In preparation for the new U.S. Tier 2 Bin 5 emissions regulations, MMC has announced a project to develop a next generation diesel engine, to be launched in the new Lancer in 2010. Speaking at the MMC press conference MMC Chairman of the Board Takashi Nishioka commented, "With strong support from the Mitsubishi Group, Mitsubishi Motors is now in the middle of implementing the 3-year business plan that started in fiscal 2005.

Under the plan, we are beefing up the management setup of our U.S. operations and reviewing our sales policies and strategies here. We are now in a situation where we can project that fiscal 2006 will produce our first operating profit in four years. Together with all the other Mitsubishi Group companies, we are also working on environmental initiatives, using Mitsubishi Group resources to maximum effect. As part of that process, we are collaborating with Mitsubishi Heavy Industries to develop a next generation diesel engine that will be launched in the North American market in 2010."

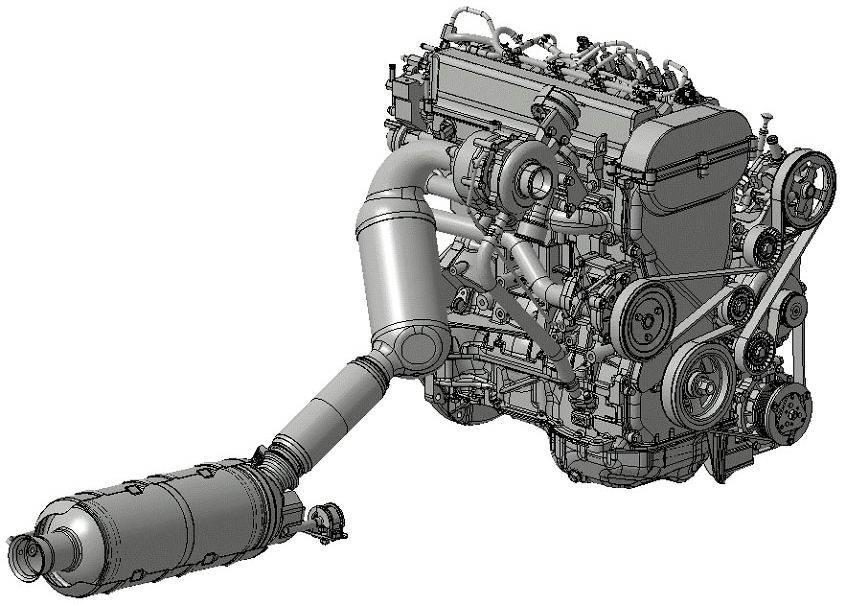

The project to develop a next generation diesel engine for the North American market will be based on the diesel engine that MMC is developing together with Mitsubishi Heavy Industries for European export models. The new engine incorporates a DPF + NOx trap catalyst to ensure compliance with U.S. Tier 2 Bin 5 emissions regulations that require NOx (nitrogen oxides) emissions to be as low as similar emissions from gasoline engines. It will also be compliant with the Japanese post-new long term emissions regulations. Features of this engine will include a lightweight aluminum block, a common rail system with piezo injectors to provide good responsiveness, and a VG/VD turbocharger with boost pressure controllable over a particularly wide range by combining a variable geometry (VG) that enables turbine flow to be varied, with a variable diffuser (VD) that enables compressor flow to be varied. This combination of features will produce an engine that is both very powerful and efficient.

Next Generation Mitsubishi Diesel Engine outline

- The design for the new engine includes a lightweight aluminum block, a common rail system with piezo injectors to provide good responsiveness, and a VG/VD turbocharger with boost pressure controllable over a particularly wide range by combining a variable geometry (VG) for variable turbine flow with a variable diffuser (VD) for variable compressor flow. This combination of features will result in a diesel engine that is both very powerful and efficient.

- The exhaust gas cleaning system is designed for compliance with both U.S. Tier 2 Bin 5 and Japanese post-new long term emissions regulations, utilizing combustion control technology to reduce NOx, together with a DPF + NOx trap catalyst to clean NOx from the exhaust and reduce emissions.