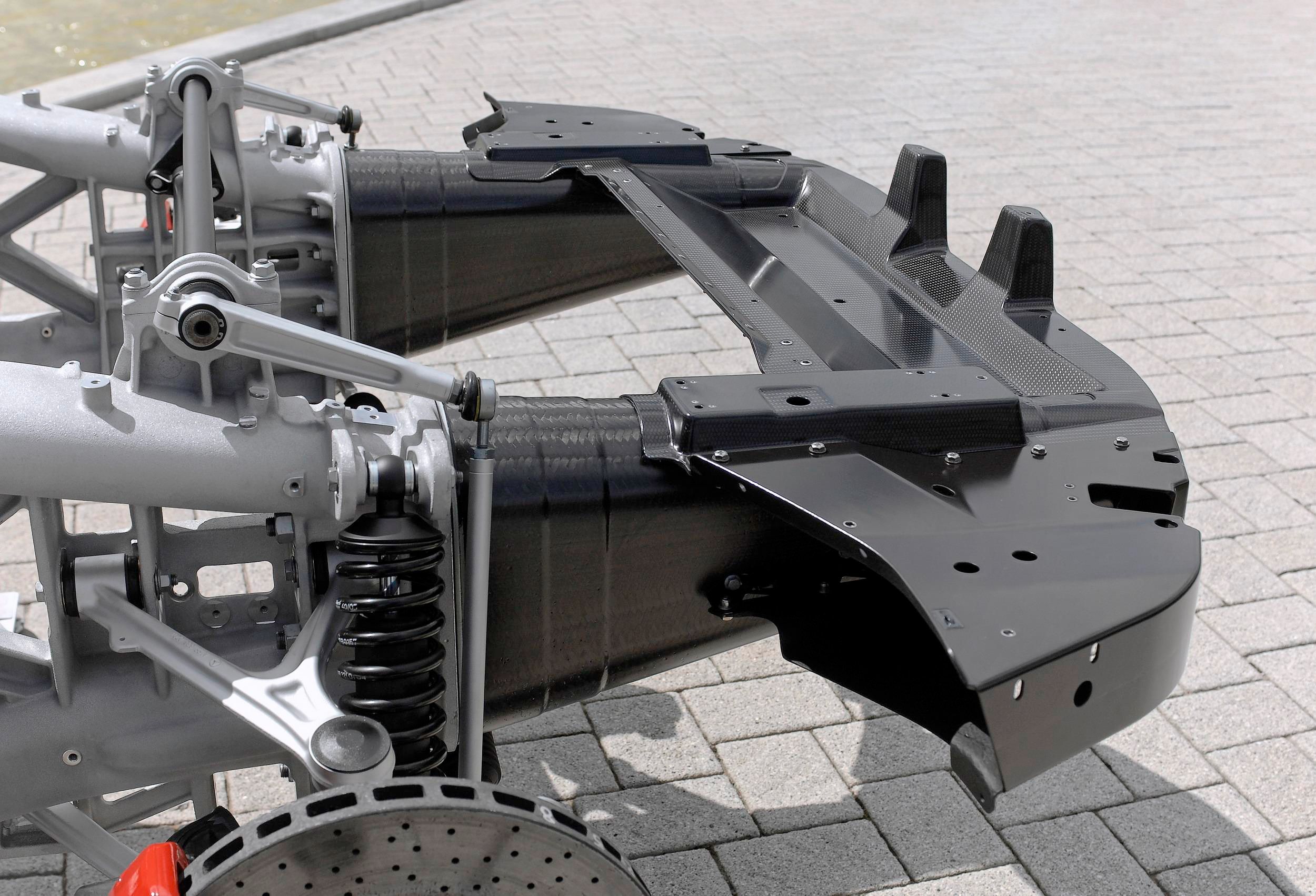

Compared to the Mercedes-Benz SLR McLaren, which marked the first ever use of carbon-fibre technology to such a large extent in series car production, the way in which the material is applied has undergone further advancement for the Roadster. By optimising the arrangement of the different layers of carbon-fibre matting, the engineers were able to minimise the unavoidable weight increase produced by the Roadster's roof without any loss of strength. This allowed the high-performance Roadster to retain an exceptionally high, coupé-like level of torsional stiffness that is unprecedented for a cabriolet, but without any significant increase in weight despite the mechanism for the soft top.

The roof's design meant there were other components in the Coupé that the design engineers were unable to transfer directly either: the A-pillars with their integral steel reinforcements, as well as the windscreen frame, the rear wings, the boot lid and the swing-wing doors have all been redesigned, although they continue to be made from carbon-fibre-reinforced material of course. In contrast to the Coupé, the unmistakable swing-wing doors inspired by the legendary SLR racing car from 1955 - or the Uhlenhaut Coupé as it is affectionately known - have a frameless design on the new Roadster so as not to lose any of that open-top driving sensation. As in the Coupé, the doors are attached to the front roof pillars and swing forwards and upwards through an angle of 107 degrees when they open. This door concept makes for a sensational appearance.

CFRP produces high energy absorption values

Apart from their extreme stiffness, the state-of-the-art carbon-fibre-reinforced materials are also renowned for their excellent energy absorption. The absorption capacity is around four to five times higher than that of metallic materials. Formula 1 constructors have been exploiting this quality for several years, manufacturing the crash structure of their racing cars from CFRP. It is primarily as a result of this that the risk of injury in high-speed accidents in this Blue Riband motorsport event has dropped significantly.

The monocoque – or, to put it another way, the passenger cell – of the new Mercedes-Benz SLR McLaren Roadster is also made entirely from this high-tech material. In the event of a head-on, side-on or rear-end collision, it offers the occupants a highly rigid and hence secure survival space.

The new A-pillar, with its additional internal reinforcement in the form of a high-strength steel tube, also has a role to play here. The arrival of the Mercedes-Benz SLR McLaren Roadster thereby marks the series-production debut of a highly complex steel/carbon-fibre compound that combines high strength with the elasticity required for safety reasons. Fixed rollover bars behind the seats complement the safety concept. They ensure the occupants are afforded an outstanding level of protection even if the vehicle should turn over.

Carbon-fibre crash elements in the front structure

At the rear, two internal side members made from laminated carbon fibre and a robust cross member assume the task of energy absorption in the event of a crash. In an impact from the side, the occupants are protected by the broad, low-set sills containing multi-shell deformable elements made from specially reinforced carbon-fibre materials as well as two aluminium sections incorporated into each door. The sturdy shell of the SLR seats also has a protective function in a rear-end or side-on collision and is likewise built from highly resilient carbon-fibre material.

It is in the front-end structure of the SLR bodyshell that the impressive safety properties of the innovative fibre composite are particularly evident. Here, two conical carbon-fibre-reinforced plastic elements - each approximately 620 millimetres in length, weighing just 3.4 kilograms and consisting of an encased inner web - are enough to absorb the full impact energy in a defined frontal collision without exceeding the tolerable deceleration threshold for the occupants. The carbon-fibre composite members are bolted onto the aluminium structure of the engine mounts behind them. This means that the Roadster, just like the Coupé, has a front crash structure manufactured entirely from carbon fibre.

In a collision, the fibres of the CFRP elements shred from front to rear, absorbing the energy of the impact with a constant rate of deceleration. Thanks to this steady deformation behaviour and the high-strength monocoque, the energy absorption of the CFRP side members can be precisely calibrated. The engineers achieve this, for example, by creating a constantly changing cross-sectional area for the components. This fine tuning means that the deceleration values result not only in predictable energy absorption behaviour but also in a weight advantage, because this design uses only as much material as is actually needed.

Restraint system with adaptive airbags, sidebags and kneebags

A state-of-the-art restraint system comprising six airbags, belt tensioners and belt force limiters completes the SLR Roadster's elaborate safety concept, ensuring that it meets all Mercedes standards in this regard too.

In the event of a head-on collision, the electronic control unit first triggers the high-performance belt tensioners, which can pull up to 15 centimetres of loose belt strap taut in fractions of a second, reducing the forward displacement of the occupants caused by the impact. The Mercedes-Benz SLR McLaren Roadster is also fitted with kneebags, which – together with the two-stage airbags – provide a large protective cushion for the driver and passenger in a frontal collision, complementing the effect of the seat belts and belt tensioners.

Upfront sensors for rapid airbag deployment

The belt tensioners are also activated if a roll-over situation is detected, triggered by a roll-over sensor which reliably recognises this type of accident and relays its data at lightning speed to the central control unit for the restraint systems. The sensor is located in the centre tunnel.

A sophisticated system of sensors also allows adaptive control of the front airbags, which deploy according to the severity of the accident. If the sensors register a light head-on collision, they each trigger just one chamber of the two-stage gas generators so that the 64-litre driver airbag and 125-litre passenger airbag are deployed with a lower internal pressure. If the sensors register an accident of a greater severity, the electronics also trigger the second chamber of the gas generators and the airbags inflate with a higher pressure.

Two upfront sensors on the radiator cross member fulfil an ancillary function for this adaptive deployment of the restraint systems. Thanks to their forward positioning in the front structure, they detect the severity of the impact even earlier and more precisely. The deployment algorithm uses both this signal and the signal from the central crash sensor on the centre tunnel.

While the occupants sink safely into the airbags, the belt force limiters reduce the force exerted by the belt strap on the upper body, further decreasing the risk of minor chest and shoulder injuries.

Sidebags with additional protection for the head

Protection in the event of an impact from the side is optimised by the integral sidebags in the doors. These cushion both the head and the upper torso, which is why they are referred to in specialist circles as "head/thorax bags". In a side-on collision, this specially developed sidebag rips open a seam above the armrest and inflates within milliseconds to form an asymmetrically shaped airbag, the upper edge of which extends higher than that of conventional sidebags. The airbag's design reduces the risk of the head hitting against the side window or any object which may penetrate into the interior.

The automatic child seat recognition system, developed by Mercedes-Benz, is also part of the SLR's standard equipment. It deactivates the passenger airbag if one of the special child seats from the Mercedes-Benz accessories range is installed on the passenger seat. These child seats have a transponder system which receives and responds to signals from two antennae in the seat upholstery. As a result of the exchange of data, the airbag electronics recognise that a child seat is fitted and deactivate the airbag on the passenger side since its deployment is not desirable in these circumstances. The belt tensioner and sidebag remain activated, offering the young passenger additional protection in the event of an accident.

-----

Engine and transmission

An abundance of power and high-tech features from the world of motorsport – these are the defining characteristics of the V8 engine in the Mercedes-Benz SLR McLaren Roadster, with its 5.5-litre displacement, a cylinder angle of 90 degrees, screw-type supercharger and a crankshaft supported by five bearings . Which all means that the V8 power unit developed by Mercedes-AMG fits perfectly into the high-performance concept of the new open-top Gran Turismo.

Key engine data at a glance:

- Cylinder arrangement V8

- Cylinder angle 90o

- Valves per cylinder 3

- Displacement 5439 cc

- Bore/stroke 97.0/92.0 mm

- Cylinder spacing 106 mm

- Compression ratio 9.0 : 1

- Output 460 kW/626 hp at 6500/min

- Max. torque 780 Nm at 3250-5000 rpm

- Engine weight 232 kg

- Power/weight ratio 1.9 kW/kg

From a mere 1500 rpm, the SLR powerplant delivers in excess of 600 metres of torque, rising to 700 metres at 2000 rpm. The maximum of 780 metres is available from 3250 rpm and remains constant over a broad rev range up to 5000 rpm. The sublime torque delivery is coupled to the agile responsiveness of a sporty engine whose high-performance character is never in any doubt: a peak output of 460 kW/626 hp says it all. The SLR is thereby endowed with what is currently one of the most powerful engines to be found in a series-produced sports car, and achieves class-beating performance figures as a result.

- 0–100 km/h 3.8 s

- 0–200 km/h 10.9 s

- 0–300 km/h 30.8 s

- Top speed 332 km/h

Power from screw-type supercharger

To ensure good cylinder charging, the engine has a belt-driven supercharger between the two banks of cylinders featuring two screw-shaped aluminium rotors that are Teflon-coated to keep friction losses to a minimum. Its innovative technology allows a significantly higher charge pressure than conventional belt-driven chargers because the two rotors can attain a top speed of around 23,000 revs per minute, forcing air into the intake system of the 5.5-litre powerplant at a maximum overpressure of 0.9 bar. This means that they compress around 1850 kilograms of air into the eight combustion chambers every hour – which is as much as 30 per cent more than the figure achieved by rival charging systems.

In order to maintain the greatest possible efficiency at all times, the AMG engineers created an intelligent engine management system which regulates the operation of the screw-type supercharger according to engine speed and load. Consequently, the charger is only called into action when it is really needed. Nevertheless, the system ensures that maximum power is available the instant it is summoned by a squeeze of the accelerator. This prompts the electronics of the engine management system to trigger an electromagnetic coupling, which immediately activates the supercharger, which is driven by a separate poly-V-belt. Because the charger delivers its output in fractions of a second, even the most perceptive driver will not notice the non-supercharged phases. The charger system's air recirculation flap is opened under partial throttle conditions to help reduce fuel consumption.

Two intercoolers with separate water circuit

In addition to the supercharger, the electronics also monitor all other variables relevant to the engine – including both the powertrain management for the pedal-sensitive drive characteristics and the implementation of spontaneous interventions by the transmission or ESP®. The electronics also ensure optimum control of the water circuit for the intercooling system, as efficient intercooling is essential for maximising output. This is because cold air is denser than warm air and therefore contains significantly more oxygen for combustion. In the Mercedes-Benz SLR McLaren Roadster's V8 engine, two separate intercoolers are responsible for this key task – one for each bank of cylinders. This ensures that loss of pressure is very low.

The engine-mounted intercoolers operate on the highly efficient principle of an air-to-water heat exchanger: after being compressed and hence heated by the supercharger, the air is cooled down via the system's own, separate water circuit – making the process independent of the ambient temperature. This enables the V8 to deliver its maximum output and torque spontaneously at any time.

However, the tremendous output of the eight-cylinder engine in the new SLR Roadster not only demands effective cooling of the combustion air, it also results in an overall increase in engine cooling requirements. The engineers made allowance for this by incorporating generously proportioned cooling air inlets and outlets as well as a powerful 850-Watt suction fan.

Crankcase with dry-sump lubrication

The Mercedes-AMG GmbH engineers also applied their extensive experience in the world of motorsport and in the design of high-performance engines to other details of the SLR powerplant. The entire engine housing, for example, and the enclosed bottom section of the crankcase are cast in aluminium. Each crankshaft is finely balanced and is supported by five bearings made from a high-endurance material for lasting transfer of the immense forces generated by the supercharged engine.

The pistons are forged and are therefore only manufactured in very small numbers. Like the forged lightweight connecting rods, they are precision gauged and weighed then allocated to the individual engines in such a way as to produce minimal mass balancing tolerances. The pistons slide in extremely durable, wear-resistant and friction-optimised barrels made from a special compound which is otherwise only used in motor racing. Dual oil injection ensures efficient piston cooling.

The design of the powerplant's oil cooling system also draws on the experience gathered at the race track: a sophisticated dry-sump lubrication system with an oil capacity of around eleven litres combines with a five-speed oil suction pump and a two-speed oil pressure pump to maintain reliable lubrication under the full spectrum of driving conditions. An important secondary effect of the dry-sump lubrication technology, which is usually only found in racing cars, is that it reduces the engine's overall height, allowing it to be installed lower down and producing a low centre of gravity that favours dynamic handling.

In line with the customary practice at Mercedes-AMG, each SLR engine is manufactured by hand. In order to attain the very highest quality, the principle of 'One man, one engine' is applied. This means that each powerplant is the responsibility of one AMG engineer, who carries out the entire engine assembly process – from installing the crankshaft in the engine block and assembling the camshafts and the supercharger, right through to the cabling.

Powerful high-pressure pumps in the tanks

The SLR's high-performance engine draws its fuel from two interconnected aluminium tanks. In order to keep the centre of gravity as low as possible in the interests of exceptional handling dynamics, the tanks are installed low down on the left and right in front of the rear axle. The tanks, which have a total capacity of 97 litres (of which twelve litres form the reserve), are equipped with two integral high-pressure fuel pumps. These are controlled by the engine management system and ensure that the fuel supply matches the engine speed and load. Once again, a highly effective solution specific to the SLR was developed: one pump operates constantly while the second only cuts in as required.

Four metal catalytic converters for efficient emissions control

Secondary air injection and dual ignition give the engine the prerequisites for low exhaust emissions. A sophisticated exhaust system complements these measures: the cascade-design two-pipe system consists on both sides of a close-coupled firewall catalytic converter plus, in the same housing, a main catalytic converter with a special precious-metal coating. The state-of-the-art metal design allows extremely thin walls, resulting in a very low exhaust backpressure. Thanks to its cutting-edge engine management and emission control technology, the V8 engine in the new SLR meets the stringent EU4 emissions limits as well as the current US limits.

On each side of the vehicle, the catalytic converter housing opens into a rear silencer which flows into two stainless-steel tailpipes with a diameter of 60 millimetres just behind the front wheels. These sidepipes – a further reminder of the 1950s SLR racers – pave the way for a smooth-surfaced underbody, which is instrumental in giving the new Mercedes-Benz SLR McLaren Roadster its first-rate aerodynamic properties. The silencers are folded several times into precisely calculated acoustic sections which produce the Roadster's distinctive, thrilling engine sound. The volume of each silencer is 19.6 litres.

Manual transmission program for shift times worthy of a racing car

Likewise designed for high performance, the five-speed automatic transmission was developed by Mercedes-Benz and has been used successfully in several exceptionally powerful models. It has been specially optimised for very high torque and also offers the driver the option of choosing between different shift characteristics. The transmission transmits the engine's power via a finely balanced aluminium and steel powertrain to the differential and the rear axle.

It includes the Speedshift system that was developed by Mercedes-AMG for particularly sporty motoring and also offers a wide range of functions in the new SLR Roadster. Drivers can decide, for example, whether to leave the gearshift work to the automatic transmission or to shift gears manually. They are also able to select the shift speed, which determines how sporty the gearshifts are. A rotary switch in the centre console offers a choice of three program settings: "Manual", "Comfort" and "Sport". The activated programme is indicated in the instrument cluster display by the letters "M", "C" or "S".

"Comfort" and "Sport" are automatic shift programs which, as the names indicate, place the emphasis either on comfort or on a more sporty drive. In "Manual" mode, on the other hand, the driver can select the five gears either using the shift paddles on the steering wheel or the selector lever's Tipfunction. When "Manual" is selected, there is also the option of choosing between three shift-speed levels for fine-tuning a sporty driving style:

- Level I = "Sport"

- Level II = "Supersport"

- Level III = "Race"

The higher the level, the shorter the shift and response times inside the automatic transmission, and hence the shorter the gearshifts themselves.

-----

Suspension

Highly advanced motor racing technology, high-performance control systems and state-of-the-art materials – a unique combination which helps the Mercedes-Benz SLR McLaren Roadster to score top figures in three key handling criteria: agility, active safety and comfort. In the process, the SLR suspension lives up to all the expectations a discerning car driver might have of a Gran Turismo bearing the Mercedes star.

The axle design is evidently the handiwork of experienced racing car developers, with double wishbones assuming the task of wheel location at the front and rear. The lower links are arranged so that the wheels have a negative camber when the springs compress and when cornering at speed. This ensures the best possible contact with the road in any situation. At the same time, the axle technology prevents the front of the car from diving when braking heavily and the rear from squatting when accelerating.

As on the Coupé, aluminium was the material of choice for the new Mercedes-Benz SLR McLaren Roadster's suspension. The wishbones are made from forged aluminium, while the wheel carriers are cast in aluminium. In addition to a whole host of other advantages over conventional steel designs, the lightweight nature of the material allows the suspension to react significantly faster and more sensitively.

The relatively long wheelbase of 2700 millimetres also contributes to the SLR Roadster's exemplary handling and is most evident in the car's exceptional directional stability. Meanwhile, the large track width combined with the low centre of gravity enables high cornering speeds.

Combined spring/damper units at the front and rear axle and an anti-roll bar at the front round off the suspension concept. The anti-roll bar is positioned above the front axle and is controlled via rocker arms, as in a Formula 1 car. This means that it does not take up any installation space which could disrupt the smooth line of the underbody – a vital factor when it comes to the sports car's outstanding aerodynamic properties.

The speed-sensitive rack-and-pinion power steering also fits in with the intelligent lightweight concept. In comparison with other steering systems, this design is characterised by a significantly lower weight. Thanks to its low installed position in front of the engine and its ratio of 12.6, the steering system responds directly to the driver's commands and executes them with supreme precision. The three-spoke steering wheel has a diameter of 380 millimetres and is fitted with an electric motor which allows it to be positioned to suit the individual driver. It can be adjusted by 60 millimetres for reach, and its height can be varied by 2.7 degrees.

Ceramic brake discs for high-endurance performance

The exceptional properties of the electrohydraulic brake system in the Mercedes-Benz SLR McLaren Roadster are complemented to perfection by the brake discs made from fibre-reinforced ceramic that can be found at both the front and rear wheels. Their development is based on the one hand on the results of DaimlerChrysler materials research and, on the other, on the experience with high-tech brakes that Mercedes-AMG has amassed in touring car and GT racing. Here, Mercedes-Benz yet again underlines its leading role in the development of groundbreaking technologies for automotive production.

In manufacturing the brake discs, the carbon fibres, powdered carbon and resin are pressed into shape at high pressure and autoclaved with a silicon infiltration at temperatures of around 1500 degrees Celsius to form the ceramic. The benefits of this composite material are considerable: in addition to their extremely sensitive response, the Mercedes-Benz SLR McLaren Roadster's brake discs are able to withstand temperatures of up to 1000 degrees Celsius which results in tremendous fade resistance when braking from high speed, all while producing as much as 2000 hp of braking power.

Further advantages of the revolutionary new brake material include

- the long life of the brake discs – up to 300,000 kilometres

- the low maintenance requirements of the corrosion-free brake discs

- up to 60 percent less weight than conventional brake discs – a further bonus in terms of dynamic handling and ride comfort

- even more comfortable braking – the low thermal expansion of the ceramic discs means reduced thermal judder under high loads. Similarly, the cold judder familiar from cast-iron brake discs also lessens significantly with ceramic brakes.

Brake pad area of 472 sq. cm at the front axle

The design of the callipers was specially adapted to the fibre-reinforced ceramic brake discs. To this end, Mercedes-Benz developed eight-piston fixed brake callipers which give the front axle excellent stopping power. Special channels, which actively feed cooling air to the outside of the brake callipers, ensure optimum cooling of the brakes.

In the Mercedes-Benz SLR McLaren Roadster there is a total brake pad area of 472 square centimetres at the front axle alone – an exemplary figure which, in combination with the extremely robust high-tech material the brake discs are made from, allows a maximum rate of deceleration of up to 1.3 g.

Pop-up rear spoiler - the airbrake

The outstanding performance of the SLR is also aided by the extending spoiler in the boot lid that is referred to as the "airbrake". If the driver steps heavily on the brake pedal, the rear spoiler rises to an angle of 65 degrees to increase the contact pressure and, as a consequence, the braking forces that can be exerted at the wheels. When braking from high speeds, it lends the SLR outstanding stability, while the noticeable increase in aerodynamic drag boosts the braking effect even further.

Sporty handling dynamics combined with reassuring active safety

The electrohydraulic brake system in the SLR Roadster processes a raft of sensor data describing the current driving status, and uses this to instantaneously calculate and meter the optimum brake pressure for each wheel. A high-pressure reservoir holds the brake fluid, which flows into the system at a pressure of 140 to 160 bar. This also enhances the operation of the Electronic Stability Programme (ESP®), which keeps the SLR safely on track by applying targeted brake pulses to the individual wheels and/or reducing the engine torque. Thanks to even faster and even more precisely metered brake pulses from the high-pressure reservoir, ESP® can stabilise a swerving vehicle smoothly and at an early stage. It was therefore possible to permit a very sporty driving style with controlled side-slip angles in keeping with the character of the high-performance car, but without compromising active safety in any way.

On top of this, the electrohydraulic brake system gives a significant boost to active safety in critical situations too:

Emergency braking: the system interprets the driver's sudden switch from the accelerator to the brake as an indication of an emergency situation and is able to react automatically. With the aid of the high-pressure reservoir, the system increases the pressure in the brake lines and brings the brake pads into contact with the brake discs, so that they can grip with full force the moment the driver steps on the brake.

In the wet: brief, regular applications of the brakes wipe away the film of water that forms on the brake discs so that the brakes can always operate to full effect. This automatic drying function is activated whenever the windscreen wipers have been operating for a certain length of time. The finely metered brake pulses are imperceptible to the driver.

Braking on bends: thanks to variable brake force distribution, the brake system is able to exert an active influence over the sports car's self-steering characteristics. Rather than always applying the brake pressure to the wheels on the inside and the outside of the bend in the same ratio, as with conventional brake systems, distribution of the braking forces is adapted to the situation. The system automatically increases the brake pressure at the wheels on the outside of the bend because, due to the higher wheel contact forces, these wheels are able to transmit greater braking forces. At the same time, the braking forces at the wheels on the inside of the bend are reduced, benefiting the cornering forces which are so important to directional stability. The result is more stable braking behaviour and excellent deceleration figures.

The electrohydraulic brake system also offers special additional functions for even greater safety and comfort:

- The Soft-Stop function allows drivers to draw to a particularly gentle stop, which will be appreciated above all in city traffic involving frequent stops at traffic lights. This is made possible by finely metered pressure control. The Soft-Stop function is permanently activated; a rapid build-up of stopping power is only ever given priority by the system in response to emergency or full brake applications, or when travelling at manoeuvring speeds.

- Start-Off Assist prevents the car from unintentionally creeping forwards or rolling backwards on hills and steep gradients. Brief but firm pressure on the brake pedal is all it takes to activate this function.

- Tailback Assist can be activated using the cruise control lever when the vehicle is at a standstill or when coasting at speeds of up to 15 km/h. The advantage of this function is that in stop-start traffic the driver only needs to use the accelerator; when the accelerator is released, the system brakes the SLR to a halt at a constant rate of deceleration. Tailback Assist can remain active up to a speed of 60 km/h. It is automatically deactivated at higher speeds.

18-inch wheels as standard

Attractive 18-inch alloy wheels are included in the standard specification for the Mercedes-Benz SLR McLaren Roadster. These sporty, 10-spoke wheels are shod with tyres of different widths at the front and rear. 19-inch turbine-design wheels, which emphasise the dynamic character of the Gran Turismo to particularly stunning effect, are available as an optional extra.

An electronic control system monitors the air pressure in the Roadster's tyres. Its sensors are situated in the tyre valves and measure both the air pressure and air temperature inside the tyre. Since it is not possible to install cable connections to the wheels, the information is transmitted by radio. Each sensor sends its data readings about once a minute to special antennae in the wheel arches which relay the information to a control unit. Individual signal identifiers allow this unit to distinguish between the signals from the four wheels, and thereby provide the driver with exact information on the air pressure in each tyre in the cockpit's central display.