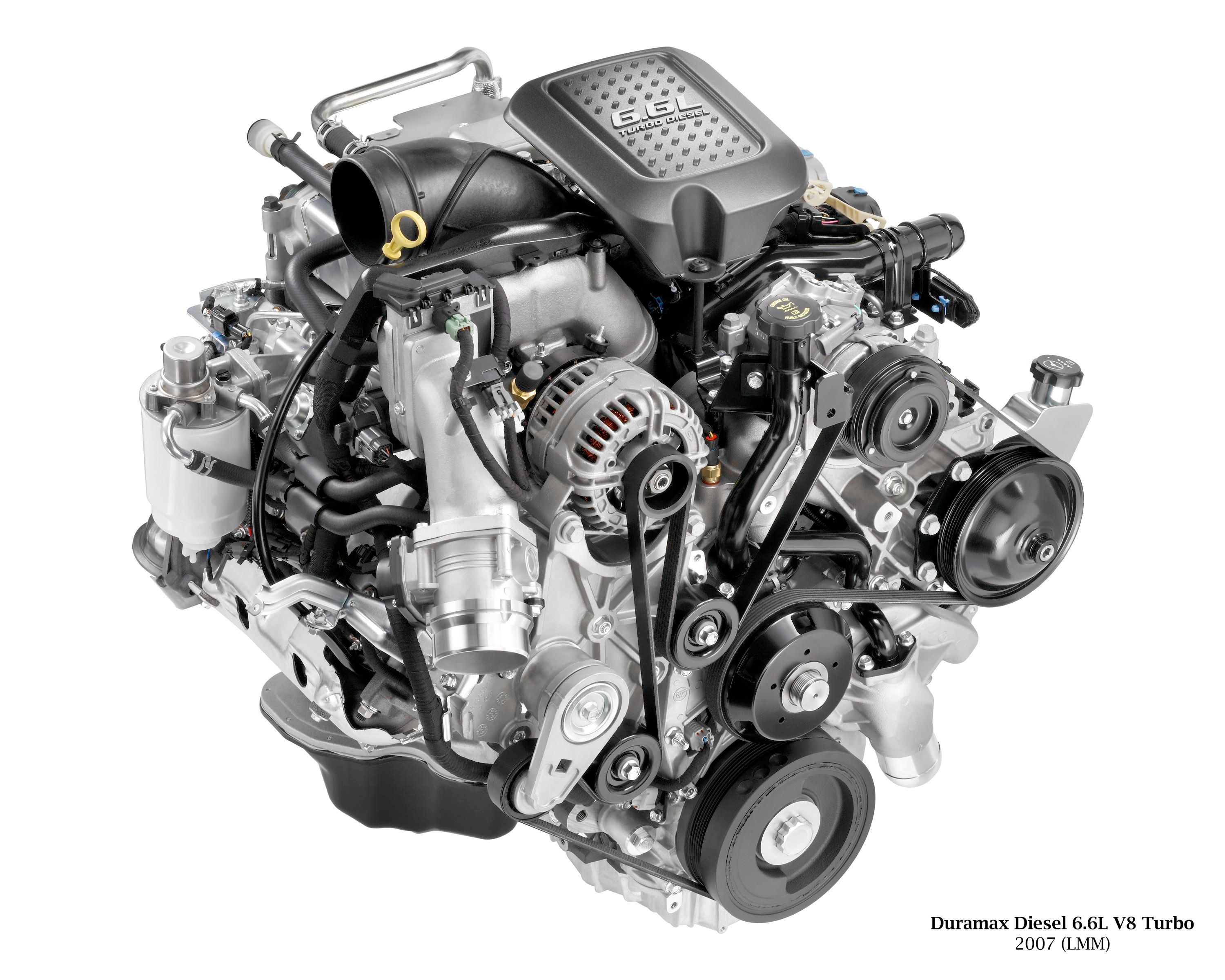

GM Powertrain's powerful Duramax 6.6L V-8 turbo-diesel engine is revised to meet new, stringent 2007 federal emissions regulations and continues to deliver the outstanding power and torque ratings customers expect.

Upgrades to the engine and a new diesel particulate filter system help ensure the engine meets government-mandated emissions regulations for diesel engines manufactured beginning in January 2007, which require a 90-percent reduction in particulate matter and 50-percent reduction in NOx.

"Maintaining power and torque leadership with the Duramax is important to us because it's the benchmark that built the engine's class-leading reputation with our customers," said Charlie Freese, executive director, GM Powertrain Diesel Engineering.

The new Duramax 6.6L V-8 (LMM) engine delivers superior performance ratings. It is offered with increased power and torque for Chevy Kodiak and GMC Topkick medium duty applications. Versions are available with 300 horsepower and 520 lb.-ft. of torque, as well as a new 330-horsepower option with 620 lb.-ft. of torque.

Final advertised ratings for the Chevrolet Silverado and GMC Sierra 2500 and 3500 HD pickups and GM's full-size vans will be released later this year.

The Duramax delivers outstanding acceleration and towing performance. Upgrades implemented in 2006 enhanced the efficiency, smoothness and quietness of the Duramax engine, which was already known as one of the industry's quietest and strongest diesels.

The new emissions standard

The Duramax 6.6L V-8 has new equipment to help it meet the government-mandated 2007 emissions standard. It requires a 90-percent reduction in particulate matter compared with the current standard, which was implemented in 2004, and a 50-percent reduction in NOx.

The use of reformulated, ultra-low sulfur diesel fuel - which goes on sale nationwide this fall - is required to meet the new emissions standard. The new fuel's sulfur content is limited to 15 parts per million (ppm), versus the current standard of 500 ppm. Diesel engines manufactured prior to 2007 can continue to use the current diesel fuel.

To meet the new emissions regulation, the Duramax 6.6L V-8 engine features:

- Additional combustion control, including an even more efficient variable-geometry turbocharging system, cooled (enhanced) Exhaust Gas Recirculation (EGR) and closed crankcase ventilation to reduce NOx

- Additional exhaust control, including oxidizing catalyst and new Diesel Particulate Filter (DPF) to reduce soot and particulate matter

- Increased-capacity cooling system

- New engine control software

- Use of low-ash engine oil

How the DPF works

The 6.6L engine's DPF is based on GM-patented technology and proven supplier components. It traps diesel particulate matter in a honeycomb-like ceramic "brick" after it travels through an oxidizing catalyst. Remaining exhaust gases are routed out through the exhaust system. To ensure optimal performance, the system must undergo periodic "regeneration" to release accumulated soot from the filter. The regeneration process uses heat to burn off the soot and, in most cases, is performed automatically.

An onboard computer controls fuel injection and oxygen content to adjust the exhaust energy to the appropriate level to clean the particulate trap. Periodic servicing of the filter is required to remove accumulated ash. The DPF and corresponding components will change the exhaust system length and/or outlet design, depending on the vehicle model. Also, an expanded underbody heat shield is added. Vocations such as sweepers, airport ground support, municipal and refuse trucks will likely be most affected by the changes.

Duramax 6.6L V-8 details

Revised for 2006, the Duramax diesel uses a variable-geometry turbocharger to optimize boost performance over a wide range of operating conditions. This provides the customer with seamless and immediate response, while simultaneously helping to reduce emissions. The turbo, which spins up to 120,000 rpm, is high-speed-balanced for minimal noise and vibration, while contributing to the engine's overall smoothness and refinement. Maximum boost is 20 psi. Additional details of the Duramax 6.6L V-8 engine's '06 enhancements include:

- Cylinder block casting and machining changes to provide stronger structures with increased reliability and durability

- Upgraded main bearing material increases durability

- Revised piston design lowers compression ratio from 17.5:1 to 16.8:1

- Cylinder heads revised to accommodate higher peak cylinder firing pressure

- Maximum injection pressure increased from 23,000 psi to more than 26,000 psi

- Fuel delivered via higher-pressure pump, fuel rails, distribution lines and all-new, seven-hole fuel injectors

- Improved glow plugs heat up faster through an independent controller

- Revised variable-geometry turbocharger is aerodynamically more efficient to help deliver smooth and immediate response and lower emissions

- Air induction system re-tuned to enhance quietness

- EGR has larger cooler to provide for cooler exhaust gases going into the system

- First application of new, 32-bit E35 controller, which adjusts and compensates for the fuel flow to bolster efficiency and reduce emissions

The engine also features a rigid cast iron cylinder block with induction-hardened cylinder bores; four-bolt, cross-drilled main bearing caps; forged steel, nitride-hardened crankshaft; aluminum pistons with jet-spray oil cooling; aluminum cylinder heads with four valves per cylinder; integrated oil cooler and a charge-cooled turbocharging system. Features, such as easy-access fuel filter and timing gears, reduce maintenance time and effort.