Don’t look now, but Michelin isn’t the only tire company that’s on the precipice of a technological breakthrough that could redefine the way the industry uses the wheel. Enter Continental, which is all set to showcase what it calls the dual New Wheel Concept that essentially puts the wheels and the brake disc into one element, thereby eliminating a host of issues that can potentially happen with the current physical makeup of these parts.

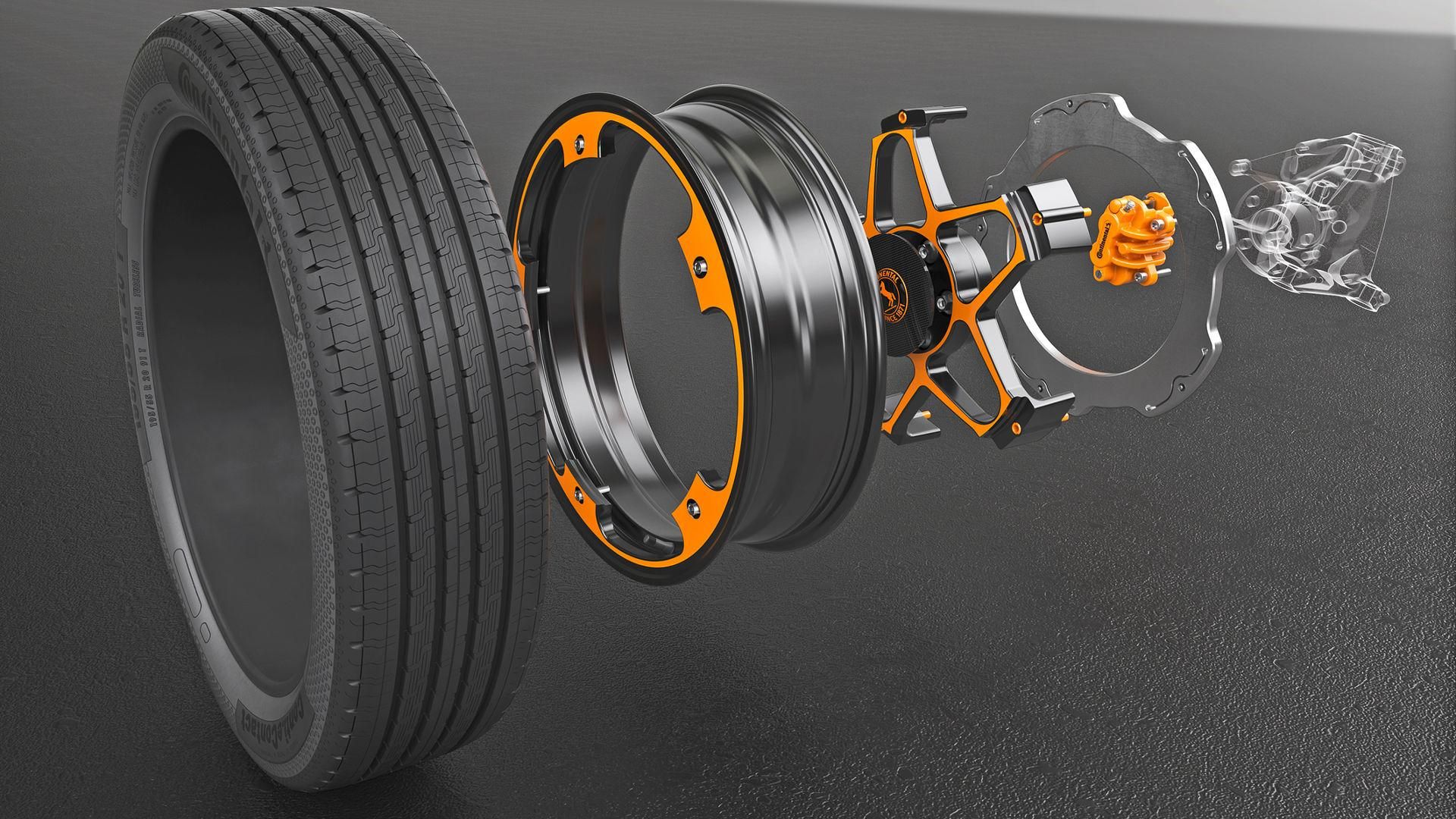

While it’s not as flashy as 3D printing wheels the way Michelin’s envisioning its own future, Continental’s New Wheel Concept is no less intriguing. The specifics of the concept features a new outer section on the wheel called the rim well, and an inner section called the carrier star that itself incorporates an aluminum brake disc. The wheels themselves are largely targeting electric cars, in part because it dramatically reduces the car’s overall weight, which automakers can use on other elements or take what they can get depending on their preferences. More importantly, though, the new wheel concept also improves braking while also eliminating poor braking performance brought about by corrosion. According to Continental, the aluminum disc is designed to last the whole life of the car. The whole idea of a versatile, multi-purpose wheel is intriguing, and if these wheels hold up under stringent testing, Continental could have something here that could put a literal meaning on the phrase “reinventing the wheel.”

Continue after the jump to read the full story.

How does it work and how does it compare to Michelin's own concept?

Diving into the specifics of Continental’s New Wheel Concept reveals how exactly the tire maker developed the technology into what it is today. The first aspect of it is the inner star section, which Continental says attaches to the hub with the wheel brake carefully fastened to the wheel carrier of the axle. In this configuration, the brake engages the disc from the inside, which in turn, allows for a wider friction radius that minimizes the wear and tear while still keeping its efficiency functioning to its fullest capabilities.

According to Continental, only brake pads are subjected to wear as the physical brake components are able to last longer when paired with regenerative braking, which most electric cars have at their disposal. The wheels’ lightweight design also means that it uses less energy to accelerate and maintain the speed the car is going in.

The concept nature of the wheels does mean that it’s still probably some years away from heading into production, if it ever does at all. They’re still being subjected to a lot of testing, as Continental is supposed to do anyway. Hopefully, significant enough progress happens to the point that the concept actually becomes viable for production.

How does it compare to Michelin’s Visionary Concept?

On the surface, the comparison appears to be moot because Michelin’s concept is for a 3D printed tire. But there is more to it than meets the eye with these concepts, particularly that of Michelin's because the concept itself is a combination of a wheel and tire. By virtue of it being 3D printed, any possibility of the tire getting punctured is effectively hurled out the window. In addition, the whole concept is made entirely from 100-percent recyclable materials while also taking the shape of a honeycomb biomimetic structure. In other words, it’s basically an environmentally friendly, 3D-printed wheel and tire concept. How far along the project is to reality is up in the air, but at least there’s been some progress made with regards to the next evolution of wheels and tires.

Continental and Michelin have theirs. What’s the industry going to come up next?

References

Read more about the Michelin Visionary Concept Tire.