Car manufacturers are hard at work, coming up with more efficient powertrains. While electrification seems to be the focal point, there are plenty of companies still developing ways to make the internal combustion engine more efficient. Nissan is among these companies, with its variable compression technology, said to combine the best from gasoline and diesel engines. Here’s how it works and how it’s different from Mazda’s SKYACTIV engines.

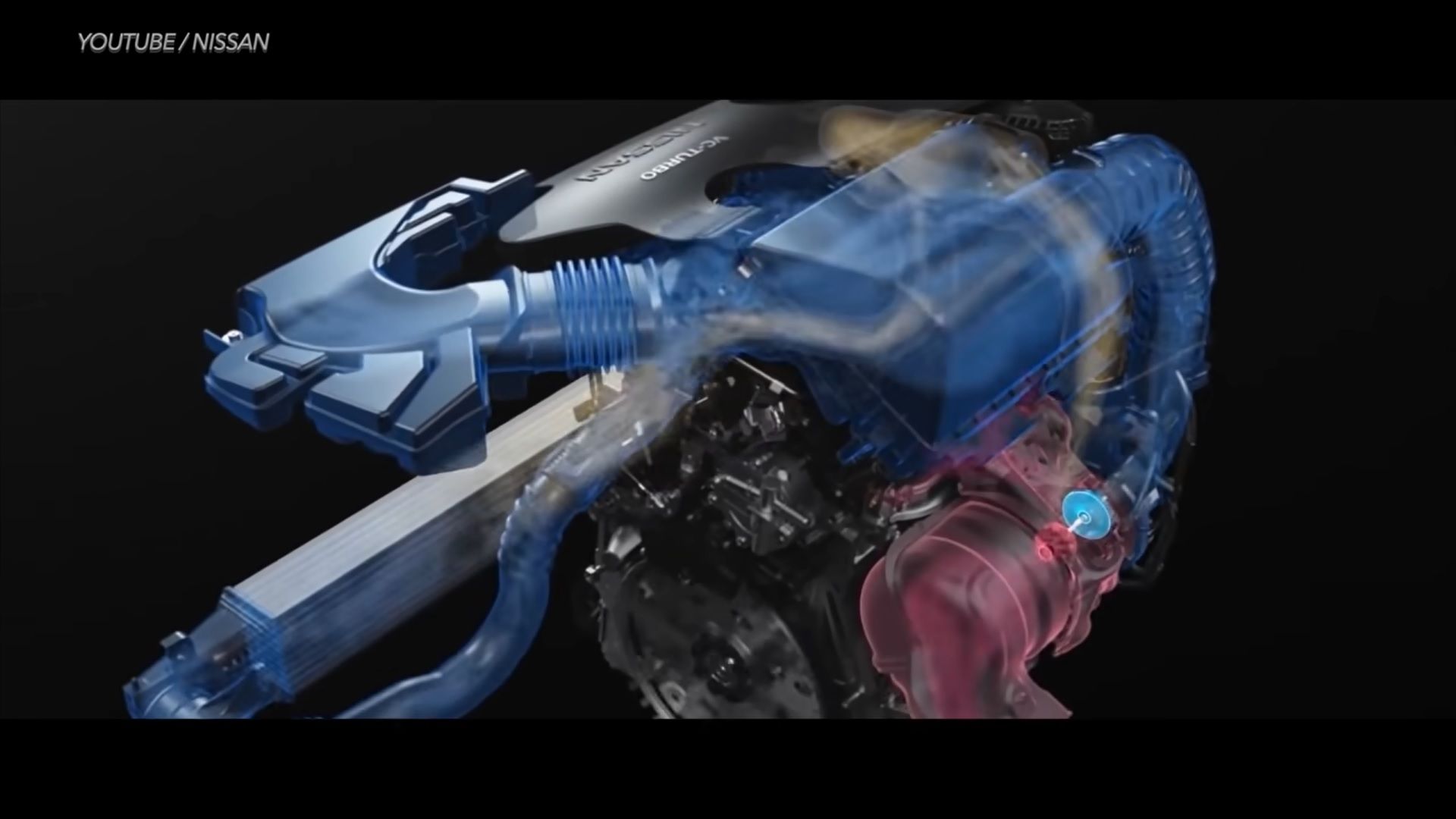

In 2018, Infiniti – Nissan’s luxury brand – unveiled a variable compression engine. The technology was implemented a year later, in 2019, in the Infiniti QX50 and Nissan Altima. The VC Turbo engine combines the efficiency of diesel engines with the performance of gasoline engines.

How does Nissan’s variable compression engine work?

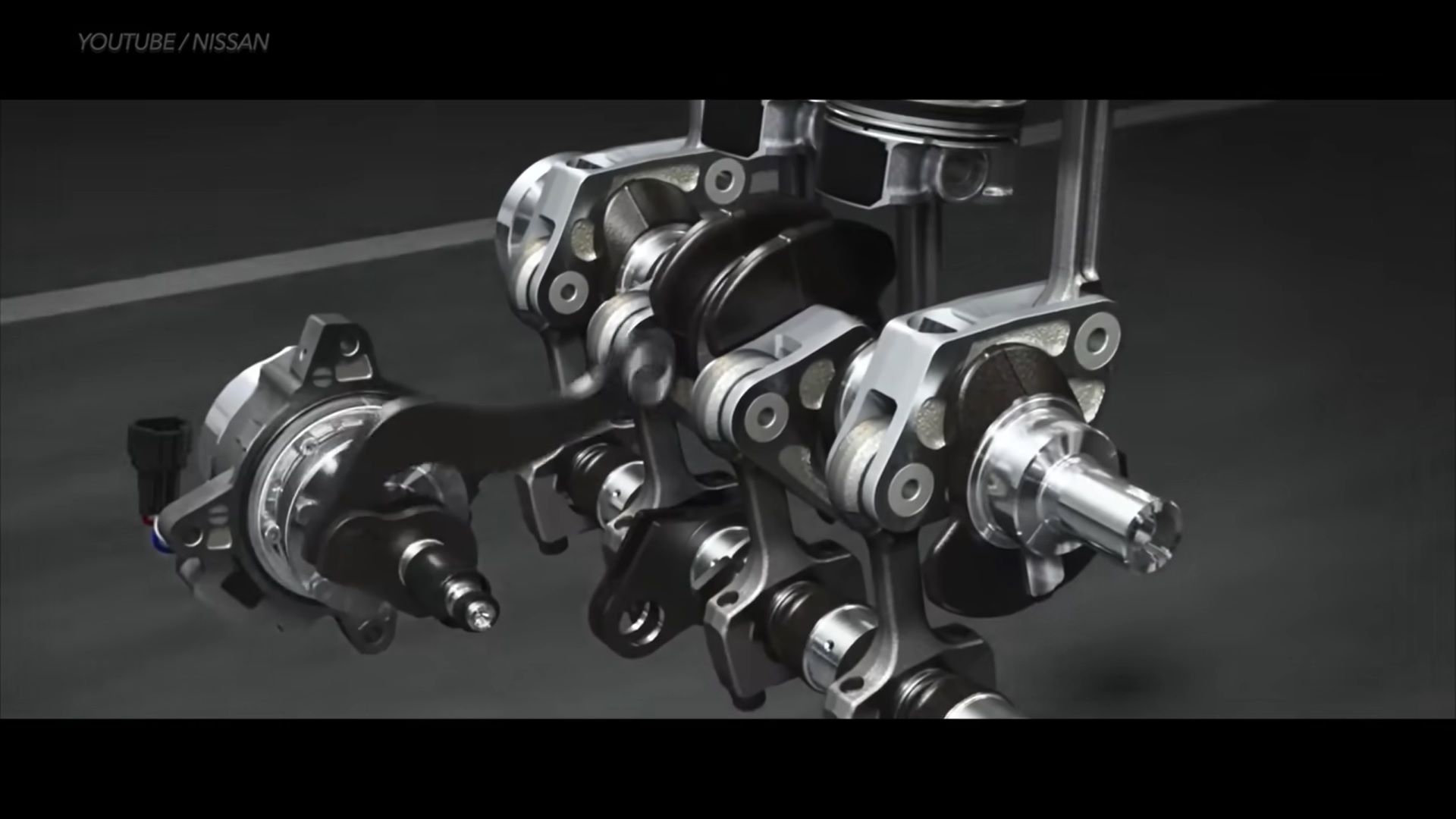

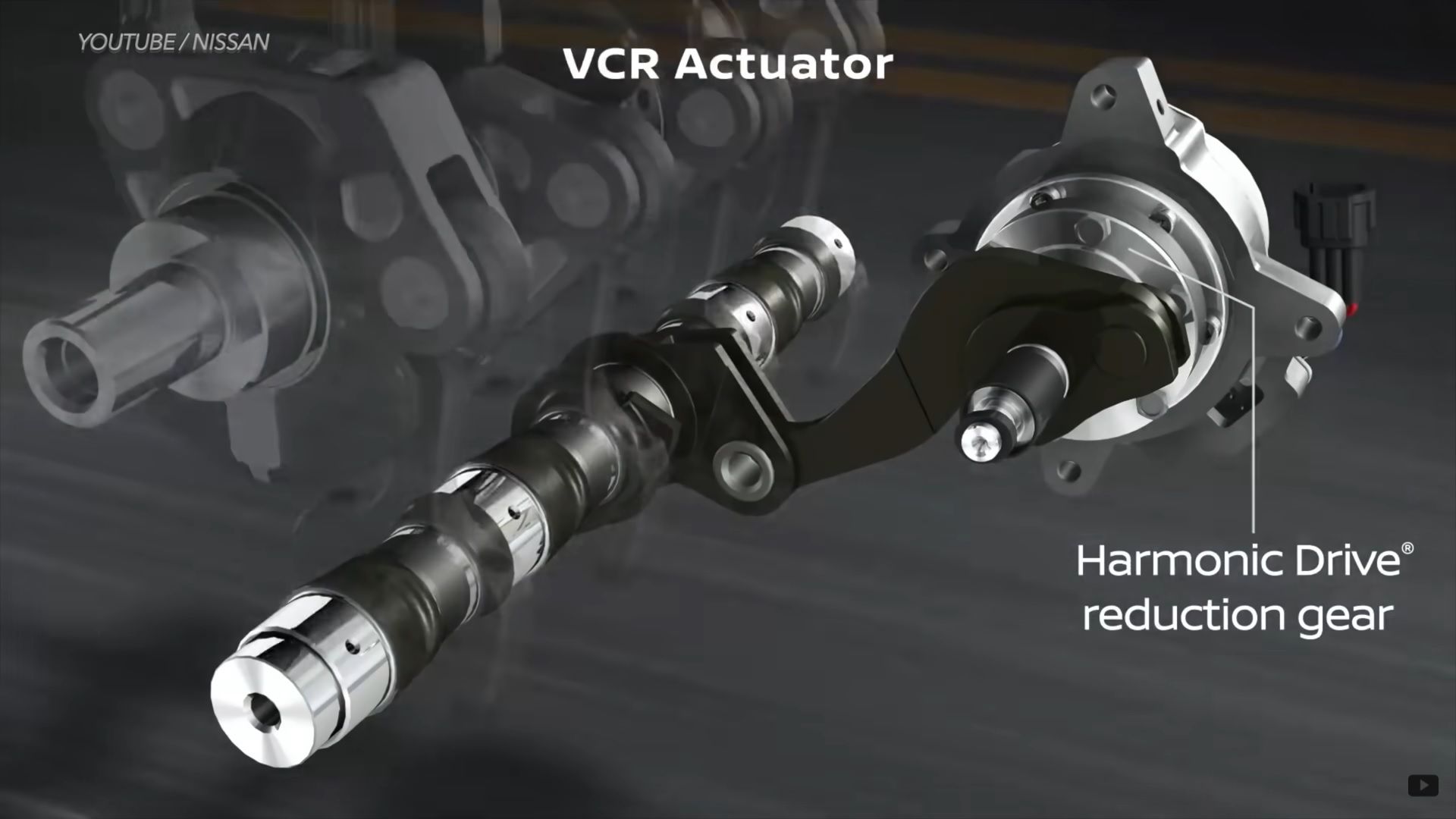

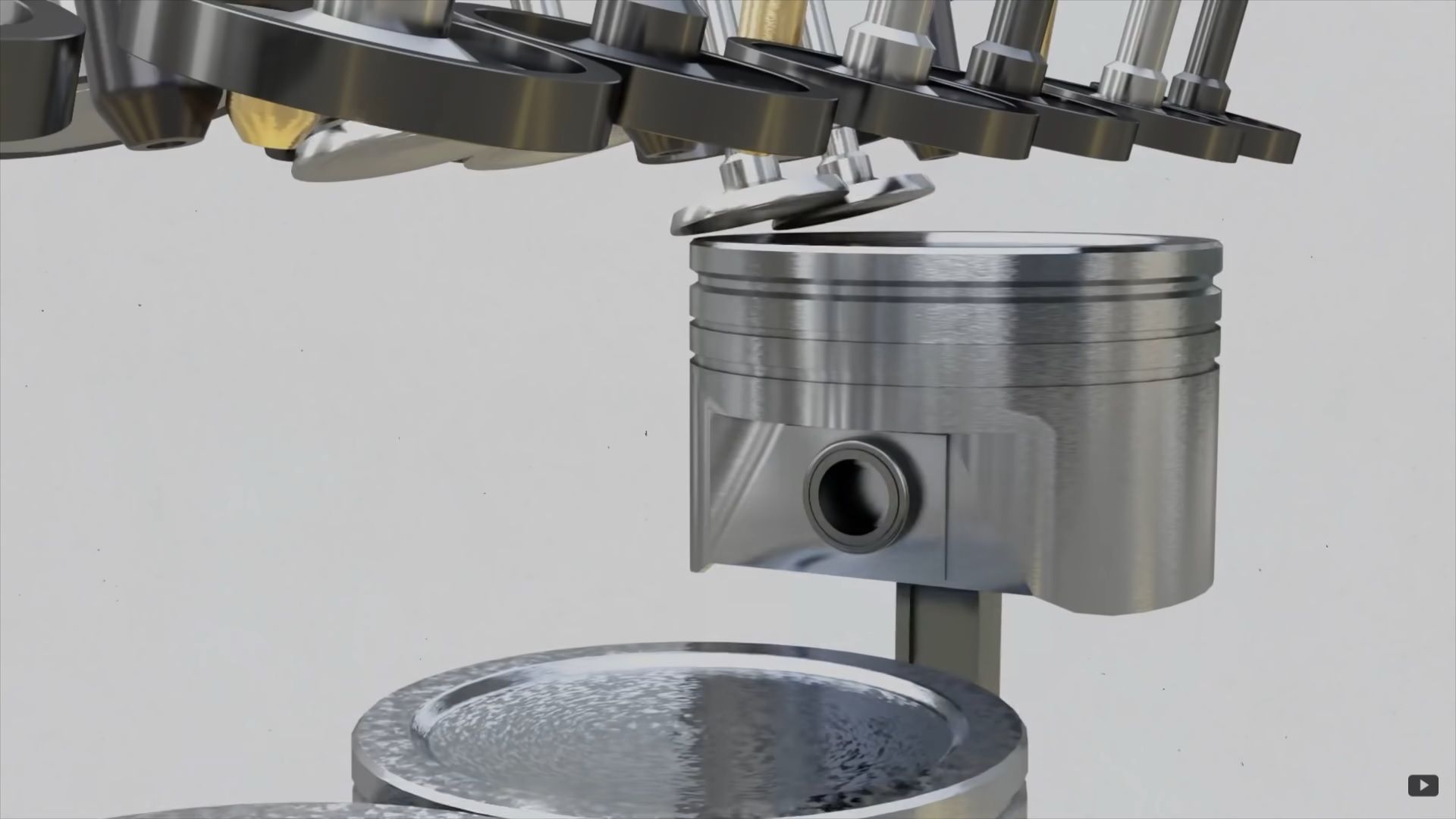

Nissan’s variable compression engines rely on an advanced multi-link system, utilizing a VCR actuator and a harmonic drive reduction gear, which effectively alter the length of the piston stroke, depending on the engine load. The system is able to alter the compression ratio between 14:1 in normal driving and 8:1 under load. In addition to the variable compression, the VC Turbo engine features both direct fuel injection and port fuel injection, allowing it to instantly switch between a conventional cycle and an Atkinson cycle.

This is great because diesel engines are on average 20- to 35-percent more fuel-efficient than an equivalent gasoline engine, under normal driving conditions. This means that Nissan’s variable compression engine can provide great MPG, very similar to a diesel engine while providing the performance of a gasoline engine, with the corresponding high-RPM efficiency, lacking in diesel engines.

A good example is Nissan’s 2.0-liter KR20DDTT engine, which features variable compression technology, packs 248 horsepower at 5,600 RPM and 273 pound-feet (370 Nm) at 4,000 RPM. This is a replacement for the old 3.5-liter naturally-aspirated V-6 engine, which packed 270 horsepower at 6,400 RPM and 252 pound-feet (341 Nm) at 4,400 RPM. More importantly, the 2.0-liter VC Turbo engine is 15-percent more fuel-efficient than the outgoing V-6 and produces fewer emissions.

How does Nissan’s VC Turbo engine compare to Mazda’s SKYACTIV engine?

Mazda SKYACTIV engines have gone a different route, in pursuit of efficiency. The company’s SKYACTIV-X engines rely on spark-controlled compression ignition (SPCCI), which combines the ignition method of gasoline and diesel engines into one, for greater efficiency. Through SPCCI, the spark plug creates a fireball, which results in rapid and simultaneous combustion at multiple points, instead of gradual combustion like in conventional engines. The resulting compression ignition pushes the piston down longer and with more force. The compression ratio, however, does not vary like in Nissan’s VC Turbo engine.

The SKYACTIV engine also utilizes a lean supercharger, which adjusts the inlet air pressure thus leaning out the fuel mixture and adjusting the compression ratio as required. This also prevents knocking and means you don’t necessarily need to use premium fuel. Like the Nissan VC Turbo, Mazda’s SKYACTIV-X also works on a 14:1 compression ratio.

However, it does so in all modes while the Nissan unit alternates between 14:1 compression at low speeds and light loads. Once you step on the throttle, the top-dead-center of the pistons is shifted down, reducing the compression ratio to 8:1.

Nissan variable compression engine drawbacks

While there are no inherent disadvantages to the variable compression engine to speak of, one downside is that the heavy-duty parts needed for the engine’s reliable operation add 22 pounds (10 kg). On the plus side, the VC Turbo engine does not need a balancing shaft in order to offset the weight of the new parts and dynamic engine mounts reduce vibration noises in the cabin to a minimum.

The idea of a variable compression engine is not new

While it was in 2019, we got a variable compression engine in a production car, VC Turbo technology has been in development for 20 years, with over 100 prototypes being developed. However, these prototypes have been used solely for research purposes, concerning the combustion processes. The idea of variable compression internal combustion engine was, actually, born in the 1920s, thanks to a British engineer, Harry Ricardo.

Among his main researches was the issue of uneven combustion, also known as knocking, which led to him creating a variable compression test engine. His work, eventually, led to the development of the fuel octane system. Other projects that spawned from Ricardo’s invention include Continental’s AVCR-1100 variable compression tank engine. In the 1990s, various brands like Daimler, Peugeot, Ford, Volvo, Honda, Porsche, and others were also looking at variable compression engines, but it was Nissan that beat them to a production variant.