According to the National Oceanic and Atmospheric Association, carbon dioxide levels are at an 800,000-year high, but what if we could pluck CO2 particles out of thin air to use as a raw material for a carbon-neutral fuel? It’s not a pipe dream, because it’s exactly what Audi->ke14 is doing at a research facility in Dresden, Germany. Called e-diesel, the fuel is currently being produced (following an incredibly rapid commissioning phase of just four months) and already powering an A8->ke1089 3.0 TDI.

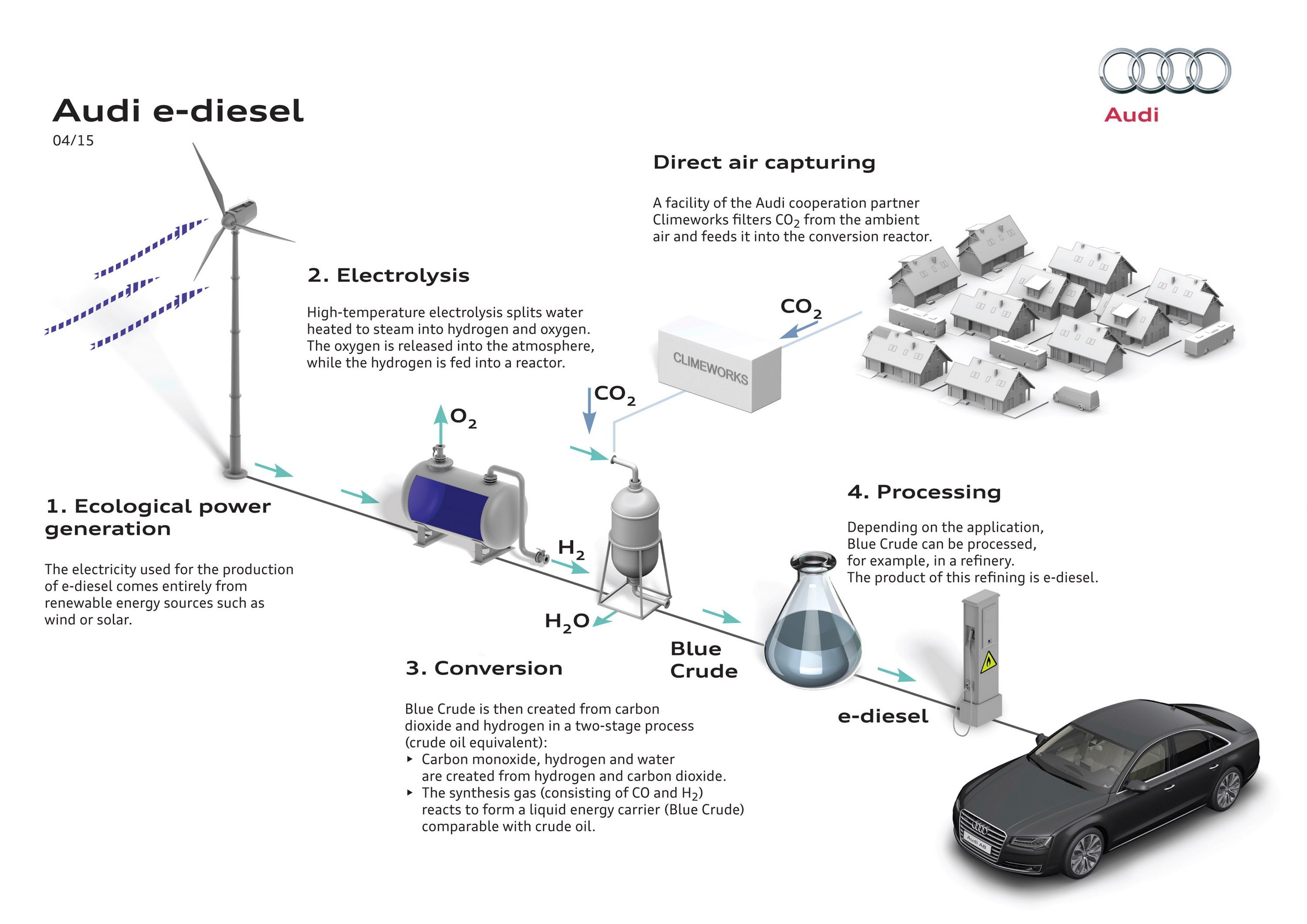

Researched and produced in partnership with Dresden-based energy company Sunfire, the only raw materials needed to make e-diesel are CO2 and water. The method works using the power-to-liquid principle and primarily uses CO2 supplied by a biogas company. The secondary source of CO2 is even more impressive: Another Audi partner, Climeworks in Zurich, has developed a way to capture CO2 particles from ambient air. That means CO2 emitted from e-diesel cars (and anything else that emits CO2, including humans) can potentially be recaptured and reused as fuel, making it a carbon neutral energy source.

Continue reading to learn more about the Audi e-diesel.

Why it matters

Reducing carbon emissions is absolutely essential, but this is something different. If e-diesel technology is taken to its logical conclusion, it means 100 percent of the CO2 emitted from our tailpipes can be reused as fuel — an incredibly obvious solution. Unlike hydrogen and electricity, it also has the added benefits of being compatible with the world’s existing fuel infrastructure and eliminating the need for toxic batteries required by EVs,->ke1030 fuel-cell->ke4483 vehicles and hybrids.->ke147 But these are early days.

The plant at Dresden aims to produce around 800 gallons over the next few months, but with current backing from the German government, the program will likely expand. It’s also possible to mix e-diesel with fossil based diesel, similar to how ethanol and gasoline are mixed to make E85.

Production of e-diesel requires heating water to 800 degrees Celsius to trigger a high-temperature electrolysis that breaks down the steam to hydrogen and oxygen. The hydrogen then reacts with CO2 in synthesis reactor, which results in a hydrocarbon compound, called blue crude. This blue crude is then refined to make e-diesel. It’s an energy-intensive process that Audi says is powered using green energy sources.

To its credit, Audi has been incredibly active when it comes to alternative fuels. The company already has a plant in Werlte, Germany producing a synthetic methane called e-gas, which fuels the A3 Sportback g-tron. Audi’s other e-fuel ventures include a joint project with Global Bioenergies in France to research e-gasoline, and a microorganism-based diesel and ethanol with U.S. company, Joule.

Audi A8

Read our full review here.