British heavy machinery maker, JCB has developed a combustion engine that works on Hydrogen. As with the entire industry, pushing for electric powertrains, JCB too initially jumped on the trend and soon realized that there are some major setbacks with battery technology for their applications. They feel that Hydrogen provides a better way to go green. What does this mean for the combustion engine? Well, Let's find out.

This is a slightly off-beat topic from the stuff that we generally put out here at TopSpeed, but is still relevant because it goes over the future of combustion engine technology. Hydrogen has quickly emerged as a critical component of the current energy revolution, that must attain market readiness as soon as possible. In conventional transportation, it is supplied into a fuel cell, which reverses the electrolysis process to generate energy and power an electric motor.

But can Hydrogen be used with combustion engines? British heavy machinery maker, JCB has come up with a different, potentially easier solution. It might be accomplished faster than the difficult application of electric batteries for big vehicles or the commercialization of expensive fuel cells.

JCB has a long history of experimenting with different powertrains. In 2018, the firm introduced a battery-powered mini-excavator (19C-1E), which is now available in their product portfolio, and since then, it has also marketed electric telescopic handles. For a year, JCB had been testing a fuel cell version of its 220 X model and a 20-ton excavator at its test facility.

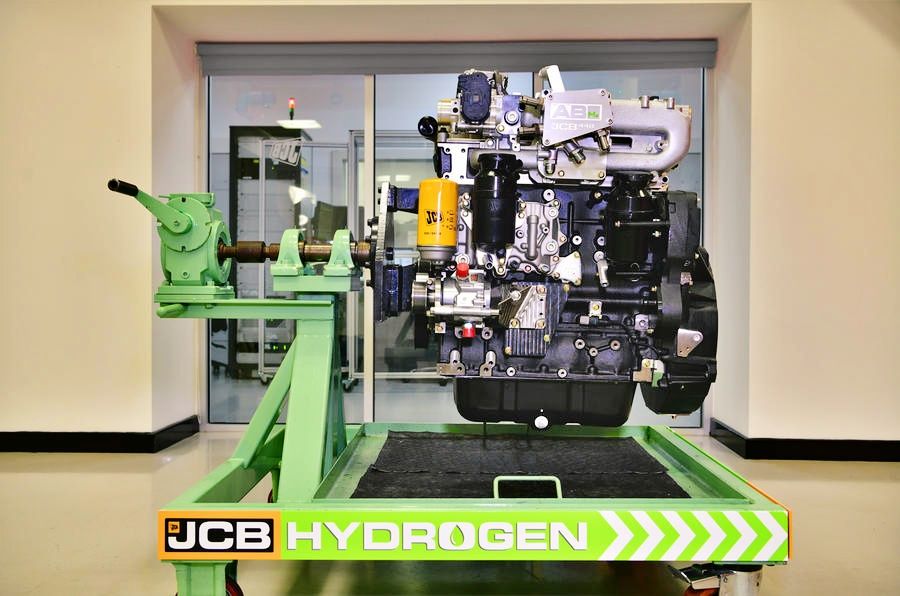

Recently, they developed and unveiled a hydrogen-powered piston engine, based on its years of experience. This Hydrogen piston engine is initially intended for big heavy machinery. The key advantage of hydrogen engines, according to JCB Innovation Chief Tim Burnhope, is that they can be built swiftly and economically while retaining the current ICE know-how and infrastructure. Hence, the manufacturing could make use of pre-existing supply chains. Thus, production may start in just a few years and at a comparatively low cost compared to the alternatives.

The prototype engine from JCB has a whole new guiding system (low compression, new pistons, high-pressure common rail fuel delivery, port injection), but it is meant to match the performance and operational characteristics of existing machines. A new intake system, for example, is one of the most significant changes. Considerable improvements to the top end, on the other hand, not only limit CO2 but also have significant advantages over the relatively expensive battery-powered electric and hydrogen fuel cell options.

Because hydrogen is carbon-free, the combustion from these engines produces no greenhouse emissions. According to JCB, even the trial engine's raw exhaust has fewer nitrogen oxides than even the most powerful JCB diesel engine. The hydrogen engine will run on synthetic gas, primarily green hydrogen, and will be powered by the grid. The power plant is still fairly tiny at 360 kW, but the next step is planned to be a 50-100 megawatt power plant.

Of course, JCB's hydrogen engines are aimed at their own off-highway uses, but following successful early testing on excavators as engines are in far higher demand than cars and trucks, the company's engineers, are aiming for a much broader variety of vehicles. JCB intends to create more hydrogen engines and is currently focusing on ramping up production of this new technology.

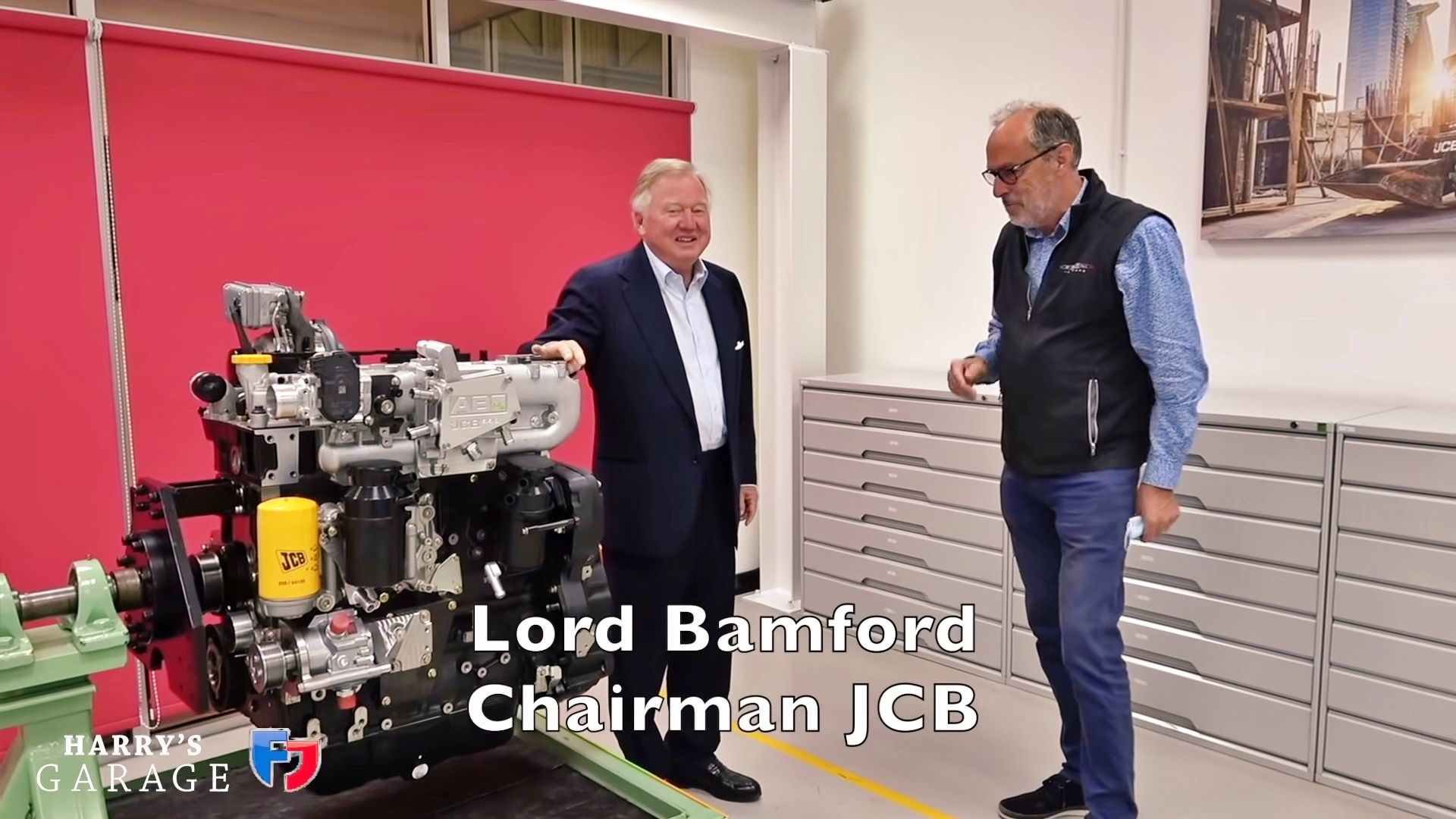

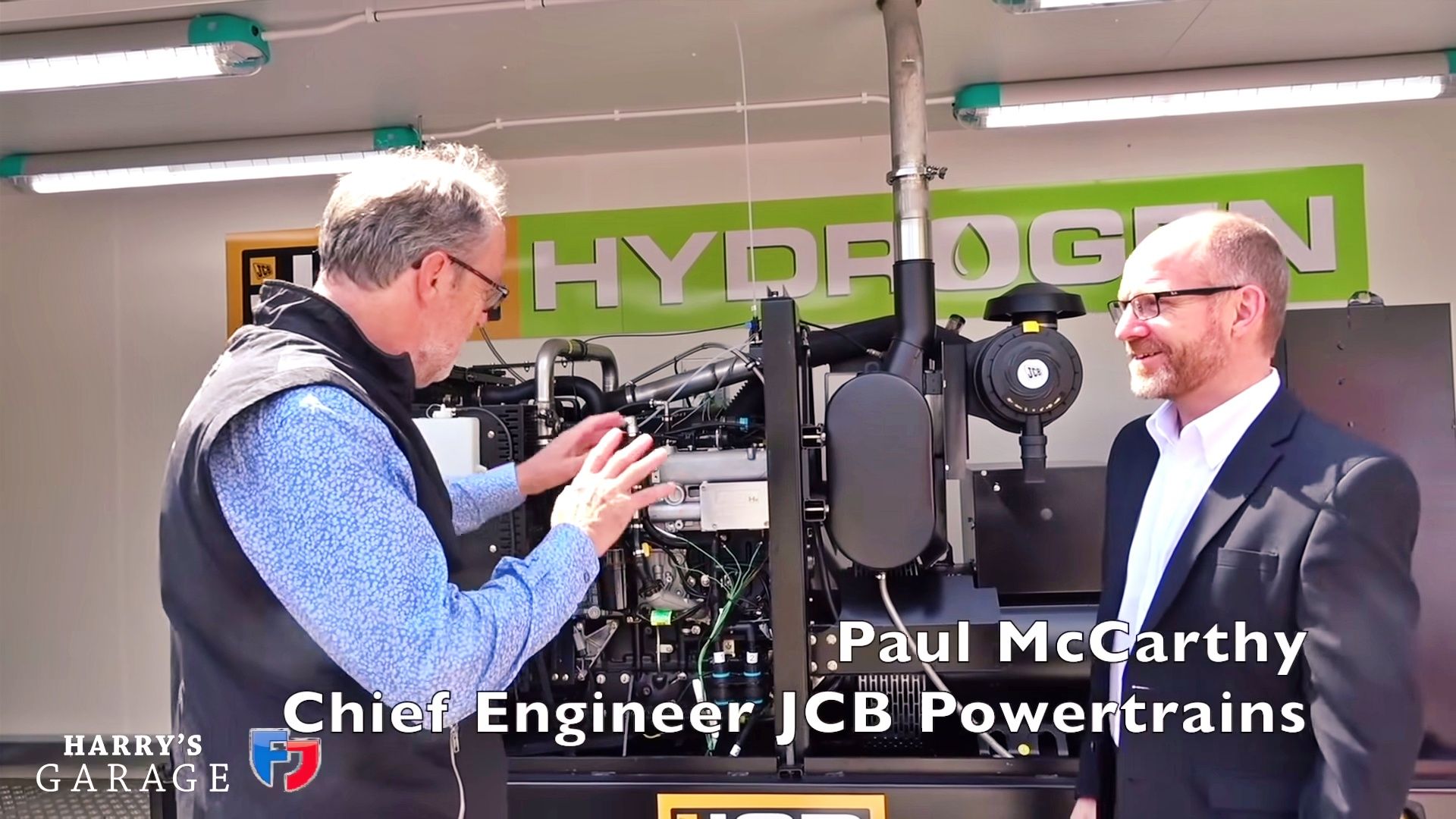

Harry Metcalfe from Harry's Garage got a chance to catch up with Lord Anthony Bamford from JCB, giving us an overview of this innovative Hydrogen Piston engine. Catch the entire video below.