Additive manufacturing, known more popularly as 3D printing, is a novel manufacturing technique that’s captured the imagination of the car industry, promising a long list of benefits for both automakers and consumers. But of course, as is the case for any new technology, there are always questions over safety - but rest assured, Bugatti is rigorous when it comes to testing, as evidenced in this four-and-a-half minute video.

Clamping Down On New Tech

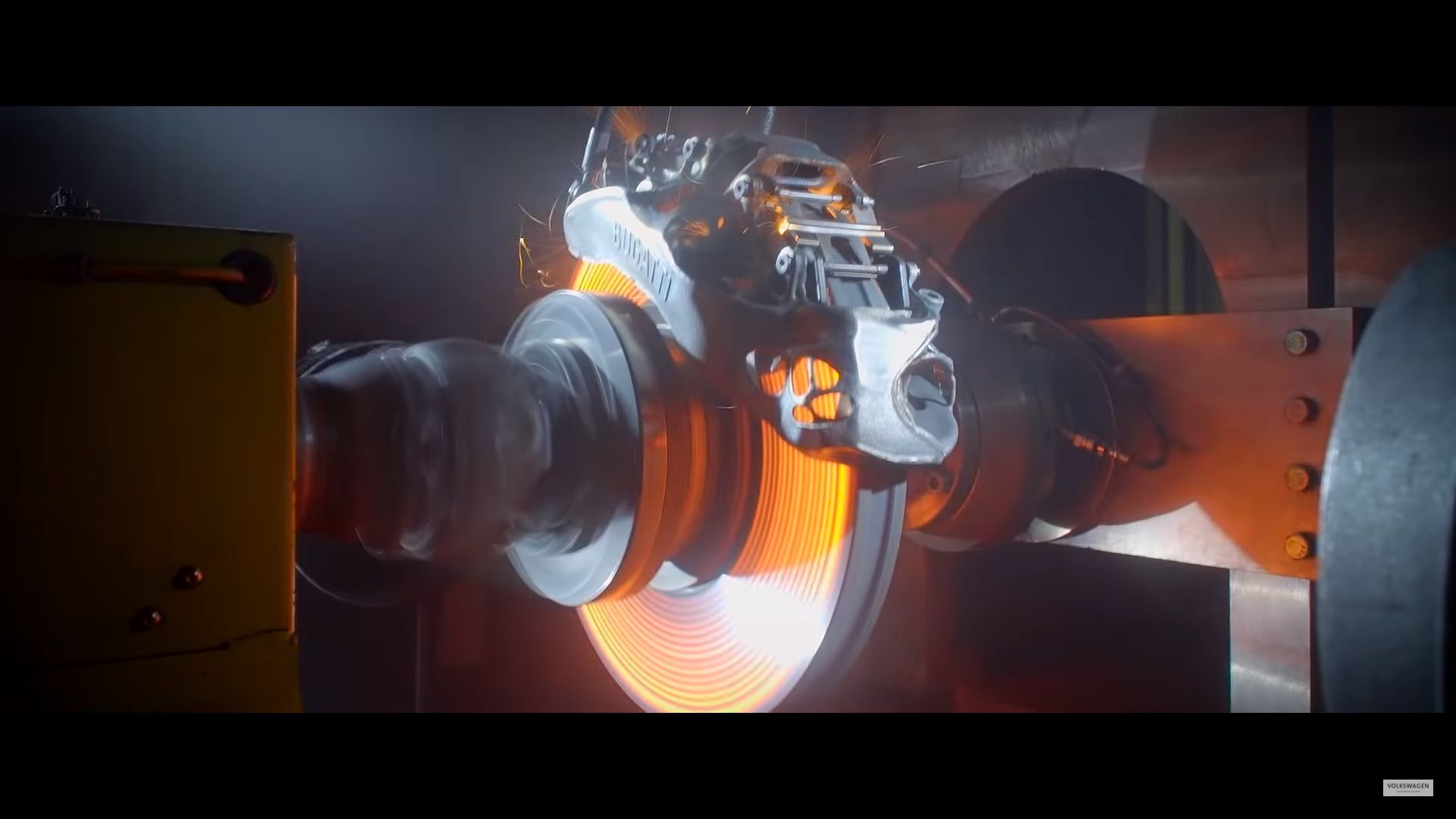

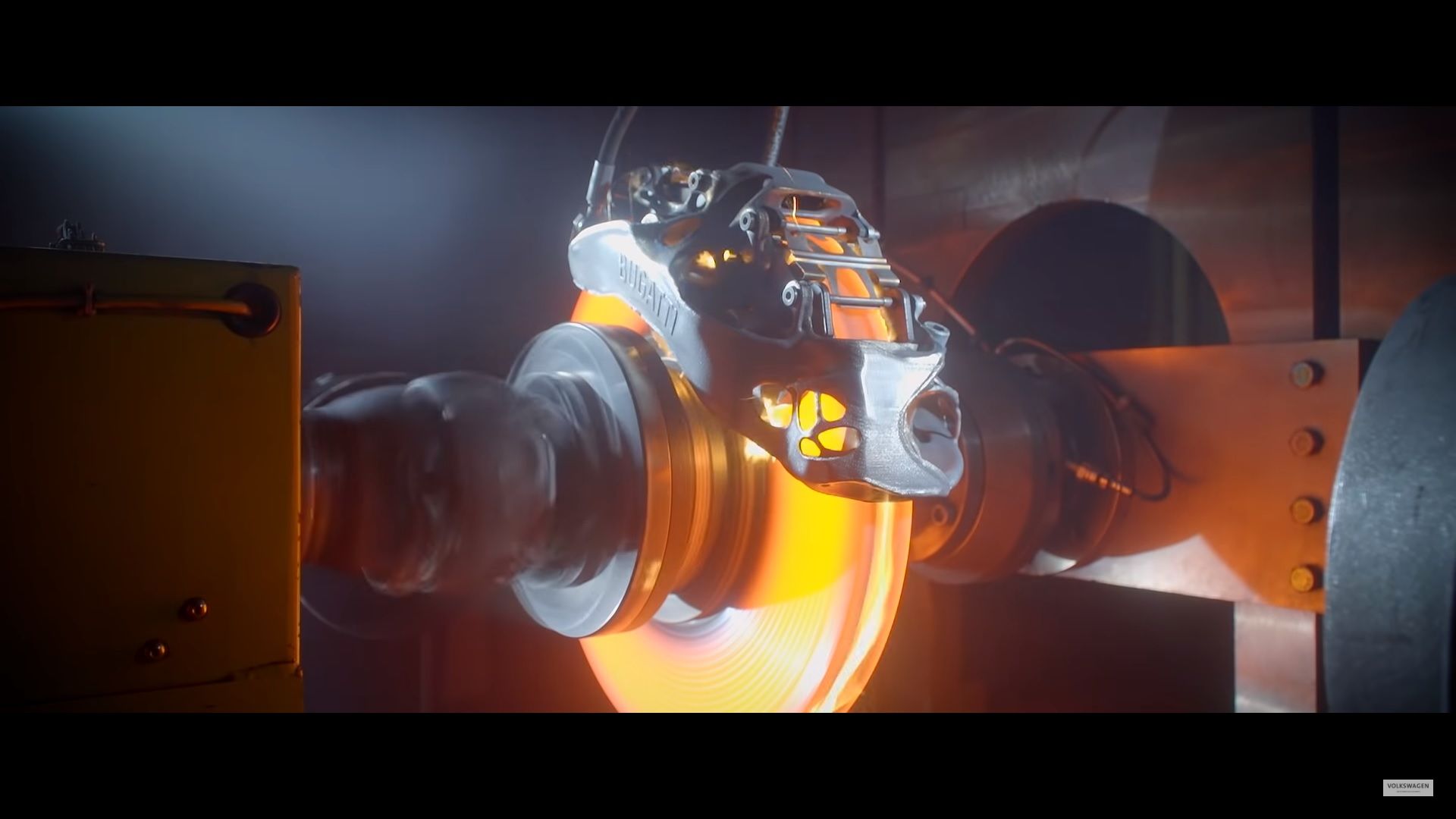

Hit play, and you’ll see Bugatti install a freshly printed caliper to a brake test machine, its shiny metal looking hugely complicated with all kinds of intricate bends and curves. After it’s mounted to the testing rotor, the caliper is put under extreme pressure as the rotor is spun up to the rotational equivalent of 249 mph.

Once it’s up to speed, the technicians activate the binders, and sparks fly as the rotor quickly decelerates. The metal glows red as it gets up to more than 1,800 degrees Fahrenheit, then it spins back up again for another hard stop.

Bugatti repeats the process over and over, and it looks like torture for the metal components. But throughout it all, the 3D printed caliper stands strong.

The caliper itself is made from 3D printed titanium, and looks simply massive - as it should, if it’s gonna be used to slow some of Bugatti’s biggest and baddest machinery. Advantages offered include a lower weight, with this titanium unit tipping the scales at roughly half the weight of a standard Chiron caliper, or 6.4 pounds versus the 11 pounds of the aluminum unit currently in production.

Further advantages for 3D printing include a wider array of customization options, as unlike manufacturing techniques that require a cast or mold, 3D printing just needs a digital design to create an actual part. Once this tech really hits the market, we anticipate a wider array of wheel options, body kit options, interior trim, and the like. Additionally, 3D printing will breathe new life into older cars as well, recreating parts that may have been discontinued years ago.

If you could 3D print your own parts, what would you make? Let us know in the comments section below.

Further Reading

Read our full review on the 2018 Bugatti Chiron.

Bugatti Just 3D-Printed The World’s Largest Titanium Brake Caliper.

The New 3D-Printed Wheels From HRE Have Us Drooling With Anticipation