The Porsche 911 GT2 RS is a beast of a car that, as of today, delivers a cool 700 horsepower and 553 pound-feet of torque from a twin-turbo, 3.8-liter, flat-six. It’s fast enough to get to 60 mph in a spleen splitting 2.7 seconds and tops out a respectable 211 mph. Those numbers represent an improvement of 0.8 seconds and six mph over the model it replaced. One could argue, then, that the next-gen 911 GT2 RS doesn’t need more power, but Porsche simply wouldn’t agree. This time, however, extra power and better performance aren’t coming from bigger turbos and more most. No, this time it comes, at least in part, thanks to 3D printed pistons.

Porsche’s 3D Printed Pistons Make for Less Weight and Better Combustion

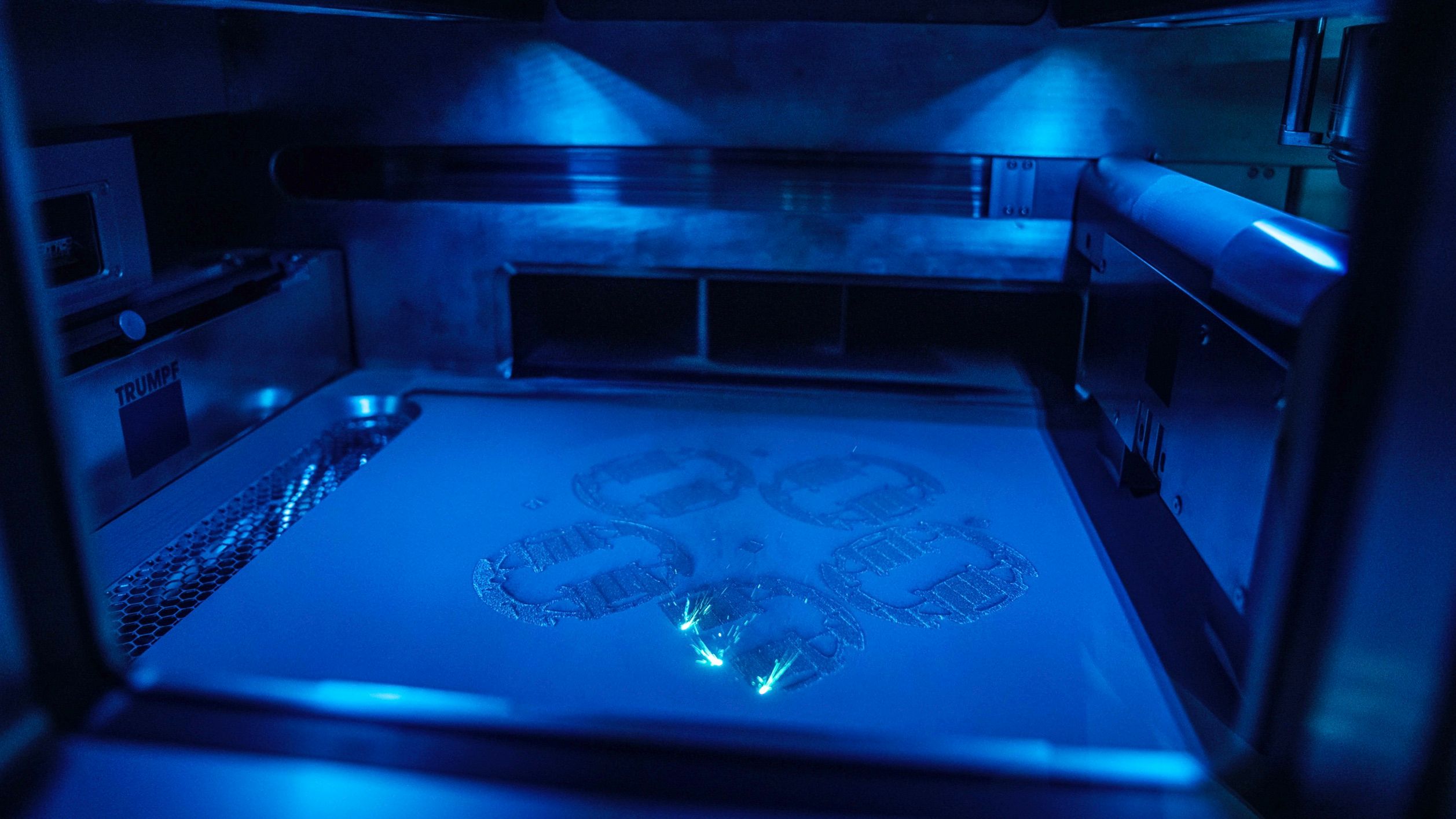

3D printing isn’t new to the world. You’ll probably recall that Porsche has used the technology before to create racing bucket seats, and even Bugatti uses it to make its titanium exhausts. Thanks to a collaboration between Porsche and Mahle and Trumpf, Porsche has unlocked the ability to 3D print pistons – the beating horse inside every internal combustion that’s in production today.

While this might not mean a lot for a car that delivers a meager 300 horsepower, when it comes to high-performance cars like the 911 GT2 RS, we’re talking about an increase in as much as 30 horsepower. Assumingly, that’s without any improvements anywhere else like we saw with the current GT2 RS with larger turbos and increased boost. So, just employing these 3D printed pistons along could push the next-gen GT2 RS into the 720-horsepower range, 30 ponies more than the current model and 20 ponies more than the 911 GT2 RS Clubsport. }

The whole process of making these pistons is 100 times easier to say than actually accomplish. First off, high-purity metal powder is used to construct them. That high-purity metal powder is then fused together in the shape of a piston with laser fusion. Special accommodations have to be made, however, to ensure quality and longevity, so Porsche had to fall back on Zeiss for precise measurement.

Will the Base Porsche 911 or 718 Cayman Have 3D Printed Pistons?

Don’t hold your breath for these new 3D printed pistons to trickle down to the base 911 or 718 anytime soon. As you can imagine, the process is outrageously expensive. Porsche hasn’t disclosed cost, but there’s a good reason that the Porsche 911 GT2 RS is being used as a testbed of sorts for their introduction. The last model came dangerously close to the $300,000 mark, so if these make it into production examples of the next-gen GT2 RS, cost recuperation won’t be difficult. Putting them in a car that comes in a 30 to 40-percent of that price, however, probably isn’t feasible. It may happen someday, but for the foreseeable future, this kind of tech will be limited to the high-dollar, big-boy cars that most of us only dream of owning.