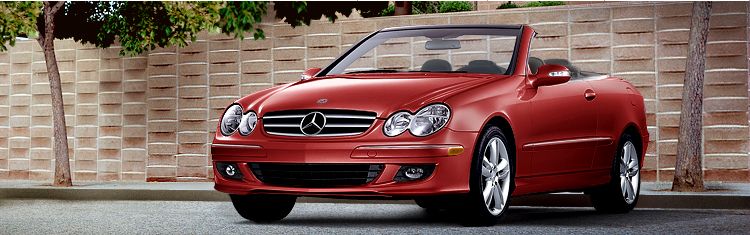

Bolstered by a new V8 engine developing 285 kW/388 hp, the CLK 500 Coupé and Cabriolet models now serve up sports car-esque driving pleasure.

mercedes-clk-class

- Make: Array

- Model: mercedes-clk-class

2006 Mercedes CLK-Class

- Engine/Motor: 5.5 liter V8

- Torque: 390

- Transmission: 7-G TRONIC

- [do not use] Vehicle Model: Array

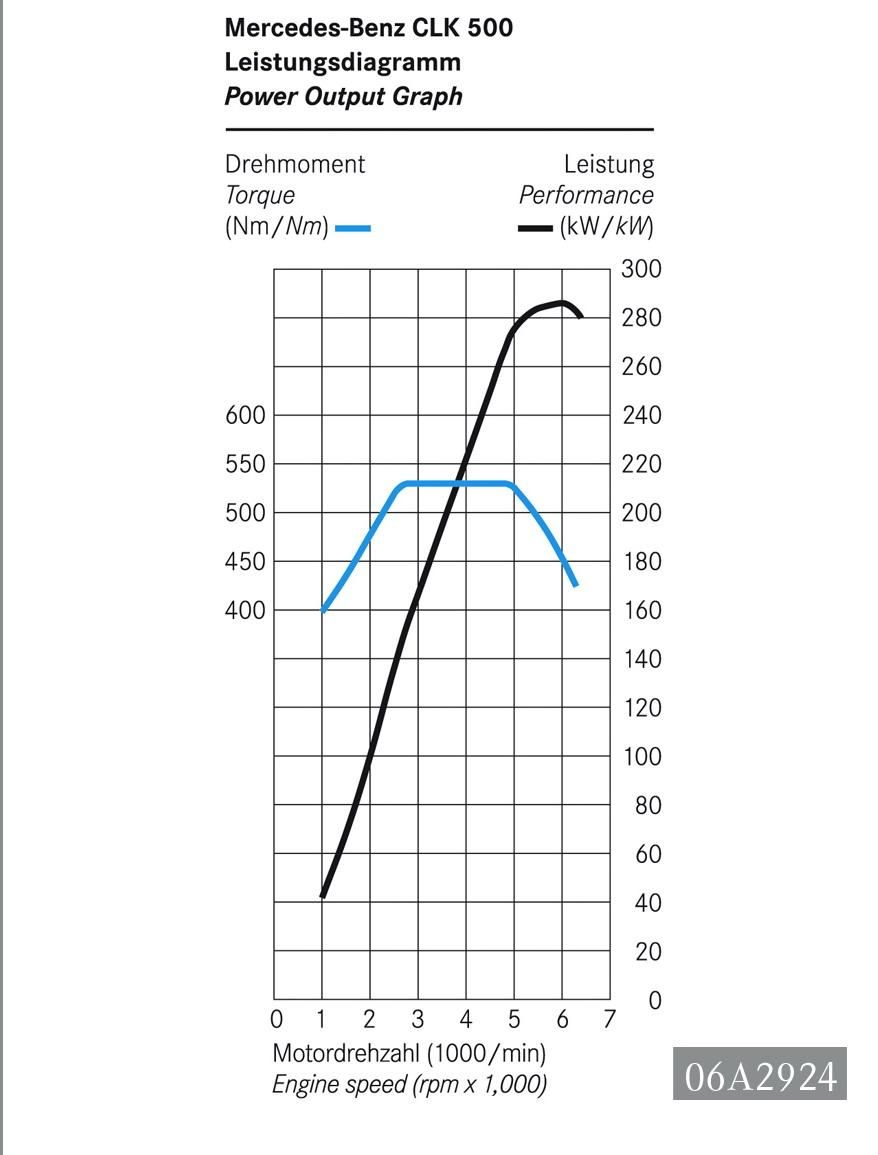

The newly developed 5.5-litre V8 engine boasts a peak torque of 530 Nm (outgoing model: 460 Nm), allowing the CLK-Class to deliver a virtuoso performance: the sprint from 0 to 60 mph takes just 5.2 seconds (outgoing model: 5.9 seconds), while the top speed is 250 km/h (electronically limited). Despite the 26 per cent boost in power, NEDC combined fuel consumption remains at an impressive 11.4 - 11.5 l per 100 km, matching the excellent figure posted by the previous model.

Now customers can further upgrade their CLK models by adding the sports and styling package, which includes leather multicontour seats, metallic paintwork, an AMG ergonomic sports steering wheel with shift paddles (with the automatic transmission) and aluminium sports pedals. The six and eight-cylinder petrolengined versions with an automatic transmission boast the special 7G-TRONIC Sport seven-speed transmission (standard in the CLK 350 and 500).

The appearance of the Mercedes-Benz CLK-Class also expresses the increased power of the extensively upgraded coupe and convertible. The redesigned front bumpers with their striking wedge shape and larger air intakes create a more dominant look, as does the modified radiator grille with three instead of the previously four louvers. In the future, the CLK’s AVANTGARDE equipment line will feature 17-inch five-spoke alloy wheels as standard, while the ELEGANCE line will have nine-spoke alloy wheels (16-inch; 17-inch wheels for the CLK 320 CDI and up).

With their proverbial attention to detail, the Mercedes designers have not only upgraded the CLK’s interior but also ensured that the various equipment lines have become even more distinct. The AVANTGARDE line vehicles will, for example, be equipped with new black seat coverings as standard, consisting of a combination of fabric and ARTICO imitation leather. Alternatively, an all-new leather design is available as an option in which seats, door centre panels and rear side panels feature contrasting colours. The AVANTGARDE’s instrument panel comes with a matte aluminium faceplate, white dials with special lettering, and chrome rings for the round gauges.

In terms of exterior features, the package comprises 18-inch AMG light-alloy wheels, AMG bodystyling - for the front and rear apron and the side skirt panels - as well as an AMG spoiler lip on the boot lid and a chromed AMG twin tailpipe. These visual enhancements lend both the Cabriolet and the Coupé an even more dynamic aura. Plus the sports suspension and perforated front brake discs make the CLK even more of a pleasure to drive. The sports and styling package is available now for € 4402.00 (5495$) (incl. 16 % VAT).

-----

Design

To an ever greater extent, design worlds are overlapping, flowing into one another and drawing their influences from a shared pool. Mercedes-Benz and the renowned Italian design guru Giorgio Armani have recognised this and have now created a remarkable crossover combining car design and fashion design. The outcome takes the form of the “Mercedes-Benz CLK designo by Giorgio Armani”. The fashion designer has remodelled this exclusive designo limited-edition version of the four-seater Mercedes-Benz CLK 500 Cabriolet and has remodelled Cabriolets to express his refined sense of the aesthetic and his hallmark style. Indeed, this special model, limited to just 100 units, rapidly found its way into customers’ hearts. Mercedes-Benz is currently supplying the first of these CLK-Class cars in Giorgio Armani style to its customers. A unique matt sand tone of paint was chosen to reflect core Giorgio Armani values, harmoniously matched with an interior appointed with luxury materials to project a refined and at the same time sporty masculine image.

Intricately worked brown designo leather and high-tech textiles

The interior seat covers and a silky smooth high-tech foil echo the tone of exterior paintwork creating a harmonious link between inside and out. Giorgio Armani also achieved remarkable effects by taking these materials out of their familiar context and combining them in an unusual manner to create something altogether new. In this instance, he drew together the classic, intricately worked brown designo leather and high-tech textiles from the world of sports clothing. The three-dimensional structure and restrained sheen of this fine-weave fabric delivers optimum ventilation on the seats. Stylish pompadour leather pockets behind driver and passenger seats not only provide storage space, they also demonstrate just how much care and attention went into working these materials. The upper section of the instrument panel has a slightly matt anthracite finish to avoid disruptive reflections in the windscreen. The lower section is in the “sabbia” tone, creating a contrast and also echoing the paint colour of the vehicle exterior.

The upper section of the instrument panel has a slightly matt anthracite finish to avoid disruptive reflections in the windscreen. The lower section is in the “sabbia” tone, creating a contrast and also echoing the paint colour of the vehicle exterior.

The driver directs the “Mercedes-Benz CLK designo by Giorgio Armani” using an anthracite-coloured multifunction steering wheel clad in perforated leather, making it pleasant to the touch while also providing perfect grip.

Inside the car, Giorgio Armani has focused deliberately on classic wood veneers, dispensing entirely with chrome to cut down on reflected glare as much as possible. Instead, the decorative finishers are all covered in brown designo leather and all metal finisher elements are coloured with a prestigious matt finish known as the “aged look”. The centre console also bears the embossed lettering “designo by Giorgio Armani”.

Open-air motoring pleasure for four people

The technology platform of the “Mercedes-Benz CLK designo by Giorgio Armani“ is the CLK 500 Cabriolet. This guarantees superlative technology and fascinating styling, as well as open-air motoring pleasure in ultimate comfort for four people. The “Mercedes-Benz CLK designo by Giorgio Armani“ is fitted with the new design of front bumper, created in April 2005, featuring distinctive arrow markings and enlarged air intake ducts as well as the modified 3-slat radiator grille. The visual appearance of Giorgio Armani’s co-designed CLK-Class Cabriolet is further enhanced by the addition of AMG body styling elements. These include dynamic front and rear aprons, emphatic side skirts and 18-inch AMG light-alloy wheels painted vehicle colour and sporting low profile tyres: 225/40 R 18 (front) and 255/35 R 18 (rear).

The “Mercedes-Benz CLK designo by Giorgio Armani“ is fitted with the new design of front bumper, created in April 2005, featuring distinctive arrow markings and enlarged air intake ducts as well as the modified 3-slat radiator grille. The visual appearance of Giorgio Armani’s co-designed CLK-Class Cabriolet is further enhanced by the addition of AMG body styling elements. These include dynamic front and rear aprons, emphatic side skirts and 18-inch AMG light-alloy wheels painted vehicle colour and sporting low profile tyres: 225/40 R 18 (front) and 255/35 R 18 (rear).

The V8 engine delivers 225 kW/306 hp and accelerates the Cabriolet from nought to 100 km/h in just 6.2 seconds. Despite this tremendous performance, the engine only consumes 11.1 litres of fuel per 100 kilometres (NEDC fuel consumption). Twinned with the new 7G-TRONIC, the only automatic car transmission in the world with seven forwards and two reverse gear ratios and the superbly tuned sports suspension, this car guarantees its owner unbridled dynamism and a superlative motoring experience.

An exceptionally robust body shell, automatic rollover protection, adaptive airbags for driver and passenger, head/thorax side airbags as standard for driver and front seat passenger, back seat side bags, belt tensioners on all seats and a sensor-controlled rollover bar assure high standards of occupant safety.

Exclusive equipment comes as standard

In keeping with these challenging standards, the Giorgio Armani styled CLK Cabriolet satisfies almost every conceivable wish in terms of interior appointment. Standard equipment includes the ultra-convenient THERMOTRONIC automatic air-conditioning system with sun sensor, stereo radio and surround sound system with ten speakers and 8-fold 40 Watt amplifier power, electrically operated front seats with memory function, seat heating, low-beam assistant, PARKTRONIC, rain sensor for the windscreen wipers and cruise control with SPEEDTRONIC. Giorgio Armani came into contact with the world of automotive design through his meeting with Mercedes-Benz

Giorgio Armani came into contact with the world of automotive design through his meeting with Mercedes-Benz

The idea behind the joint cooperative venture between the Stuttgart-based car maker and the Milan-based fashion designer arose after a successful world tour of Giorgio Armani exhibits in 2003 sponsored by Mercedes-Benz. In close collaboration with the DaimlerChrysler Advanced Design Center in the northern Italian town of Como, Giorgio Armani came into contact with the field of automotive design for the first time. After jointly creating a show car which was unveiled at Milan Fashion Week in the autumn of 2003, the President and Chief Executive of Giorgio Armani Group stated: “There is every justification for Mercedes-Benz laying claim to the outstanding quality, style and elegance of its cars. It was most interesting for me to find just how many areas of common ground are in fact shared by our design philosophies and our approaches to work.”

-----

Body

The body of the new Mercedes Cabriolet is based on the extremely solid CLK-Class Coupé platform, featuring an elegant system of panels that scores top marks for torsional stiffness, stability, safety and aerodynamics.

Hence the ingredients for creating a cabriolet exuding classic Mercedes qualities were there right from the start. In short, the body structure of the CLK Cabriolet is just as stiff as that of the impressive Coupé, despite the absence of the roof structure. Two factors were crucial in enabling the engineers to achieve this objective: intelligent use of materials and a host of additional design measures.

Around 40 percent of the new CLK Cabriolet's bodyshell is made from high-strength steel alloys – an increase of 15 percent compared to the previous model. High-strength sheet steel – a material which minimises weight whilst maximising stability – is used for the majority of the components that are decisive for ensuring the high level of crash safety and long service life typical of Mercedes vehicles. Mercedes-Benz has succeeded in further optimising torsional stiffness, an important factor in determining the body's vibration response: the figure is now down to 4.23 mm per metre, which is around twelve percent less than the figure posted by the previous CLK Cabriolet. Similarly, bending resistance – measured on the transmission tunnel – is more than twelve percent lower than the already exemplary level recorded by the predecessor model.

Around 40 percent of the new CLK Cabriolet's bodyshell is made from high-strength steel alloys – an increase of 15 percent compared to the previous model. High-strength sheet steel – a material which minimises weight whilst maximising stability – is used for the majority of the components that are decisive for ensuring the high level of crash safety and long service life typical of Mercedes vehicles. Mercedes-Benz has succeeded in further optimising torsional stiffness, an important factor in determining the body's vibration response: the figure is now down to 4.23 mm per metre, which is around twelve percent less than the figure posted by the previous CLK Cabriolet. Similarly, bending resistance – measured on the transmission tunnel – is more than twelve percent lower than the already exemplary level recorded by the predecessor model.

Diagonal struts on the underbody also play an important part in ensuring the exemplary vibration response of the Cabriolet body. At the front end, they connect the integral aluminium subframe – on which the engine, steering and front axle are mounted – to the front edge of the side members. At the rear, the struts on both sides are connected to the side members and an additional spare wheel well reinforcement. The mass damper attached to the front module also makes an important contribution towards the high level of vibrostability in the new Mercedes Cabriolet. It is designed and positioned to ensure that its moving damper weight (8.9 kg) compensates for body vibrations which would otherwise be felt on the steering wheel and in the vehicle interior.

Front and rear modules: easy-repair technology with crash boxes

As they did for the C-Class, E-Class, S-Class and SL-Class, the Mercedes engineers have developed special front and rear modules which absorb crash energy at impact speeds of up to 15 km/h, thus ensuring that the supporting structures behind remain undamaged. Bolted connections make the modules cheap and easy to replace, eliminating the need for straightening, welding and repainting.

The front module consists of a series of components that are bolted together. At its core are two steel crash boxes and an extruded aluminium crossmember. In addition, there are two brackets for mounting the radiator and, on both sides, multi-section steel frames for mounting the headlamps in the front module. At the rear, the replaceable body module also consists of two steel crash boxes and an aluminium crossmember, capable of absorbing crash energy at impact speeds of up to 15 km/h.

The doors of the new CLK Cabriolet consist of one inner and one outer sheet-steel shell with several reinforcing sections. There is also a flexible, tubular bracket in the lower section, which reduces deformation in the event of a side impact. Mercedes-Benz used higher-grade material to develop separate panels for securing the door hinges, the aim being to further enhance load resistance in these areas.

The doors of the new CLK Cabriolet consist of one inner and one outer sheet-steel shell with several reinforcing sections. There is also a flexible, tubular bracket in the lower section, which reduces deformation in the event of a side impact. Mercedes-Benz used higher-grade material to develop separate panels for securing the door hinges, the aim being to further enhance load resistance in these areas.

Boot lid: integrated aerials for radio, navigation and telephone

The boot lid is yet another innovative feature of the Cabriolet body, since the high-grade plastic is of major benefit in terms of the Cabriolet's elegant appearance: this particular high-tech material enables the aerials for short, medium and long-wave radio reception – as well as the aerials for the optional car phone and navigation system – to be integrated in the boot lid so that they remain out of sight. This is not possible with conventional steel designs, since signal reception would be impaired. Further aerials are built into the windscreen.

Corrosion prevention: double-coated panels

The bodyshell is practically immune to corrosion by virtue of its galvanised panels. In addition, around half of these galvanised panels are treated with an organic paint that also contains zinc pigments. Extensive underfloor panelling made of fibreglass-reinforced plastic enables the Mercedes engineers to dispense with conventional, environmentally harmful underfloor protection made from PVC. The paints used for the new CLK-Class Cabriolet are all environmentally compatible, water-soluble products, which fulfil stringent Mercedes quality criteria in terms of colour, gloss, resistance to ageing, scratch-proof properties and chip resistance. Like all Mercedes passenger cars, the new CLK Cabriolet is covered by the 30-year Mobilo-life warranty.

Dimensions: larger body for even more space and comfort

With an exterior length of 4638 mm, the CLK-Class Cabriolet and Coupé are also unique within the Mercedes range when it comes to body dimensions. They are positioned between the C-Class and the E-Class in this regard: the CLK-Class is 112 mm longer than the C-Class Saloon and 180 mm shorter than the Mercedes-Benz E-Class. Compared to its predecessor, the new CLK Cabriolet is 71 mm longer, 18 mm wider and 33 mm higher. These extended dimensions mean that the driver and passengers now enjoy even greater space and comfort.

Fabric soft-top: filigree design offering a host of benefits

Development of the fabric soft-top was based on a combination of the latest know-how acquired by experienced cabriolet specialists and state-of-the-art technology. The new CLK Cabriolet therefore betters the already high quality of its predecessor in this discipline also. When developing the Cabriolet, the aim of the designers and engineers was to recreate the powerfully sweeping roof line and elegant, slender C-pillar configuration of the Coupé so as to retain two key elements of the CLK design. This aim has been achieved as the two-door Cabriolet cuts an impeccable figure and displays impressive sporty elegance whether the soft-top is raised or lowered. This impression is reinforced by the extremely smooth outer surface of the soft-top as well as a special technology that ensures a constant fabric tension at all times.

In addition, the CLK design concept – incorporating slender A-pillars and C-pillars, large, frameless side windows and an 8.5 percent larger rear window – provides drivers with real added benefit on a practical level: all-round visibility is now more than 85 percent when turning, changing lanes, manoeuvring or parking – a new record in this cabriolet segment.

In addition, the CLK design concept – incorporating slender A-pillars and C-pillars, large, frameless side windows and an 8.5 percent larger rear window – provides drivers with real added benefit on a practical level: all-round visibility is now more than 85 percent when turning, changing lanes, manoeuvring or parking – a new record in this cabriolet segment.

Insulation: exemplary acoustic damping and superb winter performance

The new fabric soft-top for the CLK Cabriolet consists of around 830 parts that are joined together by hand in an assembly process involving some 550 different steps. The soft-top frame is a steel-aluminium construction with its main mounts each connected to the body at three points. This frame is spanned by an elaborate, multi-layer fabric roof:

- The weather-resistant, three-layer fabric soft-top is available in black, blue or grey.

- The six-layer non-woven padding is around 25 mm thick and covers the entire roof area as well as the insides of the C-pillars and the areas next to the rear window. The engineers have thus provided excellent heat insulation, meaning that the CLK Cabriolet is just at home in winter as it is in summer. In conjunction with other aeroacoustic measures, the soft-top padding ensures highly effective noise insulation. At 160 km/h the interior noise level is 76 decibels at the front and 77.7 decibels at the rear (dB (A)). It is therefore audibly lower – by up to 1.9 dB (A) – than in the case of the predecessor model, meaning that the new CLK Cabriolet also sets the benchmark in its class when it comes to low-noise operation.

- The interior lining forms the third layer of the fabric soft-top and also covers the entire roof area. It is available in "pebble beige" or "alpaca grey".

Operation: fully automatic soft-top opening in 20 seconds

One simple operation is all it takes to open the fully automatic soft-top: the prominent push-pull switch on the centre console or the remote control device in the electronic key trigger the soft-top hydraulics in an instant. With the help of an electric motor, the drive unit below the soft-top well generates a pressure of 190 bar for operating a total of seven cylinders. Furthermore, 13 limit switches and an ECU monitor the entire sequence which takes no more than 20 seconds.

Before the soft-top disappears under the cover with the "air-domes" at the rear of the CLK Cabriolet, the fully lowerable side windows are opened automatically, so as to ensure unbridled open-air driving enjoyment.

A mere push of the button on the centre console is also all that is needed to close the soft-top; the hydraulic system is activated and automatically locks the roof to the top edge of the windscreen within 20 seconds.

An indicator lamp in the soft-top switch remains lit whilst the soft-top is moving and starts flashing if the soft-top is not locked correctly while the vehicle is in motion. In the latter case, an alarm also sounds. The soft-top can be raised and lowered automatically at speeds of up to eight km/h.

Boot volume: best in this vehicle segment

The new CLK-Class Cabriolet has the largest boot volume in this market segment. The 390-litre capacity (VDA measuring method) represents an increase of 40 litres compared to the previous model. When the soft-top is open, the boot holds 276 litres (predecessor: 237 litres).

After opening, the fabric roof is housed in a soft-top well behind the rear bulkhead. This well serves as an extra stowage compartment when the soft-top is closed. A liftable boot divider separates the soft-top well from the boot; this divider must be closed in order to close the soft-top. Optional equipment for the CLK Cabriolet now includes a skibag which is located behind the rear centre armrest and can carry two pairs of skis.

The boot lid can be conveniently opened by remote control – using either the button on the electronic key or the controls on the interior panel of the driver's door. Two gas pressure springs ensure that the boot lid swings open fully.

-----

Technology

The Mercedes-Benz CLK-Class has been on the road to success since May 2002 (Cabriolet: May 2003) and has won the hearts of more than 135,000 male and female drivers to date. Over the same period, the sales figures are approx. 25 percent above those of the preceding models in the case of the CLK Coupé, and approx. 80 percent better in the case of the CLK Cabriolet.

With this model facelift Mercedes-Benz is emphasising the sporty and dynamic character of the CLK-Class. A major contributor to this is the DIRECT CONTROL technical package which includes a six percent more direct steering ratio, comfort-optimised torque strut bearings at the front axle, larger spring link bearings at the rear axle and reconfigured ESP®. As a result both the CLK-Class Coupé and Cabriolet offer typical Mercedes ride comfort together with even better handling dynamics and greater agility on bends. Mercedes engineers have also revised the standard six-speed transmission, and the DIRECT CONTROL technology with a shorter gearshift travel makes rapid and precise gear changes possible.

Mercedes engineers have also revised the standard six-speed transmission, and the DIRECT CONTROL technology with a shorter gearshift travel makes rapid and precise gear changes possible.

Tyres with a run-flat system are available in the CLK-Class for the first time, and Mercedes-Benz combines these with an automatic pressure loss warning system. This system is based on the technology of the Electronic Stability Program (ESP®) and warns the driver via the central display in the event of a sudden pressure loss in one of the tyres. Thanks to self-supporting tyre flanks, the car is able to continue its journey for up to 50 kilometres at a maximum speed of 80 km/h.

CLK 500: Five percent fuel saving with standard 7G-TRONIC

The new 7G-TRONIC transmission is standard equipment in the top CLK 500 model in future. The world’s only automatic car transmission with seven forward and two reverse gears reduces the acceleration time from zero to 100 km/h, ensures even faster overtaking and at the same time reduces fuel consumption by up to 0.6 litres per 100 kilometres. The relevant data are shown below (figures in brackets: preceding model with five-speed automatic transmission):

CLK 500 Coupé

- 0-100 km/h: 5.9 s (6.0 s)

- 60-120 km/h: 5.2 s (6.2 s)

- NEDC consumption: 10.9 l/100 km (11.5 s)

CLK 500 Cabriolet

- 0-100 km/h: 6.1 s (6.2 s)

- 60-120 km/h: 5.7 s (6.7 s)

- NEDC consumption: 11.1 l/100 km (11.6 s)

For all CLK models with an automatic transmission Mercedes-Benz has developed a manual shift programme which allows particularly brisk gear changes using steering wheel buttons (optional equipment). The driver need not take his hand from the steering wheel but shifts the five or seven gears at the touch of a button. In automatic mode the shift programmes "C" (Comfort) and "S" (Sport) are available. In the "M" programme the gears are only shifted using the buttons or by operating the shift lever. From mid-2004 Mercedes-Benz is also upgrading the innovative technology of the CLK-Class with the option of a newly developed cornering light function which is available in conjunction with the powerful bi-xenon headlamps. When cornering, parking or negotiating tight bends up to a speed of 40 km/h, the left or right fog lamp is switched on and illuminates the frontal area beside the car to an angle of up to 65 degrees, with a range of approx. 30 metres.

From mid-2004 Mercedes-Benz is also upgrading the innovative technology of the CLK-Class with the option of a newly developed cornering light function which is available in conjunction with the powerful bi-xenon headlamps. When cornering, parking or negotiating tight bends up to a speed of 40 km/h, the left or right fog lamp is switched on and illuminates the frontal area beside the car to an angle of up to 65 degrees, with a range of approx. 30 metres.

Impression of quality: carefully improved exterior and interior details

An innovative clearcoat based on the latest nano-particle technology which significantly improves scratch-resistance and the sheen of the paint finish, as well as a leather-like grain on the interior surfaces, further enhance the appearance of the CLK-Class. In the interior Mercedes-Benz has replaced the previous switches in the centre console with new push-push switches and equipped the control panels for the THERMATIC and THERMOTRONIC climate control systems with attractive rotary controls which simplify the adjustment of the temperature, air distribution and fan speed, while at the same time enhancing the impression of quality in the interior even further.

CLK 55 AMG: newly developed composite brakes and sports exhaust system

Even the CLK 55 AMG, the sporty and exclusive high-performance model in the CLK-Class line-up, now offers extra sportiness: Coupé and Cabriolet come with an even more powerful braking system. Composite brakes with floating, internally ventilated grey cast iron discs with a diameter of 340 millimetres are fitted at the front axle. The brake discs are connected to an aluminium bowl and, together with the large surfaces of the linings in the six-piston fixed callipers, provide far better heat resistance. Meanwhile, 330-millimetre internally ventilated discs with four-piston fixed callipers provide the braking at the rear axle. The impressive AMG 5.5-litre V8 engine developing 270 kW/367 hp and 510 Newtonmetres of torque provides dynamic power delivery and now has an even sportier sound – thanks to the new AMG sports exhaust system with its two distinctive twin tailpipes (only Coupé). Modifications to the chassis and power transmission also provide a more intense driving experience: the firmer spring/ damper tuning and the seven per cent increase in direct steering ensure even better roadholding and far greater dynamic handling. The new AMG SPEEDSHIFT five-speed automatic transmission does not shift down in the manual transmission mode “M” under full throttle and kick-down. Once a certain engine speed ceiling is reached, the AMG SPEEDSHIFT does not automatically shift up to the next gear. This allows the driver with sporting ambitions can make even better use of the superlative performance potential of the CLK 55 AMG.

The impressive AMG 5.5-litre V8 engine developing 270 kW/367 hp and 510 Newtonmetres of torque provides dynamic power delivery and now has an even sportier sound – thanks to the new AMG sports exhaust system with its two distinctive twin tailpipes (only Coupé). Modifications to the chassis and power transmission also provide a more intense driving experience: the firmer spring/ damper tuning and the seven per cent increase in direct steering ensure even better roadholding and far greater dynamic handling. The new AMG SPEEDSHIFT five-speed automatic transmission does not shift down in the manual transmission mode “M” under full throttle and kick-down. Once a certain engine speed ceiling is reached, the AMG SPEEDSHIFT does not automatically shift up to the next gear. This allows the driver with sporting ambitions can make even better use of the superlative performance potential of the CLK 55 AMG.

-----

Engines and transmission

Mercedes-Benz has extended the six-cylinder line-up for the CLK Cabriolet by adding the tried-and-trusted 2.6-litre V6, which develops 125 kW/170 hp and provides a maximum torque of 240 Nm at 4500 rpm. The CLK 320 Cabriolet remains unchanged in the line-up. And with good reason: the V6 power plant (160 kW/218 hp) is particularly well-suited to the new Mercedes Cabriolet, since it delivers equally impressive performance during either sporty driving with high power output or more serene and relaxed driving at lower engine speeds. With 310 Nm of torque on tap from just 3000 rpm, the six-cylinder engine offers the very best of both worlds. The V6 and V8 engines are both classic Mercedes innovations that ensure low fuel consumption, low emissions and exemplary torque characteristics:

The V6 and V8 engines are both classic Mercedes innovations that ensure low fuel consumption, low emissions and exemplary torque characteristics:

- Three valves per cylinder, to optimise the in-cylinder gas cycle and combustion, as well as to ensure faster heating of the catalytic converter after a cold start.

- Phased dual ignition for precise and effective combustion.

- Cylinder liners made using aluminium and silicon, to reduce engine friction.

- State-of-the-art lightweight construction based on aluminium and die-cast magnesium, to reduce engine weight.

- Switchable intake module, to increase bottom-end torque and optimise power characteristics.

Four-cylinder engine: impressive power and smooth operation thanks to TWINPULSE system

The new generation of four-cylinder engines from Mercedes-Benz, launched in the spring of 2002, will also further optimise the CLK Cabriolet with respect to fuel economy, torque, power output and refinement.

This impressive performance is thanks to the unique TWINPULSE system which combines technical innovations such as a compressor supercharger, intercooler, four valves per cylinder, variable camshaft adjustment and Lanchester balancer.

The 120-kW/163-hp four-cylinder version beneath the bonnet of the CLK 200 KOMPRESSOR Cabriolet propels the two-door model from 0 to 100 km/h in 9.8 seconds, enabling it to reach a top speed of 225 km/h. The four-cylinder model completes the sprint from 60 to 120 km/h (in fifth gear) in 17.4 seconds. In terms of top speed, the new CLK Cabriolet is therefore seven km/h faster than the previous model. Fuel consumption has been reduced to 8.8 litres per 100 kilometres (NEDC combined consumption), 0.7 litres less than in the previous CLK 200 KOMPRESSOR.

Camshafts: variable adjustment depending on engine load

Made from a high-strength aluminium alloy, the cylinder head in the four-cylinder engines for the CLK 200 KOMPRESSOR Cabriolet has 16 valves and double overhead camshafts. Both camshafts have variable adjustment. A vane-type adjuster with an integrated control valve ensures optimum valve timing at all times. This has a positive effect on torque characteristics under full load as well as on fuel consumption and exhaust emissions.

The Mercedes engineers have reengineered the compressor – which ensures exemplary bottom-end torque characteristics – by reducing the clearance between the rotors and the supercharger housing and by using a new coating for the rotors. The result: an even higher rate of air flow and even better efficiency than in the mechanical supercharger used in previous Mercedes four-cylinder engines. After being compressed, the air exits the compressor and flows through an intercooler, thus reaching the optimum temperature and density for the combustion process.

Balancer shafts: decisive for ensuring refinement on a par with a six-cylinder engine

Alongside exemplary power delivery, low fuel consumption and low exhaust emissions, the new Mercedes four-cylinder engines have a further advantage, namely refinement and acoustics similar to a six-cylinder engine. This is primarily down to the Lanchester balancer which consists of two forged shafts supported in multiple bearings. The shafts counter-rotate at twice the crankshaft speed and, in so doing, compensate for the inertia forces which are caused by the motion of the pistons, for example, which tend to cause irritating vibrations.

Five-speed automatic: with Touchshift and two transmission modes

Standard equipment in CLK 200 KOMPRESSOR and CLK 240 Cabriolet models includes the sophisticated six-speed manual transmission which is ideally suited to the car's agile character thanks to its short shift travel. The Mercedes engineers have configured 6th gear as a real "driver's gear" in which top speed is reached. For drivers who demand even greater comfort and convenience, Mercedes-Benz offers the option of an electronically controlled five-speed automatic transmission with Touchshift. This comes as standard in the CLK 320 Cabriolet and CLK 500 Cabriolet models. With its modified control set-up, the Touchshift feature gives the driver even more options for engaging the ideal gear for the situation in hand. Holding the selector lever in the "–" or "+" position tells the transmission to keep moving down the ratios until the one that can best slow or accelerate the Cabriolet is found. When driving downhill, the driver thus has the convenient option of shifting down to obtain the best possible engine braking effect. In the same way, the ratio from which the vehicle derives optimum performance can be engaged when accelerating.

For drivers who demand even greater comfort and convenience, Mercedes-Benz offers the option of an electronically controlled five-speed automatic transmission with Touchshift. This comes as standard in the CLK 320 Cabriolet and CLK 500 Cabriolet models. With its modified control set-up, the Touchshift feature gives the driver even more options for engaging the ideal gear for the situation in hand. Holding the selector lever in the "–" or "+" position tells the transmission to keep moving down the ratios until the one that can best slow or accelerate the Cabriolet is found. When driving downhill, the driver thus has the convenient option of shifting down to obtain the best possible engine braking effect. In the same way, the ratio from which the vehicle derives optimum performance can be engaged when accelerating.

In addition, a new mode selector enables drivers to adapt the shift characteristics of the five-speed automatic to suit their individual driving style. There is a choice of "S" (Standard) or "C" (Comfort) mode. In Comfort mode the number of gear changes is reduced and, at lower road speeds, downshifts do not occur until later.

The Mercedes engineers have extended the operating time during which the torque converter lockup clutch is engaged, both to further improve vehicle agility when moving off and to reduce fuel consumption. In the case of the four-cylinder model, torque converter lockup is now possible in any gear – even first gear – whereas, before, it could only be engaged in third, fourth and fifth. Torque converter lockup reduces the slip that usually occurs between the pump and the turbine wheel, thereby improving mechanical efficiency and reducing fuel consumption.

-----

Chassis

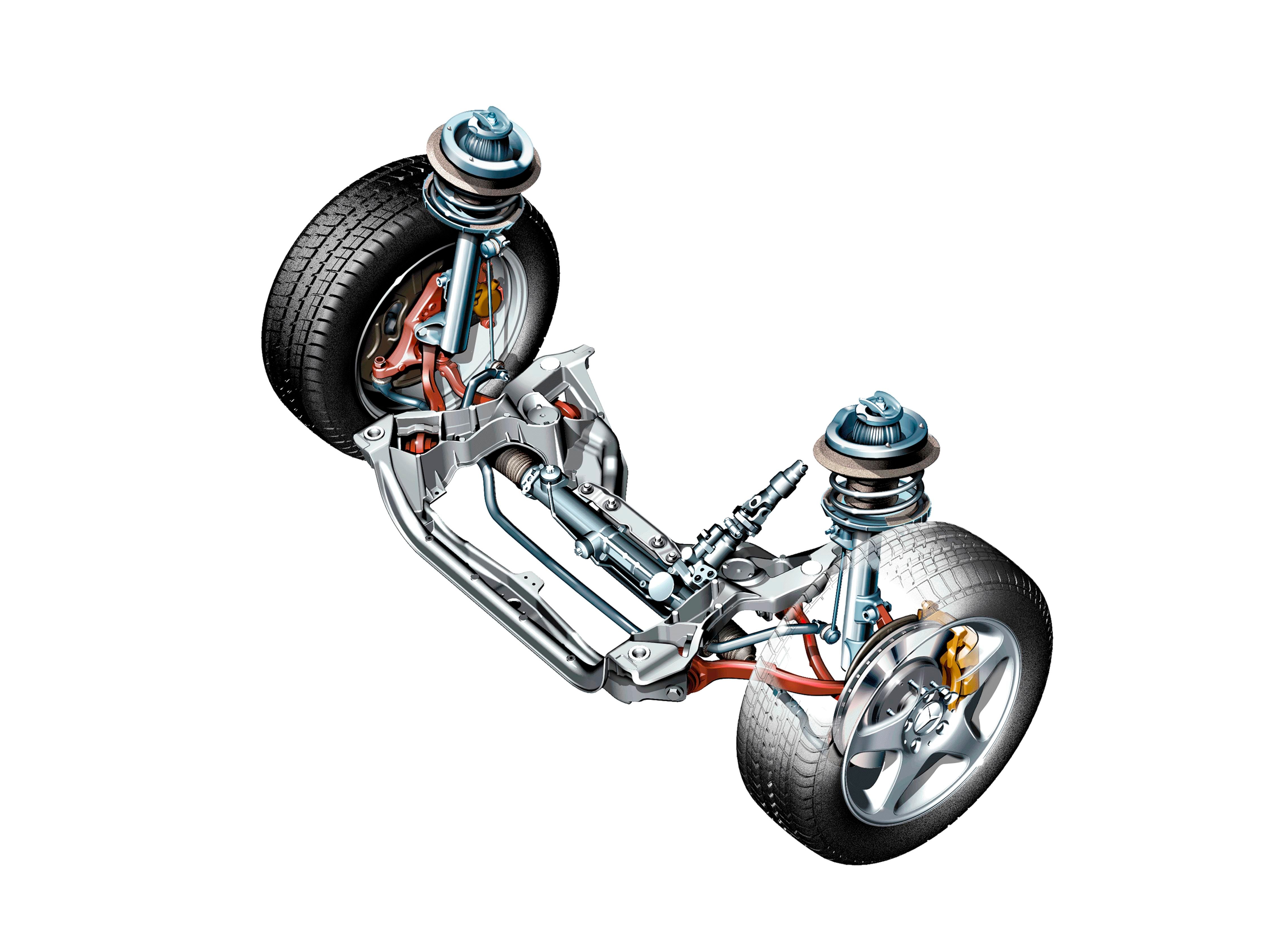

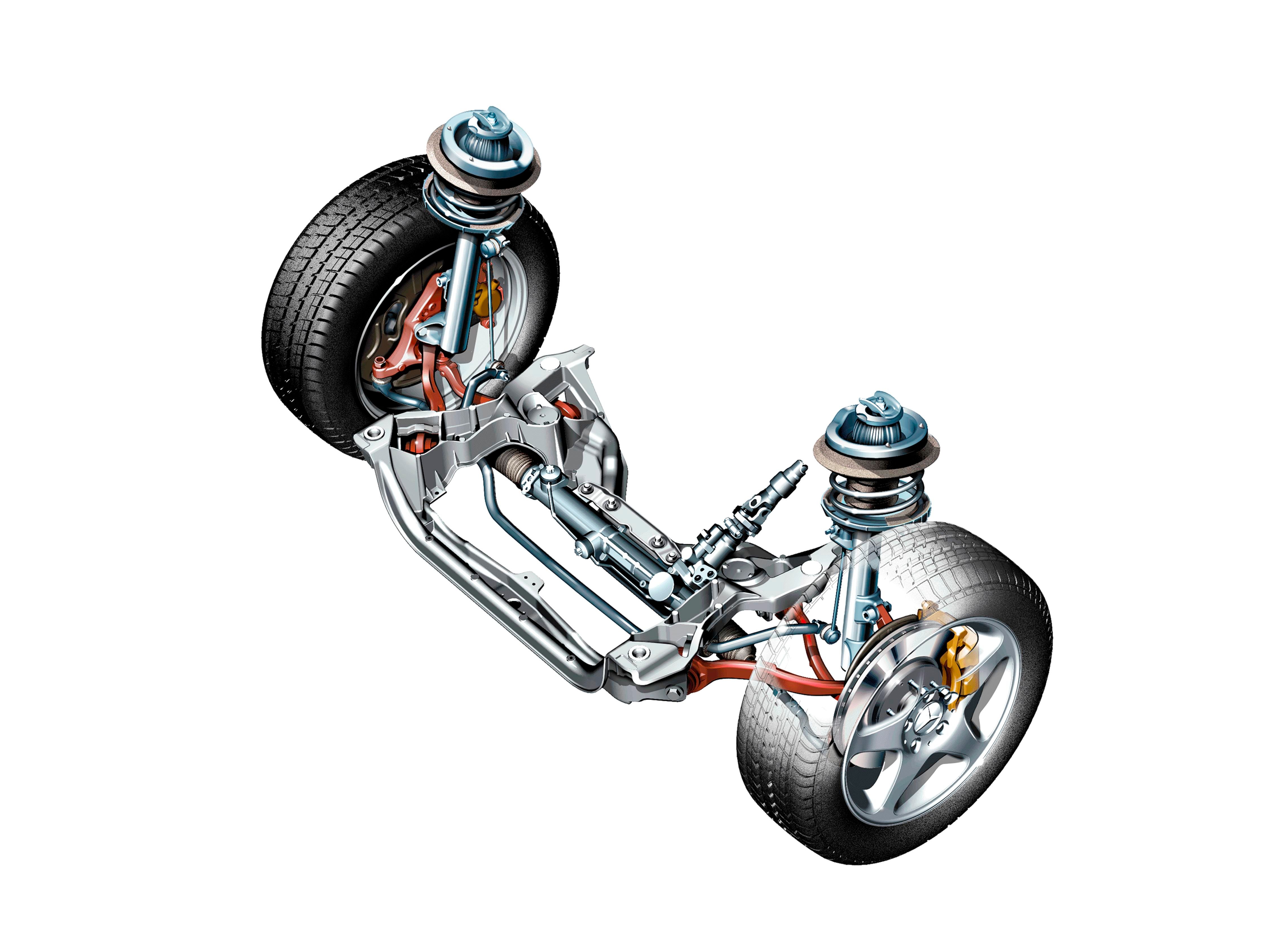

In terms of agility, straight-line stability, steering precision, road roar, tyre vibration and braking power – in short, practically all areas of chassis technology – the new CLK-Cabriolet achieves peak-performance figures which add up to ensure one thing above all: an even more dynamic driving experience.

The Mercedes engineers spared no expense in newly developing or modifying the axles, steering and brakes, to exceed the already high standards set by the predecessor model. In doing this, they were able to call upon tried-and-tested systems from the Stuttgart manufacturer's passenger car line-up and adapt these systems for use in the new Cabriolet. This involved the following:

- Replacing the previously installed double-wishbone design with state-of-the-art three-link front suspension with McPherson struts, thus enabling major advances, particularly with respect to wheel location, comfort and steering precision.

- The Mercedes engineers have replaced the previously fitted recirculating ball-type steering with power-assisted rack-and-pinion steering which is even more responsive and thus better suits the dynamic character of the new Cabriolet. Speed-sensitive power steering is available as an option (standard in the CLK 500).

- In conjunction with the newly developed front axle, the longer wheelbase and the standard-fitted Electronic Stability Program (ESP®), the tried-and-tested multi-link independent rear suspension ensures a high degree of active safety, dynamism and comfort. The track rods, hub carriers and subframe for the rear axle have also been radically reengineered by the Mercedes engineers in order to ensure even better vibration response.

Motorists who desire true sports performance can order the CLK Cabriolet chassis with tauter suspension and damper settings. Mercedes-Benz supplies this sports suspension set-up, in which the body is 15 mm lower at the front and rear axle, as an option for all lines and model versions. Spring rates for the sports suspension are up to five percent higher.

Brake system: new development with high power reserves

In terms of size, technology and equipment, Mercedes-Benz has tuned the brakes to each of the different engines and the wide range of outputs available with the new CLK Cabriolet. For instance, the flagship CLK 500 has 4-piston fixed-caliper disc brakes on the front axle, of the kind used for the SL 500 Roadster. The eight-cylinder model has 2-piston fixed-caliper disc brakes on the rear axle. The diameters of the internally ventilated front and rear brake discs are 345 and 300 mm respectively.

The technology used for the tandem brake booster (7/8-inch) made of aluminium is lifted from the S-Class. It is equipped with an electronically controlled solenoid valve that enables particularly precise application of the brake pressure. The main brake cylinder – also made of aluminium – is fitted with a pretensioned compression spring between the primary and secondary pistons. In contrast to conventional systems, in which the secondary piston only moves due to the pressure in the primary circuit, both brake circuits are activated simultaneously in the new CLK-Class Cabriolet. Substantially shorter pedal travel is just one of the benefits of this immediately obvious to the driver.

Active safety systems: ESP®, ASR, ABS and Brake Assist as standard

As is the case with all state-of-the-art Mercedes passenger cars, the new CLK Cabriolet is equipped with some of the best and most highly effective active safety systems available – as standard. Such systems include the Electronic Stability Program (ESP®), Anti-lock Brake System (ABS), Acceleration Skid Control (ASR) and Brake Assist. They reduce the risk of skidding when cornering, hold the Cabriolet safely on track when braking, improve starting on slippery surfaces and shorten the emergency-stopping distance.

This high-performance technology is an important part of the Mercedes-Benz safety concept and actively helps to prevent road accidents.

Wheels: light-alloy wheels and 16-inch wide-base tyres

Further special features of the new Mercedes Cabriolet designed to further enhance its sporty nature include different-sized tyres on the front and rear axles. The standard equipment package includes size 205/55 R 16 tyres on the front axle and 225/50 R 16 tyres at the rear. The top-of-the-range V8 CLK 500 model has 17-inch tyres, namely size 225/45 R 17 at the front and 245/40 R 17 at the rear. The design of the standard-fitted light-alloy wheels has been adapted to suit the individual character of each line: the ELEGANCE model is fitted with smart seven-hole rims, whilst the AVANTGARDE line comes with a distinctly sporty five-spoke-rim look that makes it really stand out.

Optional equipment for all model versions includes special 17-inch light-alloy wheels or 18-inch AMG light-alloy wheels.

Further standard equipment for the new CLK Cabriolet includes the innovative TIREFIT repair kit in place of the conventional spare wheel. The spare wheel recess in the boot can therefore be used as a stowage compartment. Mercedes-Benz still supplies the spare wheel as a no-cost option.

-----

Safety

Like the Coupé, the new CLK-Class Cabriolet incorporates the pioneering and practical Mercedes safety concept. This concept also takes into account occupant protection in the frequent collisions that occur at mid-range speeds. For instance, in the event of a frontal impact, a three-stage protection system is activated, based on the severity of the collision:

- At impact speeds of up to 4 km/h, the foam elements in the bumper absorb the crash energy, thus ensuring that the panels behind remain undamaged. The plastic bumpers even revert to their original shape after the accident.

- At impact speeds of around 15 km/h, the energy is absorbed within the newly developed front module and its integrated crash boxes made of highly-resistant steel.

- At crash speeds in excess of 15 km/h, the impact forces are channelled into four independent zones:

- via the aluminium crossmember in the front module, which channels the impact force to the side of the vehicle unaffected by the collision;

- via the substantially forwards-extended side members (behind the crash boxes);

- via robust sectional panels above the wheel housings, which provide an additional path for channelling the impact forces;

- via the front wheels which are supported by special crash elements in front of the side members (doorsills), enabling them to channel the impact forces into the body side structure.

Bulkhead: highly-resistant and vital for occupant protection

The front end is connected to the passenger cell by means of an ellipsoid bulkhead comprising several panels of differing thickness. This set-up enables the material to be adapted according to the severity of the impact and represents an ideal compromise between lightweight design and crash safety. The thickness of the high-strength steel varies by up to 150 percent, meaning that the bulkhead is not only capable of withstanding extreme loads, it can also evenly disperse the forces generated by a frontal collision over a wide area. This prevents dangerous intrusions into the passenger cell. Consequently the previously installed front side member extensions are no longer required.

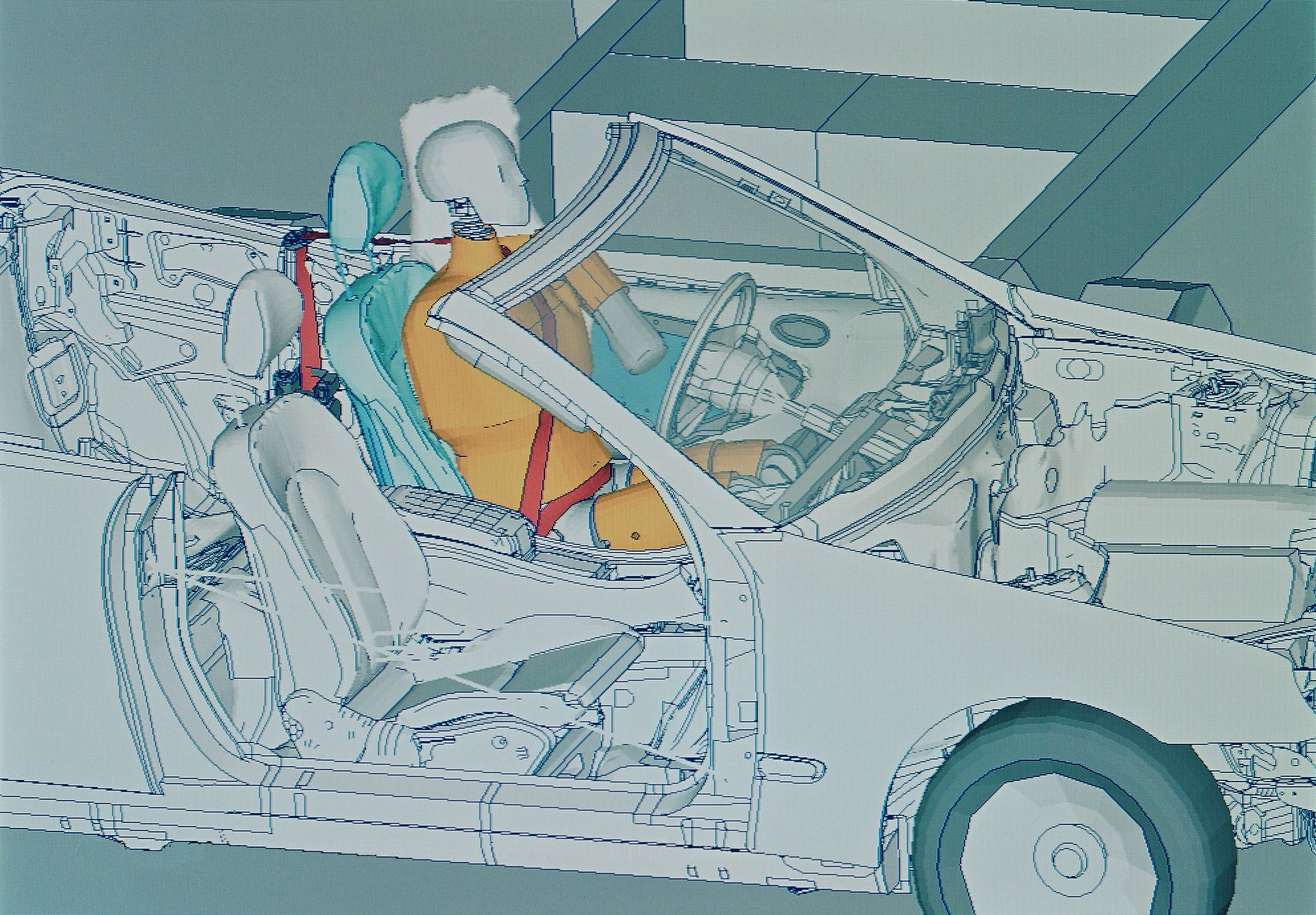

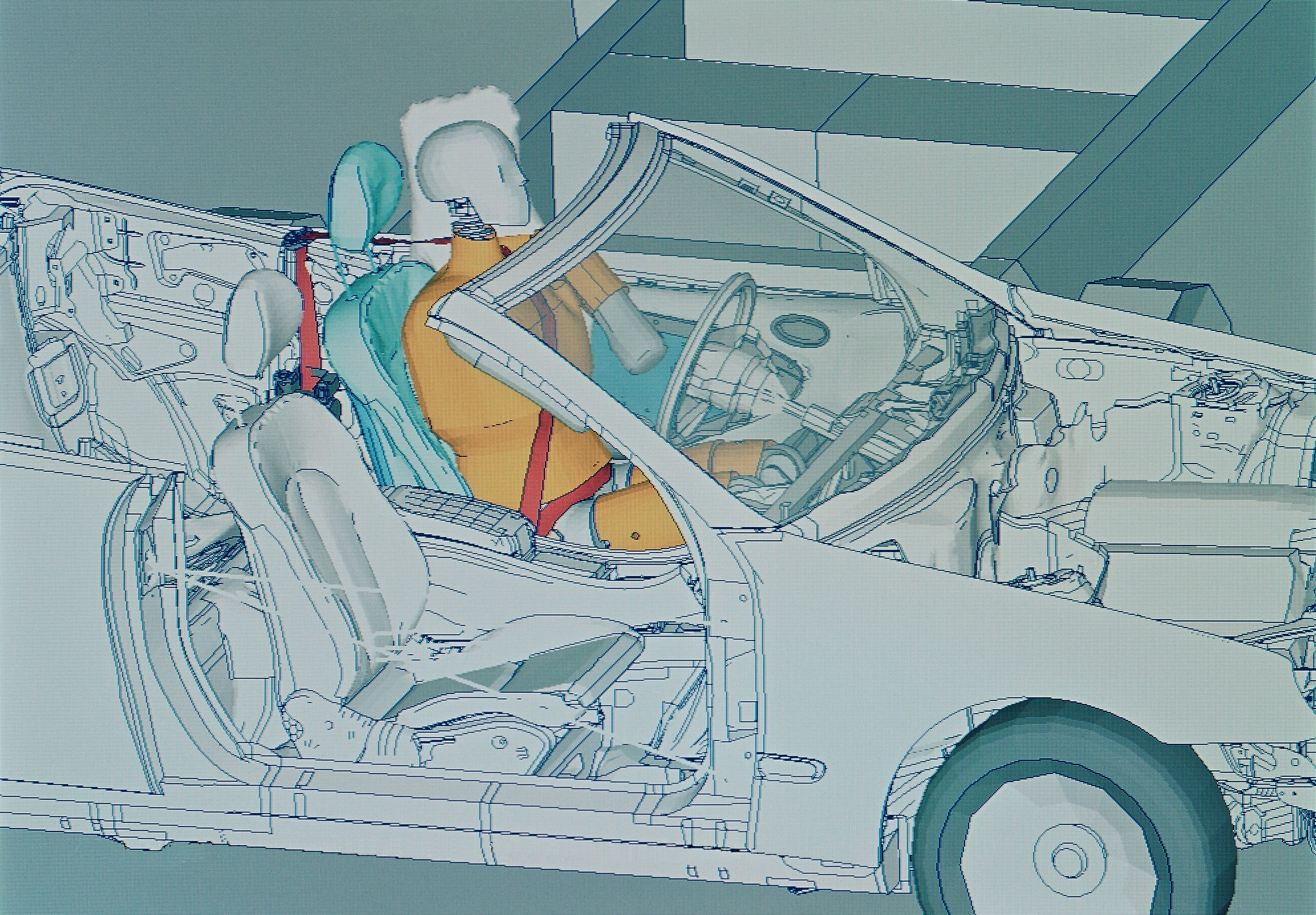

Front airbags: two-stage deployment based on impact severity

Adaptive front airbags – airbags that adapt according to the type of collision and deploy in two stages depending on the severity of the collision – prove the perfect complement to the practical occupant protection concept in the new CLK Cabriolet:

- Stage 1: in the event of a minor frontal collision, the ECU only fires one stage of the two-stage airbag gas generators. The airbags are therefore inflated to a lower pressure.

- Stage 2: if the control module detects a severe frontal collision, it also activates the second stage of the gas generators, after a delay of between 5 and 15 milliseconds. The airbags are thus inflated to a higher pressure, offering the occupants a level of protection in line with the severity of the accident.

The body weight of the front-seat passenger is also taken into account when the front passenger airbag is deployed. The airbag can then, for example, trigger both generator stages even in low-impact collisions in order to offer heavier front passengers an ideal level of protection. The second airbag stage is only deployed for lighter passengers, on the other hand, once a higher severity threshold is reached. At the same time, the newly developed system acts as a seat occupancy sensor and ensures that the front passenger airbag, belt tensioner and head/thorax bag are deactivated if the seat is unoccupied. Automatic child seat recognition is also part of the standard specification for the CLK Cabriolet.

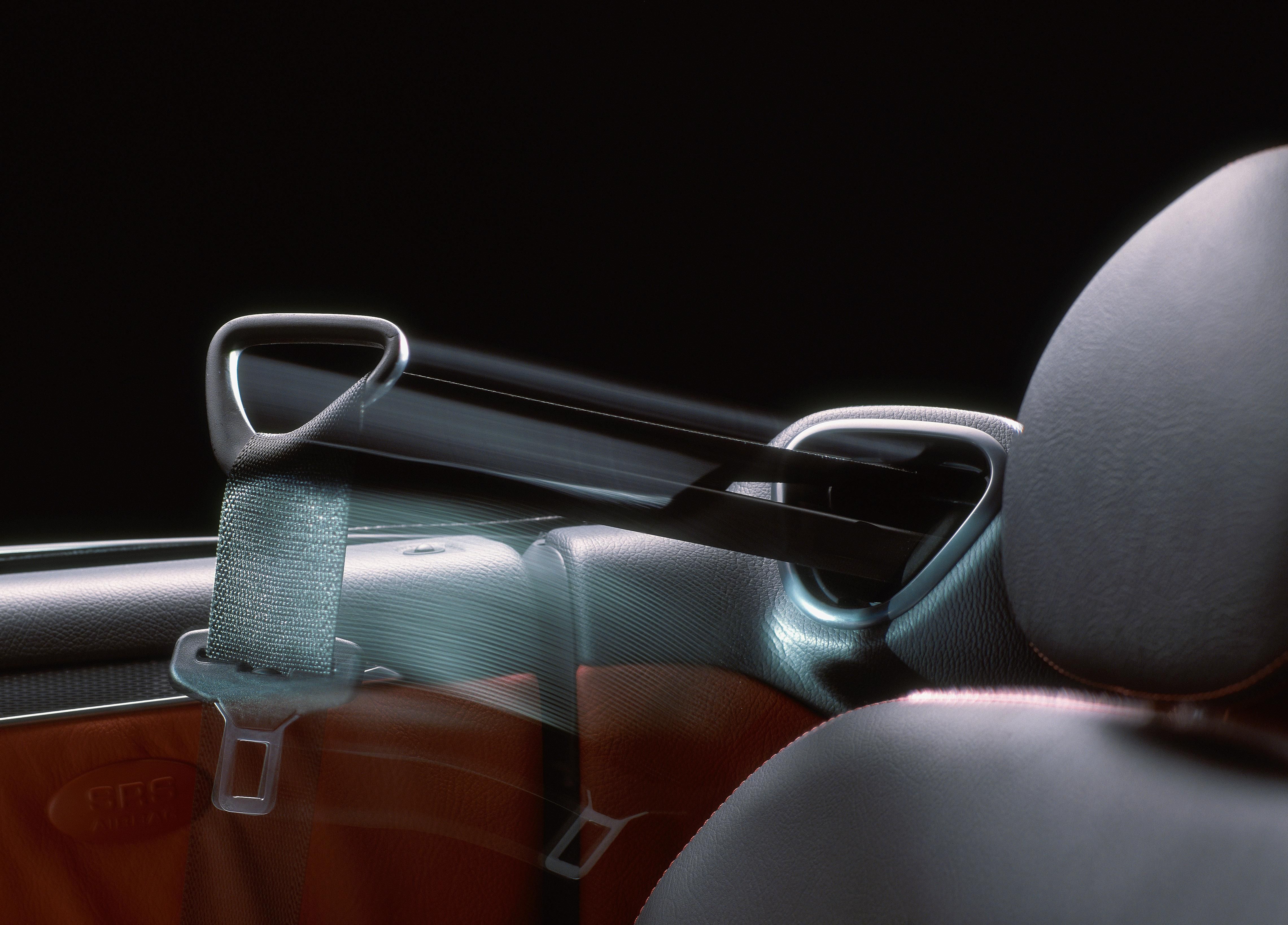

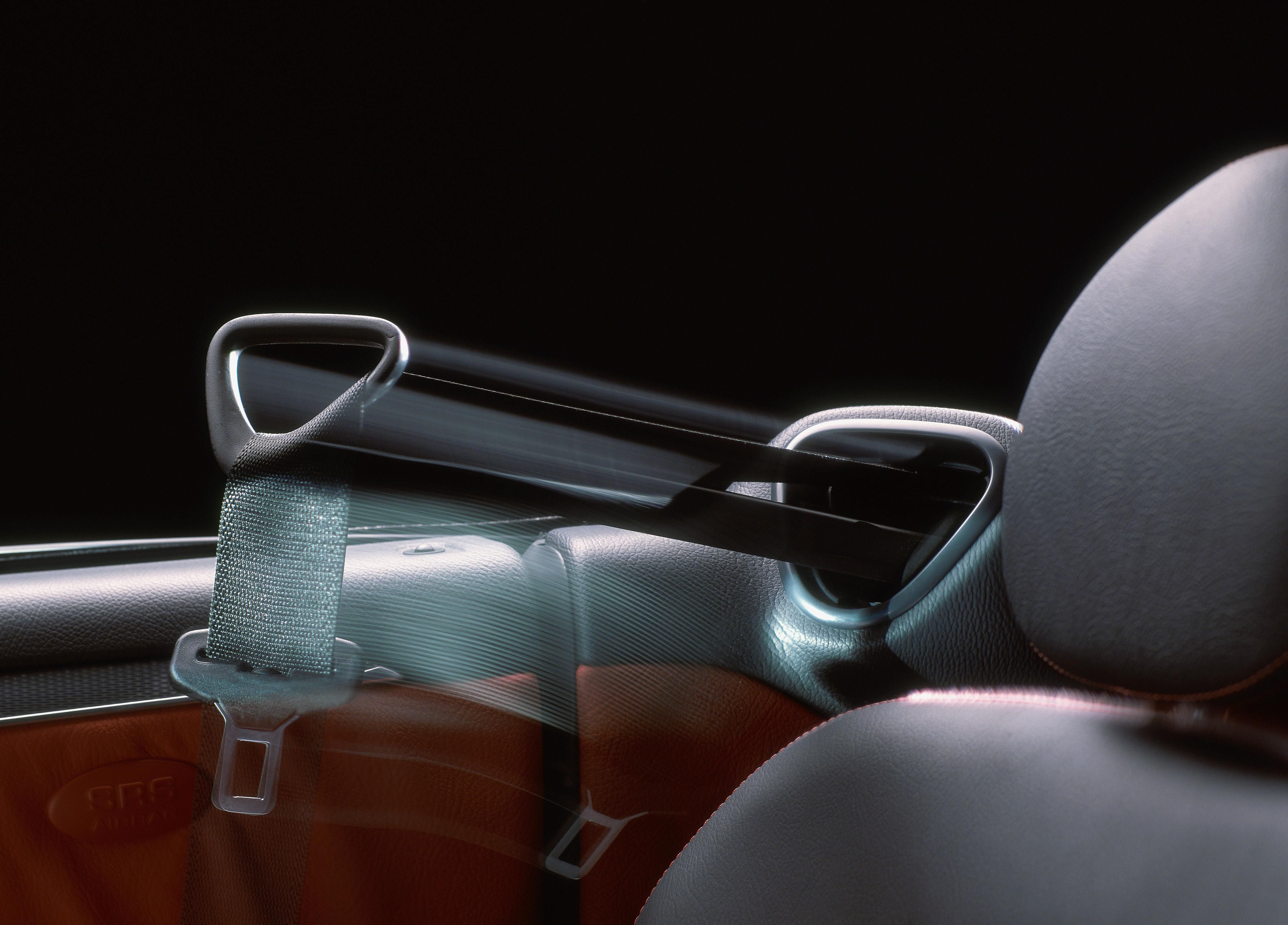

Belt feeders: added convenience for driver and front passenger

The automatic belt feeder is a further piece of unique technology used by the Mercedes engineers. It assists the driver and front passenger when putting on the automatic three-point seat belts. As soon as the occupants are seated and the ignition has been switched on, an electric motor extends the plastic rods holding the buckles on both sides of the vehicle so that the belts can be conveniently reached. The belt feeders retract again once the seat belts are fitted.

Head/thorax bags: 20-millisecond deployment following a side impact

Analyses performed by Mercedes accident researchers show that airbags can also perform an important protective function in the event of a side impact. This is why, in 1995, the Sindelfingen engineers invented the sidebag – integrated in the door and primarily designed to offer protection in the thorax area – followed three years later by the windowbag, which offers additional head protection and is housed on the inside of the roof frame.

However, this tried-and-trusted combination is not compatible with the design of a cabriolet; therefore, Mercedes-Benz developed a side airbag that protects both the head and the upper body, called the head/thorax bag. It is located in the front seat backrest and deploys within just 20 milliseconds in the event of a lateral impact. Once deployed, the airbag assumes an asymmetric shape, the top of which is higher than the top of a conventional sidebag when fully inflated. The head/thorax bag therefore reduces the risk of the head colliding with the side window or with objects that penetrate the vehicle interior, regardless of the occupant's sitting position.

The lower section of the head/thorax bag inflates between the door and the occupant in the event of a lateral impact or roll-over, so as to also provide extensive protection in the chest area. This newly developed side airbag has a capacity of around 15 litres. Sidebags for the rear passengers are being offered as an option in a Mercedes cabriolet for the first time. They are housed behind the side panels, above the side armrests, and are designed to offer rear occupants greater protection in the thorax area in the event of a severe side impact.

Roll-over protection: automatic activation if a crash is imminent

Mercedes-Benz takes the issue of roll-over protection very seriously indeed when developing open-top cars. Even the 300 CE-24 Cabriolet – the first four-seater cabriolet from model series 124 to be unveiled back in September 1991 – was equipped with automatic roll-over protection that was activated by sensor control whenever roll-over was imminent. This multi-award-winning system was an ingenious solution as it successfully combined the high safety standards typical of Mercedes-Benz with a desire held by many cabriolet drivers: unbridled open-air driving pleasure with an attractive (i.e. bar-less) exterior design.

The new CLK-Class Cabriolet features a similar roll-over protection system, in which a tilting cone sensor detects imminent danger to the occupants – based on extreme sliding movements or high levels of acceleration caused by a collision – and activates the automatic roll-over protection within milliseconds, regardless of whether the soft-top is up or down. The protective system is therefore activated as a precaution in the event of a frontal, lateral or rear collision, just in case the collision results in the car rolling over. The roll-over protection system consists of two robust bars, each measuring 35 millimetres in diameter, which are housed in enclosed units behind the rear seat backrest together with the rear head restraints. When the sensor transmits a crash signal, a solenoid activates pretensioned pressure springs which extend both roll-over bars and the rear head restraints at the same time. They reach their highest position after a maximum of 0.3 seconds and are then locked automatically. The steel bars act in conjunction with the robust, tubing-reinforced A-pillars to provide reliable roll-over protection.

The roll-over protection system consists of two robust bars, each measuring 35 millimetres in diameter, which are housed in enclosed units behind the rear seat backrest together with the rear head restraints. When the sensor transmits a crash signal, a solenoid activates pretensioned pressure springs which extend both roll-over bars and the rear head restraints at the same time. They reach their highest position after a maximum of 0.3 seconds and are then locked automatically. The steel bars act in conjunction with the robust, tubing-reinforced A-pillars to provide reliable roll-over protection.

In this newly developed system, the rear head restraints and roll-over bars are separate entities – they only operate and extend together in the event of danger. Under normal driving conditions, the height of the rear head restraints can be adjusted individually by hand; if the rear head restraints are not required, a push of the button on the dashboard is all that is needed to lower them. The rear head restraints are also lowered automatically when the soft-top is opening or closing, in order to free up space for the fabric top.

-----

Technical Specifications

Mercedes-Benz CLK240

Engine

Performance and fuel consumption

Mercedes-Benz CLK320

Engine

Performance and fuel consumption

Mercedes-Benz CLK500

Engine

Performance and fuel consumption