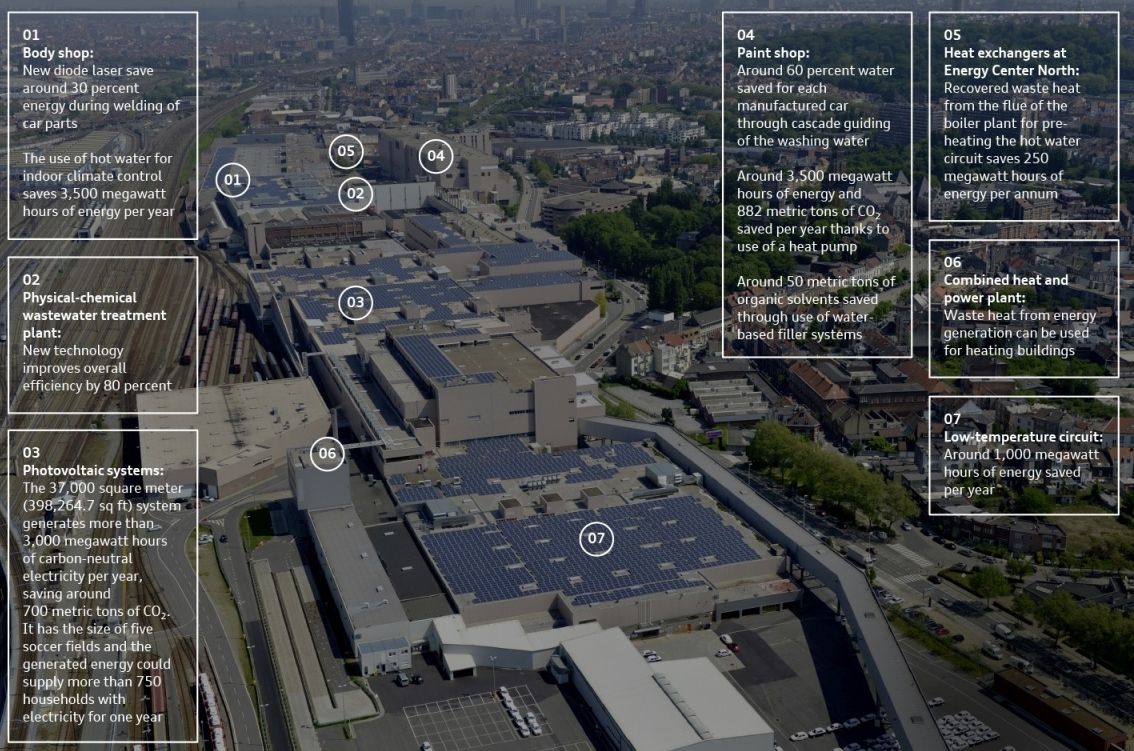

Committed to making its facilities carbon-neutral by 2030, Audi started with the e-tron multi-structure plant that covers 540,000 square-meters and is located in Brussels, Belgium. Audi improved the body shop, paint shop, and assembly shop and added a new battery manufacturing plant.

The Brussels facility is blanketed with a 37,000-square-meter photovoltaic system. This enables the generation of more than 3,000 megawatt-hours of electricity, thus saving 700 metric tons of CO2 per year. The Brussels plant is the first in the world with certified carbon-neutral production in the premium auto segment.

Volkswagen also made an eco promise. By the end of the year the Stuttgart factory, set to start producing all-electric Porsche Taycans, will be carbon-neutral as well.

Because of the complex supply chain for batteries, EV manufacturing is very energy intensive. The environmental NGO Union of Concerned Scientists estimated that manufacturing an EV results in a 15 to 68 percent increase in emissions compared to the production of a conventional vehicle.

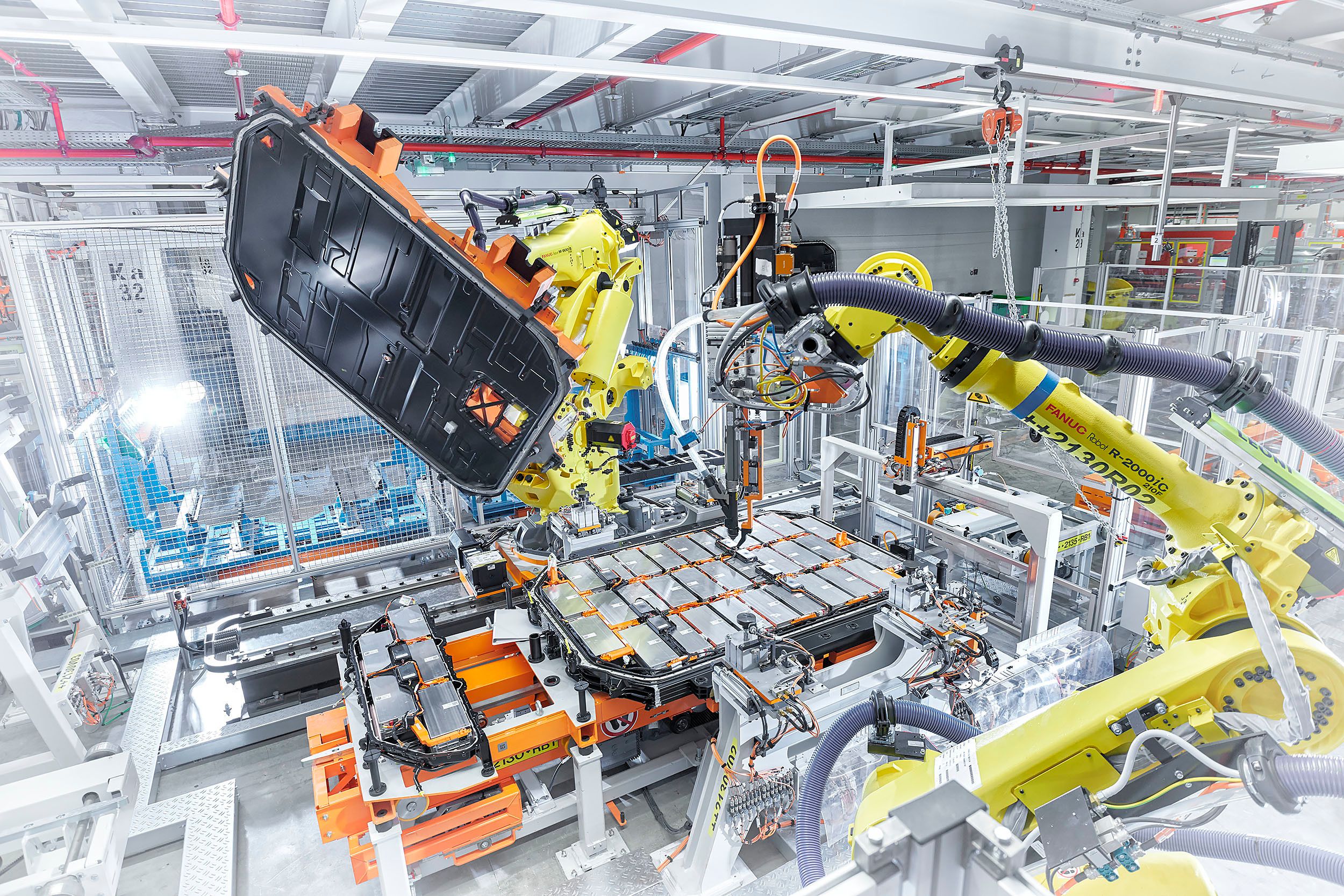

Following the Audi Production System (APS) - which main features are group work and continuous improvement processes - Audi incredibly improved its e-tron facility located in Brussels, Belgium.

By almost integrating the external suppliers and service providers into the production process, Audi boosted the productivity of the plant.

Patrick Danau, the plant's director of production, technology, and logistics, said this helps the automaker increase its efficiency and control battery quality.

Minimizing the energy waste and utilizing different types of energy production, the facility in Brussels is the first plant producing premium, high-volume EV vehicles to be certified as carbon-neutral by the European Commission.

Audi set up a 37,000-square-meter photovoltaic system on the rooftop, which generates more than 3,000 megawatt-hours of electricity per year, thus saving 700 metric tons of CO2.

The solar cells decrease the factory's total grid-based power waste by 95 percent. The factory also uses high-efficient heat exchangers to control the temperature of different areas in the plant, which Audi estimates saves it extra 4,000 tons of CO2 emissions annually.

After its diesel emission scandal, Volkswagen should consider following Audi's green steps with this plant. So far, Volkswagen said that by the end of the year, the Stuttgart factory, set to start producing all-electric Porsche Taycans, will be carbon-neutral as well.