To say that the Aston Martin Valkyrie hypercar is exclusive is an understatement. With only 150 units to be made, every model produced is a milestone of its own, especially if it's the first-ever unit to roll of the production line.

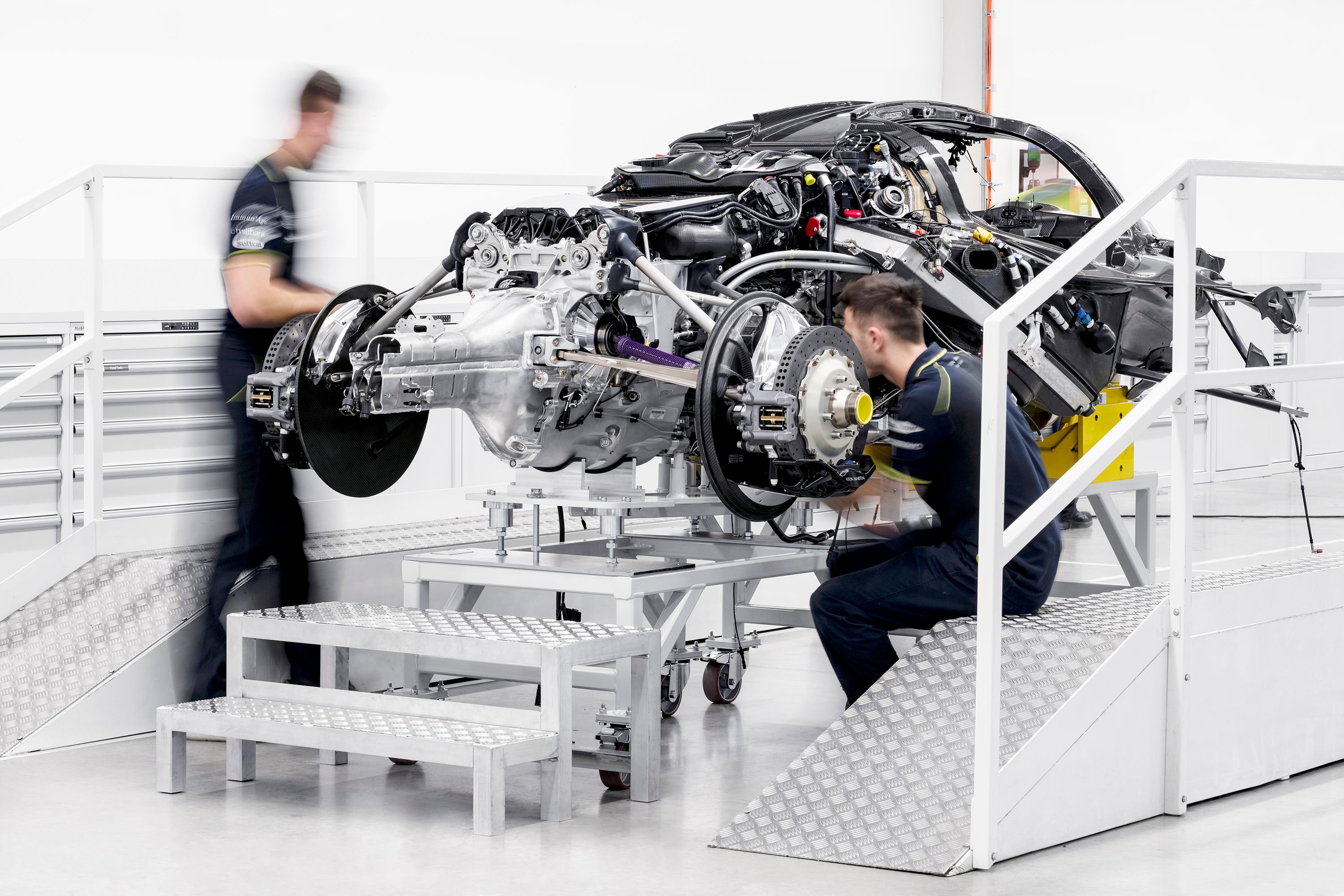

The first-ever customer unit of the Aston Martin Valkyrie has recently rolled off the company's assembly line in Gaydon, UK, and is handled by a dedicated team that takes care of the vehicle from assembly right until delivery.

As a chief rival to the Mercedes-AMG One, the Aston Martin Valkyrie uses a lot of technologies from Formula 1. It is no surprise then that Aston Martin's engineers want to take a lot of time in producing each vehicle, 2,000 hours to be precise.

Before the Valkyrie reaches customers, each vehicle must be tested on track first at Aston Martin's facility in Silverstone. This is also where most of the hypercar's development took place.

The hypercar was developed together with Red Bull's Chief Technical Officer, Adrian Newey, in which he commissioned with Cosworth the development of the hypercar's 6.5-liter naturally-aspirated V12.

The engine alone produces around 1,000 horsepower and has a redline of 11,100 rpm, making it the most powerful and highest-revving naturally-aspirated engine ever fitted to a road car.

Mated to it is an electric motor that produces an additional 160 horsepower and 280 Nm of torque. As a result, this hybrid hypercar has a total system output of 1,160 horsepower at 10,500 rpm and 900 Nm of torque at 6,000 rpm. Power is then sent to the rear wheels via a 7-speed single-clutch automated manual made by Ricardo.

With all 150 units already spoken for, let's just hope that the hypercars' lucky owners will actually take it out on the track rather than simply treating the Valkyrie as mere investments, sitting unused in a temperature-controlled garage.