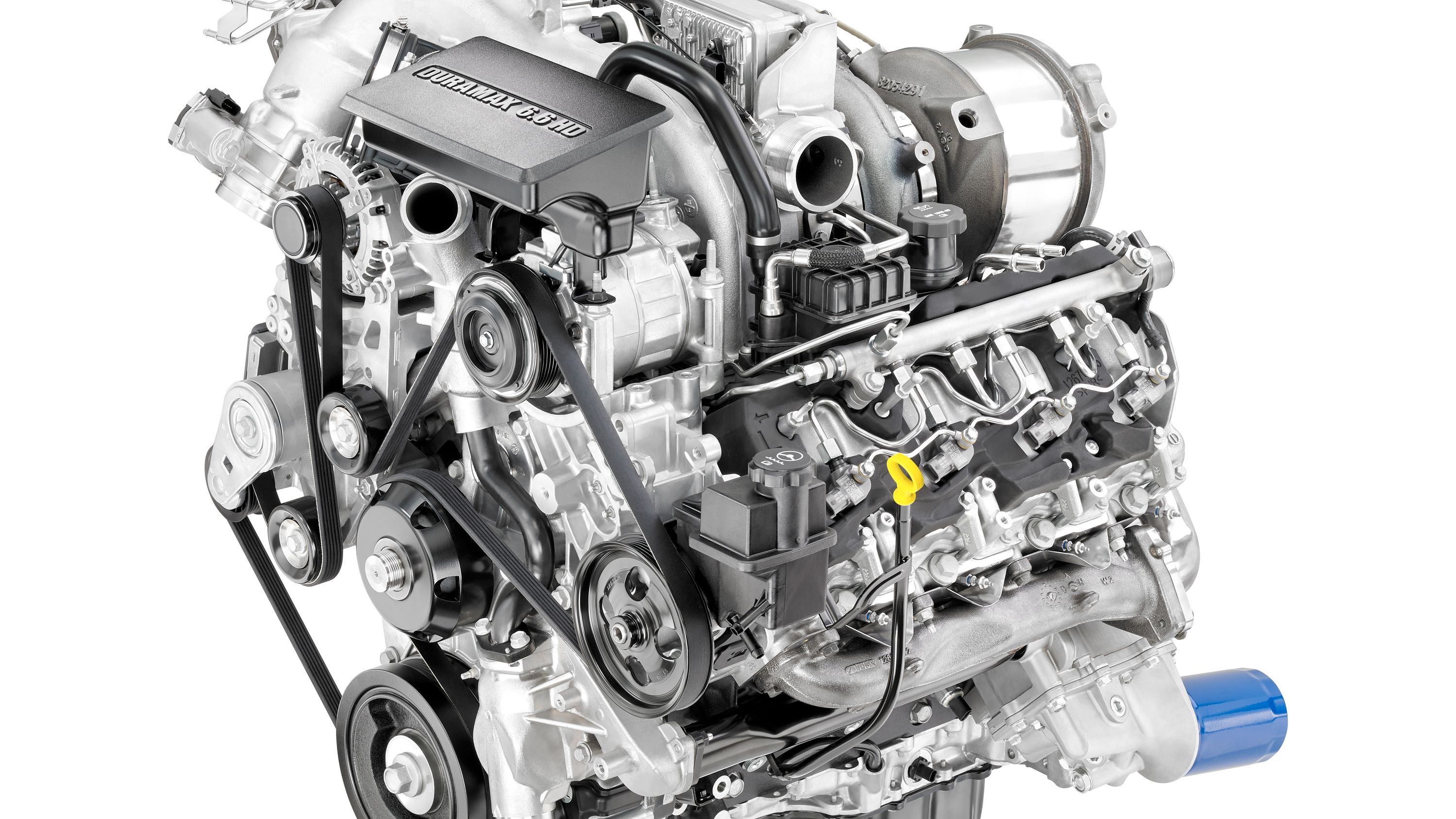

The wait is over and the anticipation is now satisfied – GM has officially debuted its heavily revised 6.6-liter Duramax V-8 turbodiesel. Actually, “heavily revised” might be an understatement. GM says only the stoke and bore remain unchanged over the outgoing LML Duramax, letting the new engine retain the familiar 6.6-liter displacement. Nearly every other component is updated or completely new for the 2017 model year.

The benefit? An increase of 48 horsepower and 145 pound-feet of torque, along with cooler operating temperatures leading to increased durability during sustained high-load events, strong cylinder heads, a stronger main block, increased oil flow capacity, a new electronically actuated and controlled turbocharging system, and an acoustically tuned oil pan and valve covers that dramatically reduce engine noise.

“Nearly everything about the Duramax is new, designed to produce more torque at lower rpm and more confidence when trailering or hauling,” said Gary Arvan, chief engineer for the new Duramax. “You’ll also notice the refinement improvements the moment you start the engine, and appreciate them as you cruise quietly down the highway — with or without a trailer.”

The advancements allow the turbodiesel to generate 90 percent of its peak torque at only 1,550 rpm and maintain it through 2,850 rpm. It’s at 1,600 rpm that all 910 pound-feet is realized. Within that power band at 2,800 rpm, the engine reaches peak its horsepower of 445. This sustained torque curve gives the Duramax a wider power band for hauling and towing. The new torque spec represents a 19-percent increase from the previous engine. Despite the added power, the Duramax is 38 percent quieter at idle.

Continue reading for more information.

More Duramax Details

The 2017 Duramax uses a cast-iron engine block with induction-hardened cylinder walls. Its 4.05-inch bore and 3.89-inch stroke specifications are practically the only aspects retained from the previous-generation Duramax. The engine block features a deep-skirt design for added strength. The cross-drilled main bearing caps are held in place with four bolts. This helps hold the Duramax’s strengthen forged micro-alloy steel crankshaft with larger-diameter connecting rod journals. The bearing areas are also larger, allowing for increased durability against the heightened cylinder loads.

A new oiling system features more flow than before, along with a dedicated feed for the turbocharger and larger piston cooling jets that squirt nearly twice the oil volume at the bottom of the pistons. Helping keep oil temperatures in check is a 50-percent larger oil cooler. A new two-piece oil pan is constructed from aluminum around its upper section and laminated steel around the bottom portion. This not only adds strength, but the laminated steel cuts down on engine noise at idle.

There’s also a new Venturi Jet Drain Oil Separator system. Basically it helps collect the oil mist floating within the crankcase blow-by gas, sending it back into the sump for continued use. This is a first-in-class system, as well.

The Duramax’s pistons are also new, made from cast aluminum. They have a taller crown area and a remelted combustion bowl rim. This remelting thing is basically where the piston head is re-heated after it’s already cast, then the combustion bowl is formed. After that, the piston is sent to the final machining process.

|

|

|

|

Aluminum is also used for the cylinder head. GM says the Duramax was the first turbodiesel in the segment to offer aluminum heads. Six head bolts are present for each cylinder, making the bond between block and head immensely strong. The cam-in-block design operates four valves per cylinder for greater airflow.

The heads also have to contend with 28 psi of boost coming from the variable-geometry turbocharger. The new turbo is electronically actuated in its geometry, providing a range and boost levels throughout its rpm range. The incorporated exhaust brake is also redesigned for 2017, giving the Duramax better control and capacity for engine braking.

Cold mornings won’t be a problem for the Duramax. Its new glow plugs are computer controlled and can heat the combustion chambers in less than three seconds, even when outside temperatures are -20 degrees Fahrenheit. All this without the use of a block heater.

A new EGR system helps cut down on NOx emissions, even before the exhaust gasses reach the aftertreatment system. A propriety heat exchanger cooled the exhaust gasses before they re-enter the combustion chambers, further cooling the intake temperatures and therefore leading for improved performance.

The proliferation of Biodiesel won’t be an issue for the Duramax, either, as it can run B20 Biodiesel.

General Motors will continue using the Allison 1000 six-speed automatic transmission behind the Duramax. The transmission does boast new internal components built to withstand the increased torque load.