A flexible fueled vehicle (FFV) has a single fuel tank, fuel system, and engine. The vehicle is designed to run on unleaded gasoline and an alcohol fuel (usually ethanol) in any mixture. The engine and fuel system in a flex-fuel vehicle must be adapted slightly to run on alcohol fuels because they are corrosive. There must also be a special sensor in the fuel line to analyze the fuel mixture and control the fuel injection and timing to adjust for different fuel compositions. The flex-fuel vehicle offers its owner an environmentally beneficial option whenever the alternative fuel is available.

History of the Flex-Fuel Vehicle on the American Market

North American vehicles from approximately 1980 onward can run on 10% ethanol/90% gasoline (e.g., E10) with no modifications. Prior to 1980, many cars imported into the United States contained rubber, aluminium, and other materials that were generally non-compatible with any ethanol in their fuel delivery systems, and these cars experienced problems when E10 was first introduced.Cars made in the US from the late 1970's onward can run on E10 with no modifications. E10 fuel is widely available. Going beyond 10% ethanol generally requires special engineering.

In the United States, many flexible-fuel vehicles can accept up to 85% ethanol (E85). The fuel mixture is automatically detected by one or more sensors, and once detected, the ECU tunes the timing of spark plugs and fuel injectors so that the fuel will burn cleanly in the vehicle's internal combustion engine. Originally, sensors in both the fuel-line and in the exhaust system were used for flexible fuel vehicles. In recent years, manufacturers have instead opted to use only sensors in the exhaust manifold, before the catalytic converter, and to eliminate the fuel inline sensor. As E85 is more corrosive, special fuel lines are also required. Some manufacturers also required a different motor oil be used, but even this requirement is now dropped for all but one manufacturer.

In 1998, General Motors Corporation introduced their first light truck (an S10, with 2.2L engine) in a flexible-fuel configuration. In 1999, Ford Motor Company introduced a flexible-fuel option on its Ford Ranger pickup trucks, and it has also been an option on the company's Taurus model. Other manufacturers such as Mercedes-Benz, Chrysler/Dodge (namely certain models of Caravan) also are E85/Flexible fuel vehicles. Flexible fuel vehicles are often identified as such on the driver's side door, on the inside of the fuel fill access door, and by the VIN number.

As of 2005, most existing vehicles that are available to the public with flex-fuel engines are sport-utility vehicles or others in the "light truck" class. Sedans, wagons, and others are usually only available in flexible-fuel configurations as part of fleet vehicle purchases by companies. Starting in 2006, though, more widespread availability is planned for standard models intended for non-fleet sales.

A 1988 federal law provides an incentive for creating flexible fuel vehicles in the form of credits that can be used to relax Corporate Average Fuel Economy fuel efficiency standards. It is alleged that this efficiency relaxation has decreased overall US fleet efficiency, thereby resulting in increased nationwide fuel consumption.

Over 4 million flexible-fuel vehicles are currently operated on the road in America, although a 2002 study found that less than 1% of fuel consumed by these vehicles is E85. Flexible fuel vehicles as identified by the National Ethanol Vehicle Coalition.

How E85 is made

Ethanol is an ancohol-based alternative fule produced by fermenting and distilling starch crops like corn, barey and wheat, used to increase octane and improve emissions. Ethanol is blended with gasoline to create E85: 85% ethanol and 15% gasoline.

The technology is based on checking the alcohol content in a gasoline blend through sensors and on the automatic adjustment of engine operation to the most favorable conditions for the blend in question. One could say that this technology transformed the conventional gasoline engine into an "intelligent" engine.

The conversion will require the purchase of flex-fuel cars that are capable of running the high ethanol mixture. In some states, ethanol has already been added to the fuel, but only in a small ratio (an additive). According to CBS News “only 5 million of the country's 133 million cars can use E85.” The beauty of the flex-fuel cars is that they can run either on regular gas or an ethanol mixture up to 85%.

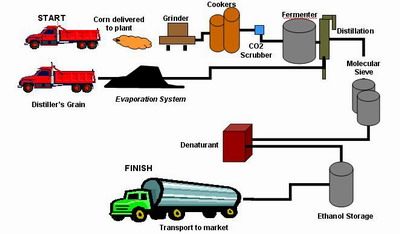

Using corn as the feedstock is one of the most common ways to produce ethanol. Dry mill ethanol production is a premier manufacturing production system to extract starch contained in the corn.

Ethanol plants are fermentation facilities in which corn is ground and mixed with water to form a mash. Mash is then heated, and enzymes are added to convert starch into fermentable sugars. Fermentation then occurs when yeast is added to convert the sugars into ethanol and carbon dioxide.

Fermentation produces a mixture called "beer" containing about 15% ethanol and 85% water. "Beer" is boiled in a distillation column to remove the water, which results in ethyl alcohol that is 90% to 95% pure. This mixture is then dehydrated, which increases the alcohol content to 99% or more. At this point the product is mixed with a denaturant for commercial sale, which renders the product unfit for human beverage consumption.

Solids removed during the distillation process are centrifuged and/or evaporated and then sent to a dryer system to reduce the moisture content to approximately 10%. This value-added co-product is DDGS (distiller's dried grain with solubles). DDGS is the corn kernel minus the starch.

Flex-Fuel Vehicles in USA

The next FFV vehicles are available in USA:

- Chrysler Sebring

- Dodge Caravan, Durango, Grand Caravan, Ram Pickup, Stratus

- Ford Crown Victoria, F-150, Grand Marquis, Taurus

- Chevrolet Avalanche, Silverado, Suburban, Tahoe, Impala, Monte Carlo

- GMC Sierra, Yukon, Yukon XL

- Nissan Titan