Car manufacturers are just like any business - they want to make money. But research and development is a monumental investment for automakers, and that is where companies like ZF come in. ZF (ZF Friedrichshafen AG, or ZF Group) is a manufacturer of car parts that sells components, like its gearboxes, to manufacturers like BMW or Toyota. Now, the company is looking to further its presence by providing entire drivetrains to EV automakers, and the cost savings is likely to drive an entire slew of startup automakers who can bypass expensive R&D costs.

"Plug And Play" Electric Drivetrains Means EV Startups Are Here To Stay

The biggest barrier to companies beginning production of their own cars is the fact that developing and producing an entirely new EV powertrain can be wildly complicated and expensive. Without all the money and some of the best minds in the world, plus a decent amount of good luck, your company is not going anywhere. Faraday and Nikola are prime examples of how an EV startup can fail, even when everything looks promising at the outset. But the next-gen electric drivetrains are so much more efficient, mass-produced, and easy to obtain.

The next wave of EV startups that is surely coming our way will quickly realize that it is easier and cheaper to simply buy an entire drive train from ZF rather than design and build their own from the ground up. This is not bad, if anything it means future EVs are going to be better than they would have been otherwise. We could also see these at use in various forms of motorsport or the aftermarket. If Instagram and SEMA have taught us anything it is that people love shoving an electric powertrain into a vintage or retro muscle car, sports car, or SUV. Perhaps there could be a competitor to Wiesmann's Project Thunderball that could wildly undercut it on price.

Next-Gen Electric Motors Will Be More Powerful, Lighter, And Smaller

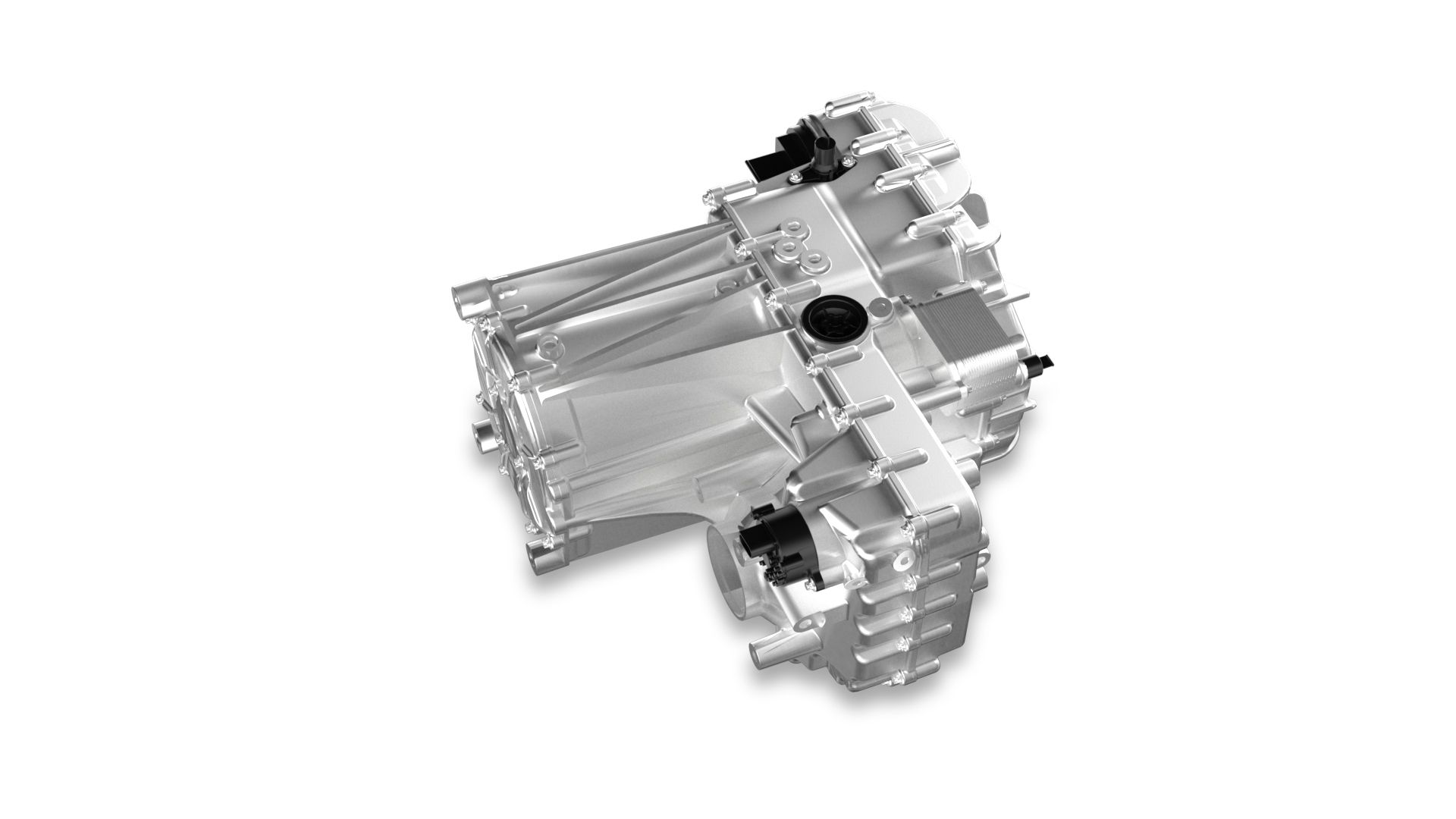

In addition to improving the efficiency of electric motors, ZF is aiming to improve the entire electric powertrain, or what it calls e-drive. That means modifying the motors, gearboxes, power electronics, and converters. Its motor has been upgraded by implementing a new technique for cooling and winding the copper rods. Now oil can flow directly on and around the copper rods, where most of the heat is generated inside the electric motor, which results in more power from the same weight. Plus, not as much rare metal is required in the construction, according to ZF. The company says that the continuous power of the electric motor is increased to up to 85 percent of the peak power. The new "hairpin" winding technique results in a physically smaller package - ZF claims 10% less raw materials are used in its next-gen motors.This could allow for more range from a smaller battery and lower costs. Obtaining money for an EV startup has not seemed extremely difficult, but making that money go a long way is another story.

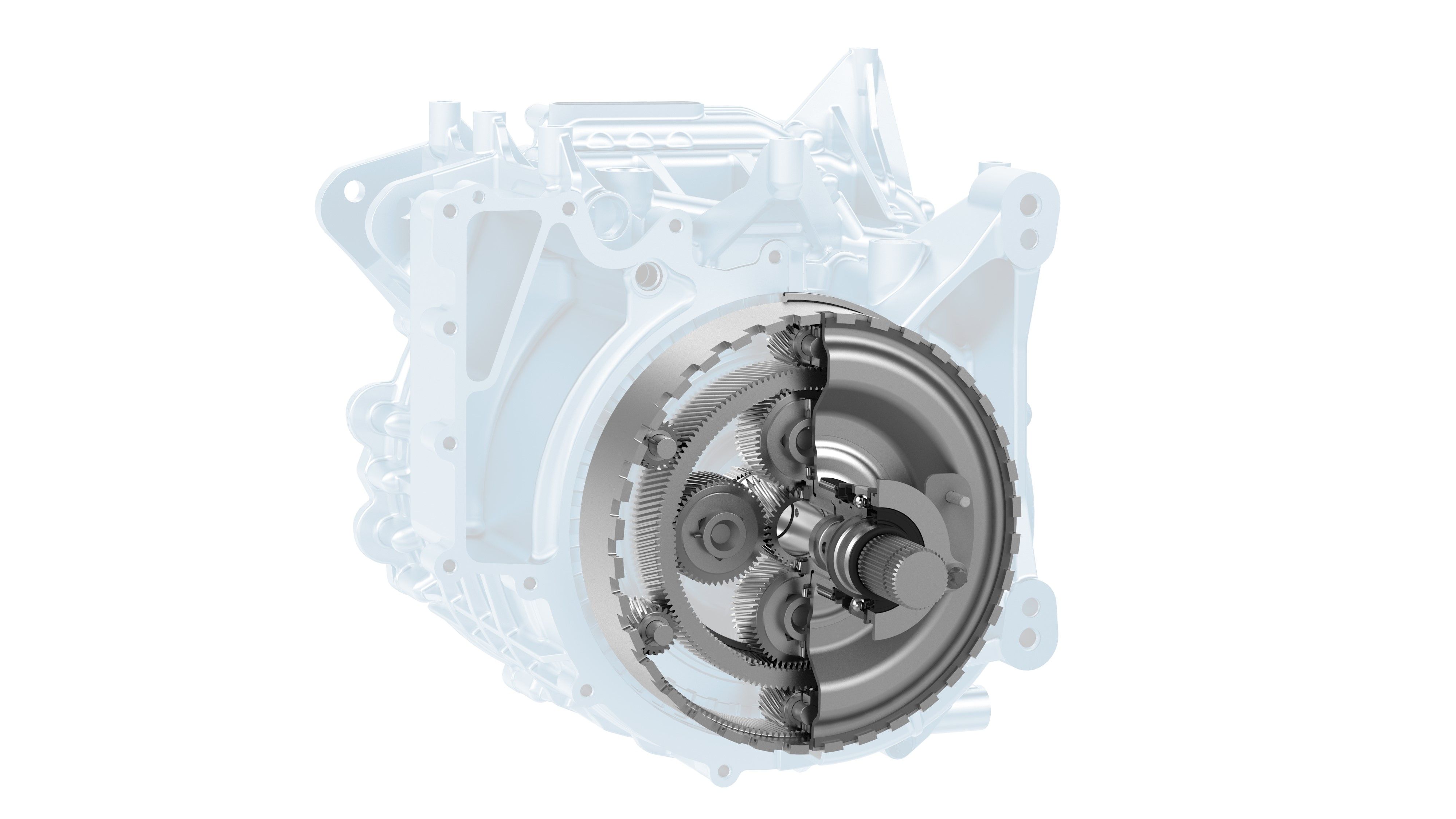

The new gearboxes will feature two integrated planetary gears (like in the Porsche Taycan) and they will handle the job of a transmission and a differential. The final package is smaller and lighter as well. The power electronics will feature new chips which allow for each e-drive unit to be better tailored and programmed to a specific role or market. Lastly, the high-voltage converters, which are used in fuel-cell electric drives, are now 99.6% efficient, ZF reported.

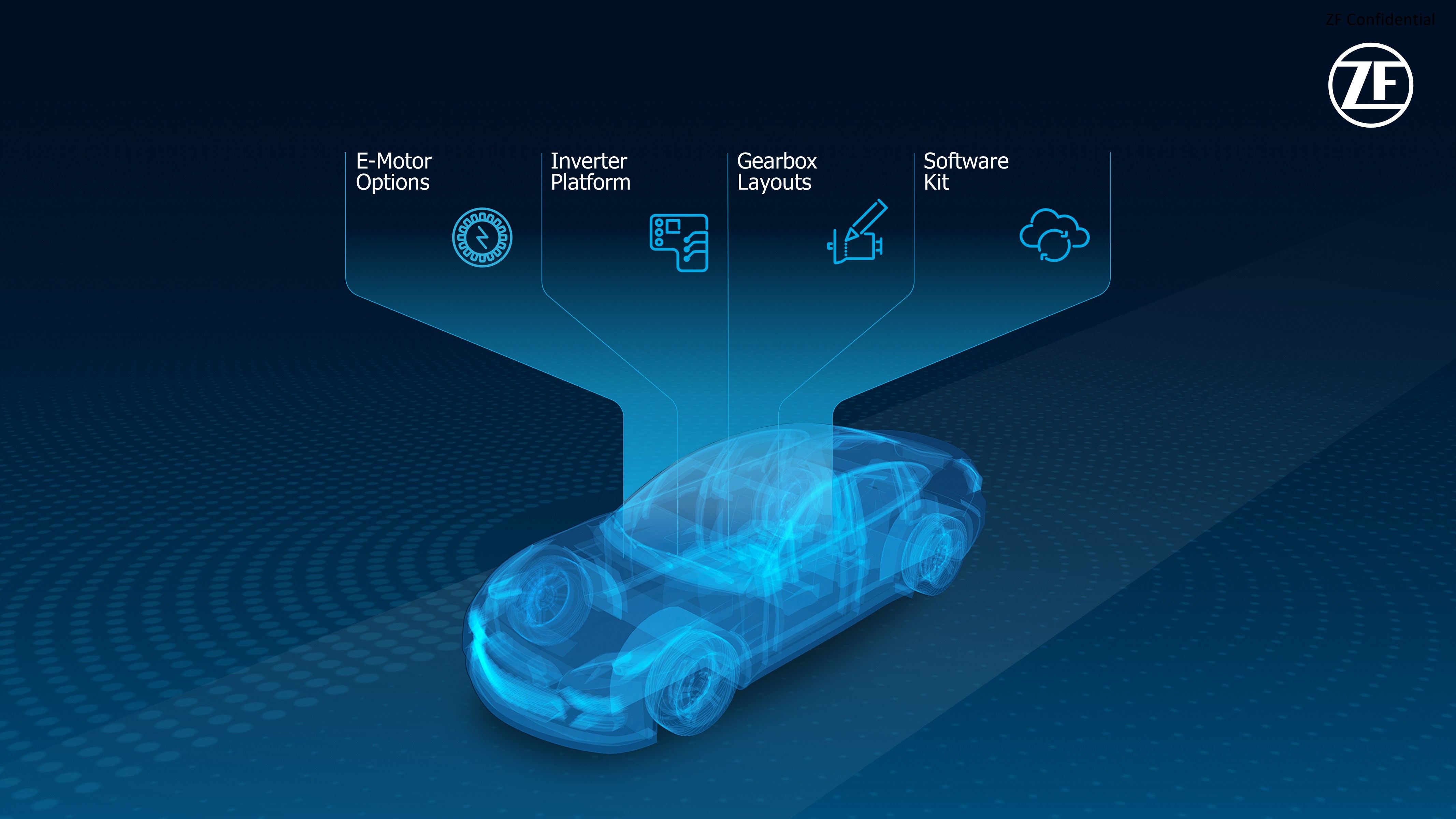

ZF will begin offering the e-drive systems to automakers as a modular system in three configurations beginning in 2025, however, individual components will be available sooner. There are also 400- or 800-volt architectures, permanent-magnet synchronous or asynchronous, and with power outputs ranging from 67 to 738 horsepower. ZF also said in its press release that the backlog of electric motors and other components is worth nearly $26 billion. ZF expects that these e-drive systems can be used in either personal use, such as your car, or commercial use which could range from forklifts to massive semi-trucks or construction vehicles.