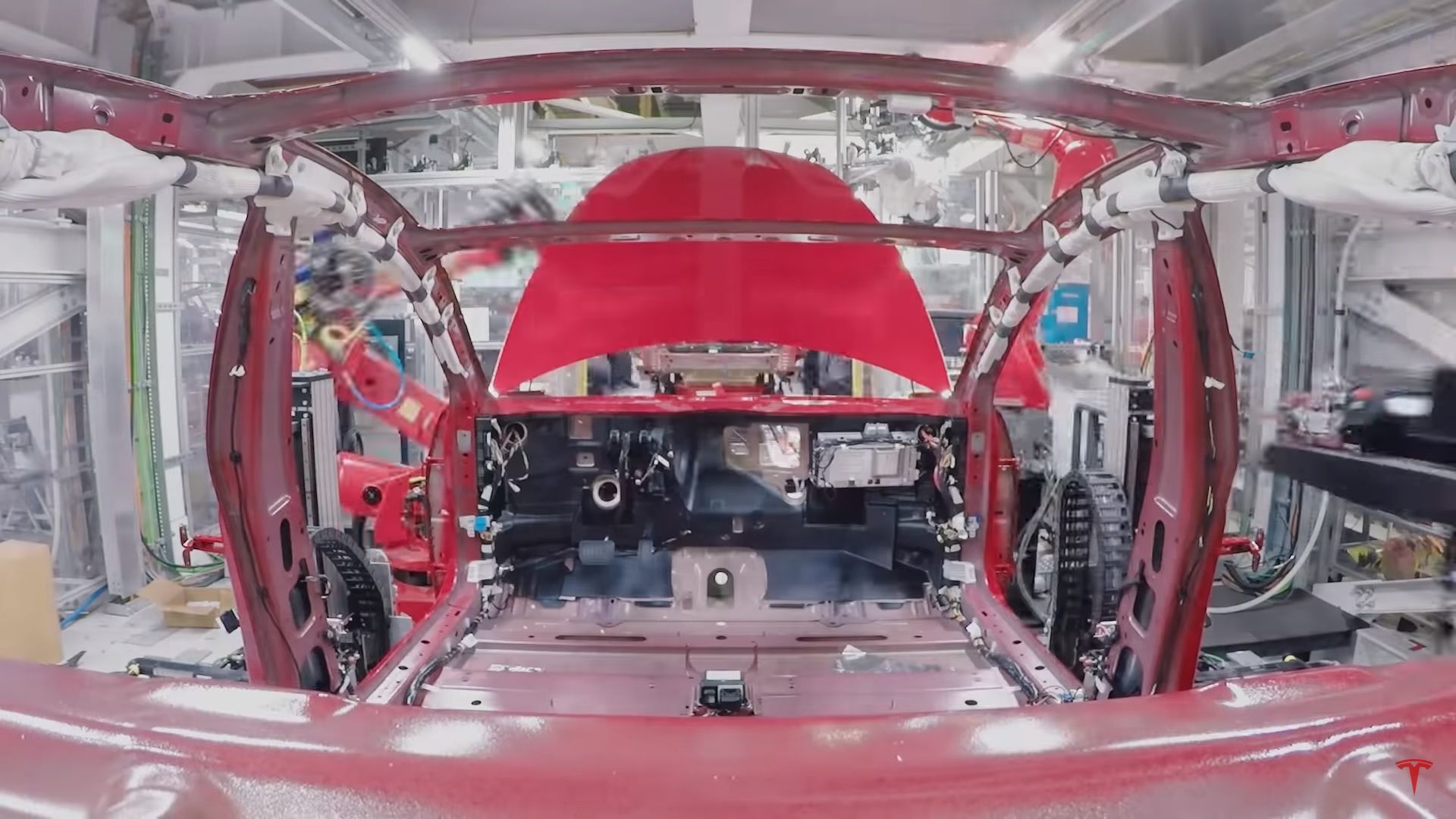

Tesla employs a highly automated assembly process that was implemented in full for the Model 3. Humans still play a part in it, but as you’ll see in this time-lapse that follows a Model 3 from bare shell all the way to finished automobile, there's more automation than human intervention. Even cooler, however, is that you can see the whole process in just 48 seconds.

What struck me when watching the short video was the fact that even the seating for the workers as they do fiddly jobs inside the car is provided by a robotic arm. It all looks incredibly efficient, streamlined, and not all that complicated because many parts come pre-assembled - for instance, the dashboard is placed inside the car as a unit, and it is then quickly powered on in Factory Mode.

>

Regarding the quality issues, things have improved a bit from the first cars that were built compared to the most recent ones, although owners are still reporting misaligned panels and pieces of trim, as well as a plethora of different paint defects.

Read our full review on the 2018 Tesla Model 3.

Further Reading