With automakers such as Tesla->ke1842 already selling reliable, fast, and quick-charging electric vehicles, and numerous companies moving closer to launching mass produced hydrogen cars,->ke4485 the industry makes small but firm steps toward phasing out fossil fuels. Sure, it won't happen anytime soon, but the number of gasoline and diesel powered vehicles->ke1917 could decrease dramatically in a couple of decades. This a scenario that frightens many gas companies, including Shell, which has just unveiled a concept car that aims to prove fossil fuels can still be used efficiently with backing from the right technology.->ke1701

Developed from Gordon Murray's (yes, it's the same man that designed the bonkers McLaren F1)->ke1159 T25 city car of 2010, Shell's microcar revives the "bubble car" concept->ke169 of the 1950s. It's small and light as a feather, but unlike the BMW Isetta, it was built using modern materials and promises to return outstanding fuel economy.

Although the vehicle is still in its conceptual phase and plans for a production model have yet to be revealed, Shell believes that its new microcar will revolutionize transportation.

"This is a significant automobile engineering milestone. I’m very proud of what Shell’s scientists and their partners at Geo Technology and Gordon Murray Design have achieved. Insights gained from this project could be transformational in terms of how we address energy use in the road transport sector. Energy use and climate change are major issues for society. This project shows that if we use the best of today’s technology, including cutting edge lubricants science, we could potentially have a major impact on energy use and reduce CO2 emissions," said Mark Gainsborough, executive vice president of Shell.

It remains to be seen whether Shell's concept car will make it into production and make an impact on the industry, but until the oil company releases further details, we will have a closer look at what we already know about this modern Isetta.

Continue reading to learn more about the Shell Concept Car.

2016 Shell Concept Car

- Make: Array

- Model: 2016 Shell Concept Car

- Engine/Motor: inline-3

- Horsepower: 43

- [do not use] Vehicle Model: Array

Exterior

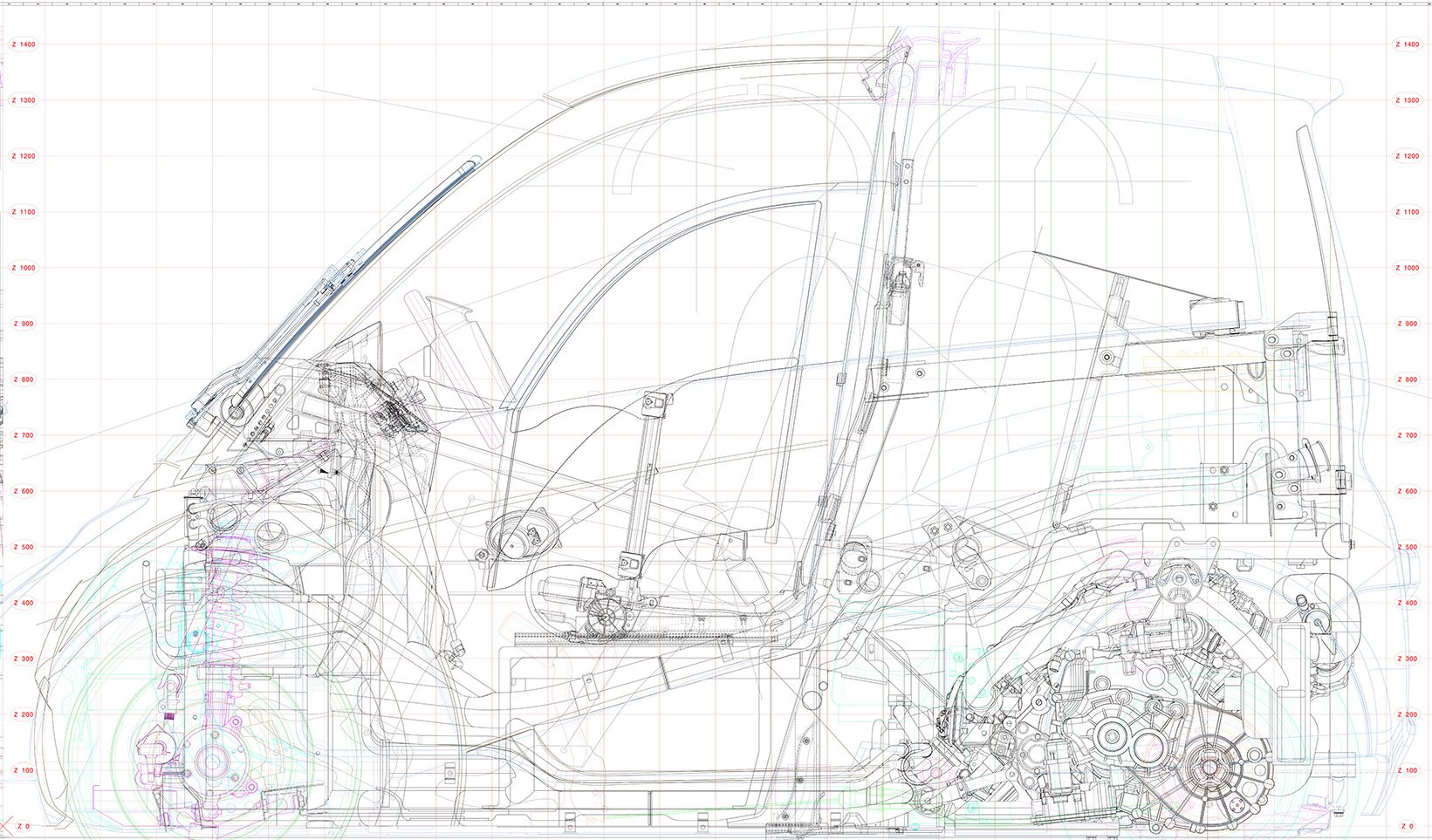

Design-wise, Shell's microcar is obviously an evolution of Gordon Murray's T.25 design. The overall shape and size are similar, but the new vehicle was redesigned aerodynamically in order to reduce drag as much as possible. The front fascia has smooth, rounded contours and the headlamps are completely integrated into the body. The wheels are covered by aerodynamic caps usually seen on cars attempting speed records at the Bonneville Salt Flats, while the conventional side mirrors have been replaced by cameras. The rear wheels are hidden underneath the fenders, also to reduce drag.

All told, Shell's new concept is a new take on the "tall and narrow" look introduced by 1950s microcars and adopted by Japanese kei cars in the 1980s, but much to Murray's credit, it's far from ugly for a vehicle that was designed with aerodynamics in mind.

Styling aside, the Shell Concept Car is as modern as they get as far as construction goes. The body is made from recycled carbon-fiber, which means it can be assembled for a quarter of the price of a conventional steel vehicle, while many components were created using 3D printing. It's also very light, tipping the scales at only 550 kg (1,213 pounds). What's more, the entire car can be fully recycled at the end of its life, which can't be said about most products on the market today.

Interior

Despite its diminutive exterior, the Shell Concept Car can provide seating for three people thanks to its seating arrangement with the driver in the center of the cockpit and two passenger seats behind. If this layout sounds familiar, it's because it's the same Gordon Murray introduced it in the McLaren F1 supercar in 1992.

The interior is obviously simple by design with a tiny dashboard and a handful of buttons and switches at the driver's disposal. Behind the three-spoke steering wheel lies a display using a modified version of Shell’s Drive App, which provides the driver with real time information on the vehicles performance and fuel efficiency. The main screen is flanked by two smaller displays that receive images from the cameras that act as side mirrors.

The lower section of the cockpit is made from exposed carbon-fiber, a feature that will probably make the production model pretty expensive unless the lightweight material doesn't become cheaper in the near future.

Not surprisingly, given the car's exterior dimensions, the cabin looks cramped and rather uncomfortable for long drives. That shouldn't be an issue though, as Shell's microcar isn't the kind of vehicle you'd spend a lot of time in, especially since it has no actual trunk. I guess there is enough room for some groceries if you go shopping with just one passenger in the rear seats.

Drivetrain

The Shell microcar gets its juice from a tiny three-cylinder gasoline engine that produces 43 horsepower. The company doesn't provide many details about the powerplant, but it's probably related to the unit Gordon Murray built for the T.25. The three-pot is mounted behind the seats and moves the vehicle from 0 to 62 in 15.8 seconds and up to a top speed of 70 mph. Granted, that's far from impressive, but this car wasn't built with performance in mind. It's the fuel economy department that's supposed to be impressed with a consumption of 89.1 U.S. mpg (107 U.K. mpg / 2.64 liters per 100 km). Carbon-dioxide emissions are rated at 4.67 grams per km, which is significantly lower than typical petrol-powered city cars and hybrid vehicles. These figures were achieved at speeds of 45 mph and with bespoke lubricants provided by Shell.

The gas company says it used a bespoke engine oil based on its Helix Ultra with PurePlus Technology that minimizes friction within the engine. The special oil reportedly reduced CO2 emissions by 7.1 percent, but Shell doesn't say what impact it had on fuel economy. The three-cylinder engine also received special attention, with Geo Technology optimizing it by redesigning many of the components associated with friction.

So, is Shell's 89-mpg fuel economy as impressive as the company's wants it to sound? Well, it really depends on what you compare it with. The new Smart ForTwo, for instance, returns up to 39 mpg, which makes this microcar quite the deal. On the other hand, the Volkswagen XL1, a hybrid using a three-cylinder turbodiesel and an electric motor, is said to return up to 260 mpg when using both sources and up to 120 mpg on diesel power alone. It's probably not best example given the recent Dieselgate scandal, but it's proof that hybrids can be significantly more efficient than the most energy-saving gasoline engine ever built.

Conclusion

The Shell Concept Car is a daring project in an era where most automakers are looking to improve their fuel economy and reduce carbon footprint by developing electric, hybrid, and hydrogen cars. It might seem like a desperate attempt from an oil company to keep fossil fuel alive, but the fact that Shell worked with Gordon Murray and integrated a few innovative ideas into the concept gives it some credibility. Granted, the concept looks good on paper and its 89-mpg rating is nothing to sneeze at, but Shell's microcar won't matter unless it is followed by a an equally efficient production car with an affordable price tag. With performance-oriented EVs like the Tesla Model 3 set to cost less than $30,000 after incentives, a gasoline-powered microcar that costs more than $10,000 is doomed to fail no matter how much carbon-fiber it has in its body.