Opel presents a range of especially economical and low-emission vehicles at the IAA in Frankfurt (September 13 – 23, 2007). The current models showcase how automotive technology will look in the near future: the Corsa Hybrid concept car uses innovative technology with starter generator and stop/start automatic transmission which contributes to an average consumption of about 3,75 liters of diesel per 100 km (99 g CO2/km). The Vectra Flexpower with a 2.0-liter turbo engine designed for operation with bioethanol/gasoline mix also makes its debut at the IAA.

2008 Opel Corsa Hybrid

- Make: Array

- Model: 2008 Opel Corsa Hybrid

- [do not use] Vehicle Model: Array

Opel will soon offer new ecoFLEX variants, which have the lowest CO2 emissions in their respective model line. The premiere variant – the 55 kW/75 hp Corsa 1.3 CDTI ecoFLEX with diesel particulate filter – makes its European premiere at the IAA. Available to order from December, the well-equipped five-door version produces just 119 grams of CO2 per kilometer, which corresponds to an MVEG consumption of 4.5 liters of diesel per 100 km. ecoFLEX variants of other high-volume model lines will also be available at the end of the year: Meriva 1.3 CDTI ecoFLEX, Astra 1.3 CDTI ecoFLEX, as well as natural gas-powered Zafira and Combo CNG ecoFLEX versions.

The current product portfolio highlights just how committed Opel is to the reduction of emissions and consumption. Numerous Opel models positioned around the ecoFLEX area at the IAA produce less than 140 g CO2 per kilometer.

Corsa Hybrid concept car with just 99 grams CO2 per kilometer

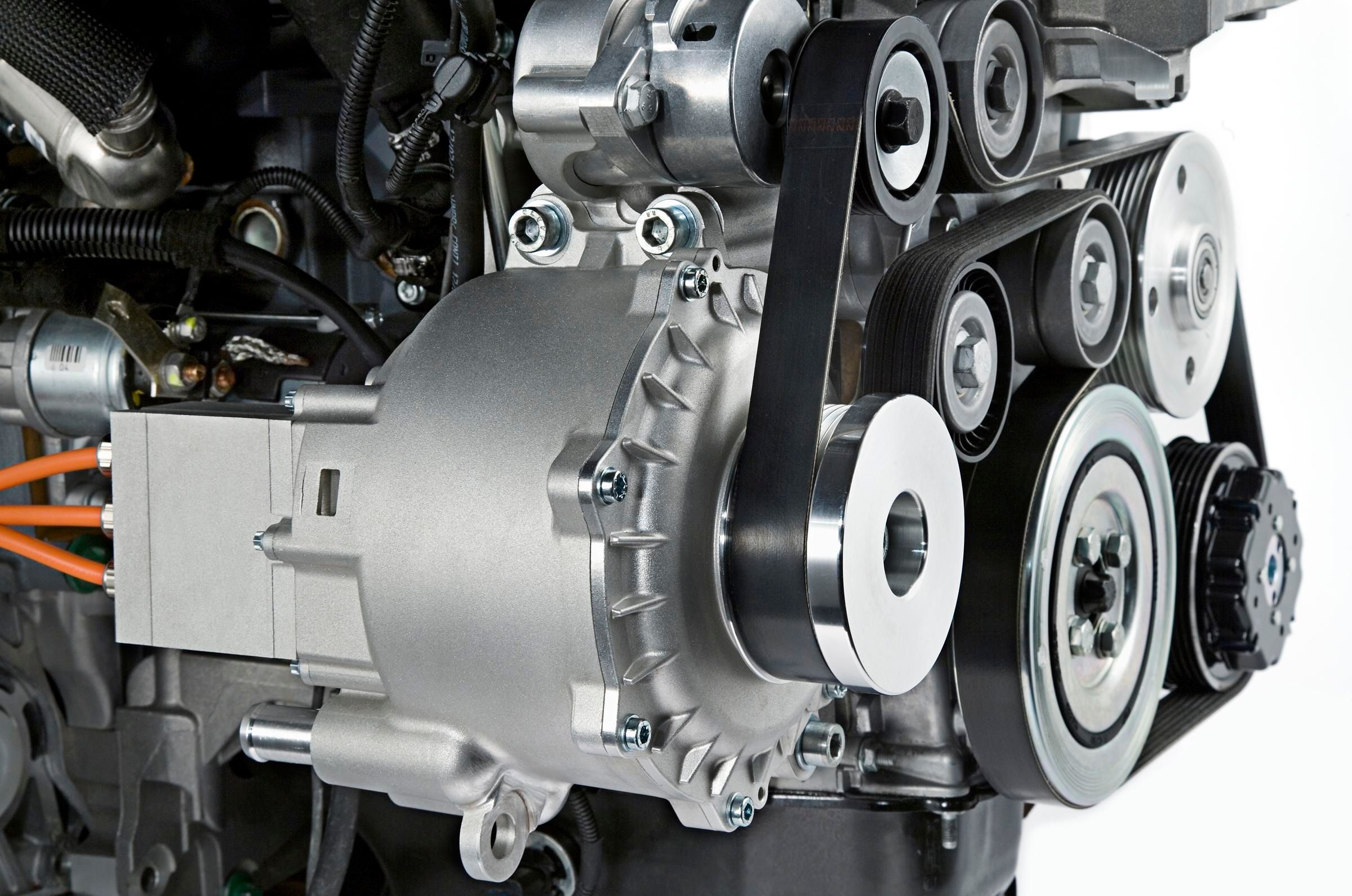

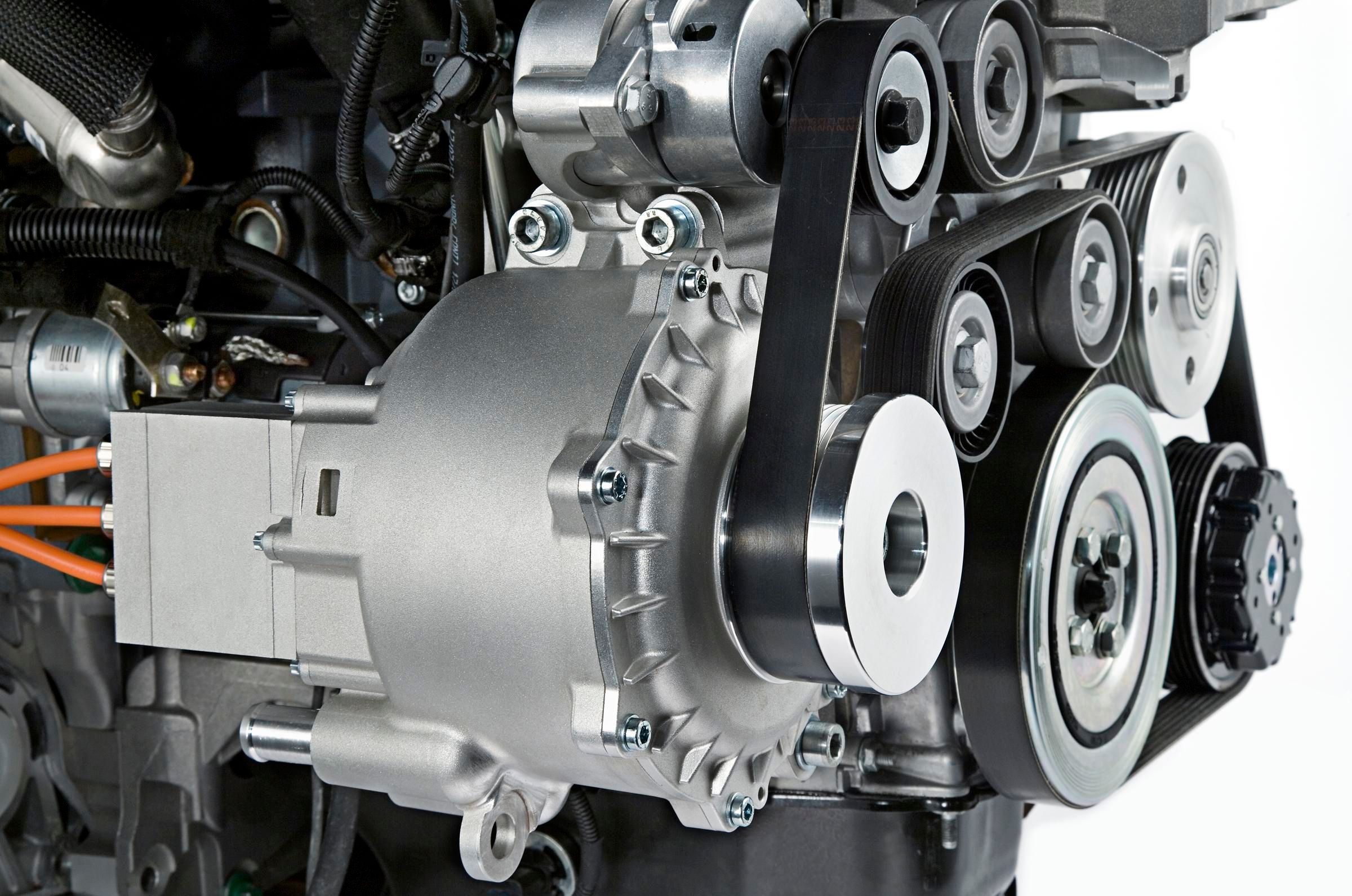

The Opel Corsa Hybrid concept car, which makes its world debut next month at the IAA in Frankfurt, is a result of General Motors’ expanded efforts to reduce fuel consumption and emissions. Powered by the next-generation GM Hybrid system and diesel engine technology, the Corsa Hybrid concept car requires just 3,75 liters of diesel per 100 km and emits only 99 grams of CO2 per kilometer. Based on the 55 kW/75 hp Corsa 1.3 CDTI, fuel savings are largely achieved by GM’s next-generation belt-alternator starter technology debuting in this concept. The Corsa Hybrid uses a lithium-ion battery.  The Corsa Hybrid concept car’s hybrid technology combines the functions of a starter motor and electric generator. Its highly efficient diesel engine is also switched off by the hybrid system when the car is stopped, and restarted when the brake pedal is released. When extra power is required, such as when accelerating or overtaking, the motor provides significantly higher torque. This combination of 1.3-liter diesel engine and electric generator reduces fuel consumption and CO2 emissions. The lithium-ion battery provides the necessary electrical power for the belt-alternator starter, and the battery itself is recharged by the concept car’s regenerative braking function: when decelerating, the fuel is shut off and the vehicle’s kinetic energy is transformed into electrical energy.

The Corsa Hybrid concept car’s hybrid technology combines the functions of a starter motor and electric generator. Its highly efficient diesel engine is also switched off by the hybrid system when the car is stopped, and restarted when the brake pedal is released. When extra power is required, such as when accelerating or overtaking, the motor provides significantly higher torque. This combination of 1.3-liter diesel engine and electric generator reduces fuel consumption and CO2 emissions. The lithium-ion battery provides the necessary electrical power for the belt-alternator starter, and the battery itself is recharged by the concept car’s regenerative braking function: when decelerating, the fuel is shut off and the vehicle’s kinetic energy is transformed into electrical energy.

The Corsa Hybrid concept car represents GM’s global commitment to a comprehensive and cost-effective advanced technology strategy focused on producing commercially viable and sustainable cars and trucks. These include alternative fuel vehicles, ongoing improvements to conventional internal combustion engines and transmissions,

hybrid-electric and electric vehicles, as well as hydrogen fuel cell vehicles.

Corsa 1.3 CDTI ecoFLEX signals the start

At the IAA in Frankfurt, Opel begins the current phase of its long-term ecoFLEX environmental strategy. This includes offering an especially low carbon dioxide-emitting ecoFLEX variant in each high-volume model line. ecoFLEX versions combine low consumption and emissions with excellent economy and driving fun. The first car in this range is the Corsa 1.3 CDTI ecoFLEX, which only produces 119 grams of CO2 per kilometer and consumes an average of just 4.5 liters of diesel per 100 kilometers.

These excellent figures are a result of the world’s smallest four-cylinder common-rail

turbo-diesel engine. The 1.3 CDTI ECOTEC was named “Engine of the Year” in the 1.0 to 1.4-liter displacement class in 2004 by automotive journalists from 26 countries because of its refinement, responsiveness and superb economy. Optimization of the engine map helps the four-cylinder unit achieve an average consumption reduction. High-level fuel management is ensured by the up to five, 1400-bar fuel injection processes per cycle that create an extremely fine fuel atomization in the combustion chambers, which have a total displacement of 1248 cm3. The maximum torque of 170 Nm is available from

1750 - 2500 rpm and maximum output of 55 kW/75 hp at 4000 rpm. The Corsa ecoFLEX with additionally longer axle-drive ratio has a top speed of 163 km/h and accelerates from zero to 100 km/h in 14.5 seconds. This extremely economical engine predestines the Corsa, highly versatile Meriva and spacious Astra five-door model to be ecoFLEX variants.

Natural gas propulsion with monovalentplus concept qualifies for ecoFLEX league

Opel’s natural gas-powered ecoFLEX vehicles also boast impressive environmental qualities. The Zafira and Combo CNG (Compressed Natural Gas) produce almost no soot particles, 20 percent less carbon dioxide than a comparable gasoline model and an up to 80 percent reduction in other harmful emissions. The two CNG variants’ unrivaled low operating costs also qualify them for the ecoFLEX league. The 69 kW/94 hp 1.6-liter engine obtains the most from its fuel, regardless of whether it runs on natural gas, biogas or any mixture of the two. A 14-liter reserve gasoline tank ensures continued mobility on routes without a natural gas filling station. Thanks to economical consumption and ample natural gas tank capacities, a total operating range of over 500 kilometers is available.

The natural gas vehicles’ excellent efficiency and unrestricted everyday suitability is ensured by the innovative monovalentplus concept. This concept made Opel the first automaker to successfully optimize an engine for natural gas operation and still enable the use of conventional gasoline. The unit has special pistons, valves and valve-seat inserts, as well as separate injection banks for natural gas and gasoline.

ecoFLEX variants show their colors

Opel emphasizes the special importance of the ecoFLEX versions with functional and design refinements. The hallmark of the premiere vehicles in Frankfurt is the “Green spirit” exterior lacquer. The bright turquoise color also trims the seat center strips. Distinctive elements of all ecoFLEX variants include the ecoFLEX signet on the rear and the green segment on the rpm counter. The latter shows the ideal rpm range to get the most from the engine’s high fuel-saving potential. The driver then knows when to change gears for improved fuel economy. Green stitching on the leather steering wheel, gear stick sleeve and the green gearshift guide on the gear stick are all eye-catching details.

Portfolio-wide application of environmental technologies

In addition to the ecoFLEX variants, Opel offers a wide range of vehicles that lead the way in their classes for fuel consumption and emissions. The engine concept is called

“Eco-Turbo” and forms the basis for Opel’s state-of-the-art diesel and gasoline engines. Eco-Turbo engines follow the downsizing principle – turbocharged units with relatively small cylinder volumes – and successively replace units with larger displacements. Reduced engine friction and higher thermal efficiency are the results. Eco-Turbo engines run at more economical operating points, which significantly reduce fuel consumption and CO2 emissions. Take the Astra as an example: the 1.6 turbo ECOTEC (132 kW/180 hp) replaced the 2.0 turbo (125 kW/170 hp) in spring 2007. The smaller engine uses 14 percent less fuel than the two-liter unit, and therefore also produces less CO2 emissions. The new 1.7 CDTI turbo-diesel (81 kW/110 hp and 92 kW/125 hp) consumes seven percent less fuel than the 1.9-liter unit (74 kW/100 hp and 88 kW/120 hp). These Eco-Turbo engines also achieve better driving performances.

Gasoline engines with large displacements are being successively replaced by units with gasoline direct injection. Opel’s current direct injection engine range consists of a

2.2 DIRECT ECOTEC and a 2.0 turbo ECOTEC high-tech unit. The 2.0-liter turbo engine from the Opel GT produces an impressive power output per liter of 132 hp and features “Cam-Phase” – variable camshaft phasing –, which together with other measures reduce consumption by an extra three percent. Cam-Phase technology is also used in the

1.6 ECOTEC and 1.8 ECOTEC engines in the Astra, Zafira, Vectra and Signum. Opel also wants to reduce CO2 emissions and fuel consumption further with a range of optimizations to the engine’s periphery. This includes introducing Electric Power Steering (EPS) – familiar from the Corsa – across all variants, as it only draws exactly as much energy as it needs from the generator. The variable oil pump operates in a similar way, only moving as much lubricant around the engine as is actually required in the prevailing driving situation. Other fuel-reduction measures include low-resistance tires and detail improvements to the vehicle’s aerodynamics.

Opel also wants to reduce CO2 emissions and fuel consumption further with a range of optimizations to the engine’s periphery. This includes introducing Electric Power Steering (EPS) – familiar from the Corsa – across all variants, as it only draws exactly as much energy as it needs from the generator. The variable oil pump operates in a similar way, only moving as much lubricant around the engine as is actually required in the prevailing driving situation. Other fuel-reduction measures include low-resistance tires and detail improvements to the vehicle’s aerodynamics.

Vectra Flexpower runs on bioenergy

In the mid-term, Opel is committed to offering more variants that can operate on alternative fuels. At this year’s IAA, Opel displays the Flexpower, a Vectra sedan which appears unchanged from the outside, yet has a two-liter turbo engine that can run on E85 bioethanol fuel, conventional gasoline or any mixture of the two. The Flexpower’s engine management adjusts throttle position, air volume, injection and ignition point depending on the fuel mixture. The result of this continuous calibration is reliable, high performance. Despite the differences between gasoline and bioethanol when it comes to knocking resistance and energy density, the Vectra Flexpower’s 2.0t engine produces 129 kW/175 hp and 265 Nm of torque at 2500 rpm.

As bioethanol is produced from renewable crops, the Flexpower’s propulsion delivers a balanced carbon dioxide level. This is because the amount of CO2 released from E85 during combustion is practically identical to the level of carbon dioxide the plants absorbed from the atmosphere through photosynthesis when they were growing.