How do they work? What are the differences between them? Which is better and why? Because we’ve been asked these questions only a gazillion times, we figured we might as well put this down in writing. Giving someone a link is much easier than explaining it over and over again. So here goes…

Both Superchargers and Turbochargers have their fans (no pun intended) and the following should give you an indication why. Let’s start with the basics. Both superchargers and turbos belong to the forced induction family, meaning they force more air into an engine. Ramming in more air means you can add more fuel. More air and fuel means a bigger bang and hence more power - simple. They have their fundamental differences which we will explore later, but essentially do the same thing. Before going any further let’s get one thing straight, neither is actually better than the other. What it basically comes down to is what you are trying to achieve, what your budget is, and which works better for your intended application.

Check out the full explanation after the jump.

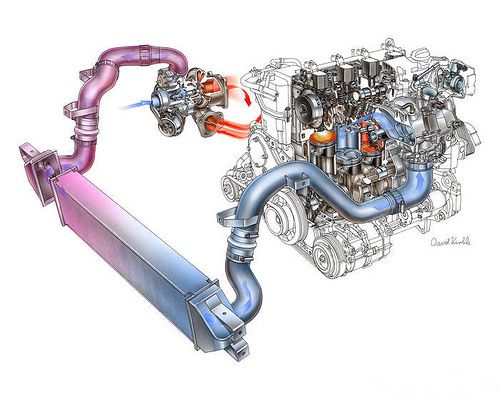

How a Turbocharger Works

The beautiful device known as a turbocharger is bolted on to a set of custom headers and uses exhaust gases to spool one of two impellors linked by a shaft inside the turbo. The other impellor in turn, sucks air into the engine, generating the addictive phenomenon known as boost. Because the turbo is fed by exhaust gas, immense heat is generated, facilitating the need for an intercooler. An intercooler looks and functions like a radiator except that it doesn’t contain water. Instead the hot “boosted” air travels through it and is cooled along the way. This means the turbo system is not very thermally efficient and if temperatures are not kept in check, could cause damage to your engine. Ever heard of “turbo lag”? If you haven’t, it's one of the pet peeves of driving a turbocharged car. As mentioned earlier, turbo systems use the exhaust gases to drive the turbo, and lag is the time it takes the exhaust fumes to turn the turbo impellor. Once the impellor is spooled up though, you will reach full boost very quickly. In a real world driving scenario, this equates to poor response at a low RPM. Smash your right foot to the floor at around 2000 RPM and nothing happens (depending on turbo and engine size). As the revs climb and more exhaust gas is generated, and the power comes in suddenly, creating that rush that make turbo cars so addictive and fun to drive. Although all turbos are the same, they have one variance – the bearings inside them.

Ball Bearing Vs Non-Ball Bearing

The philosophy here is straightforward. Things roll easier then they slide, meaning that new generation ball bearing turbos spool up much quicker than conventional bearing turbos, and also have the ability to spin much faster – around 250 000 RPM! Investing in a ball bearing setup means that you should have less lag and the ability to make more power for longer.

How a Supercharger Works

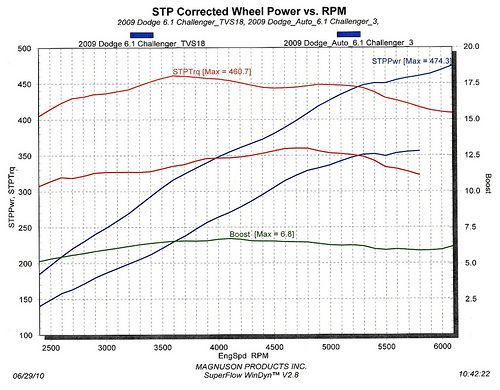

The supercharger, unlike the turbo, is driven by a belt, just like your alternator, which means it snaps some power from the engine in order to generate boost. This is accepted as a small price to pay for the ultimate overall HP gain. Because of this fact, superchargers are better suited to bigger engines (6 cylinder upwards). A big plus of a supercharger system is that it is not exposed to the heat issues of the turbo, and does not require the use of an intercooler. A same size turbo will make more peak HP than the supercharger due to the power lost to actually turn the supercharger over. In extreme cases, like NHRA Top Alcohol dragsters, the V8 engine itself needs to make a staggering 1000HP just to turn the supercharger over! Where turbos spin at around 250,000 RPM, superchargers typically spin at between 10,000-20 ,00 RPM, making them less susceptible to wear and tear. There might only be one kind of turbocharger, but there are 3 main variations of superchargers: centrifugal, screw type, and roots.

Centrifugal Type

A centrifugal ‘charger looks a lot like a turbo and has similar characteristics. Since the belts drive the supercharger they are usually working all the time. A centrifugal supercharger starts building boost in the lower RPM range and gradually gets to full boost at redline. To give you an example, if you have a 10psi system, you will start seeing 2psi around 2500 RPM and then 10psi at your redline. They are pretty efficient, but because they build boost with RPM, power delivery feels progressive – almost like a strong aspirated motor. These are widely used on aftermarket applications on import vehicles.

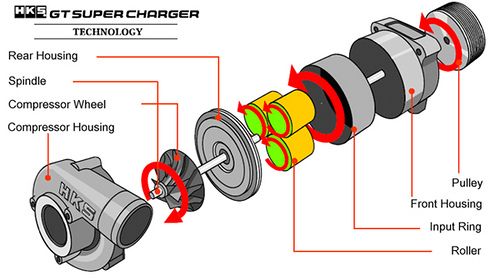

Screw Type

A twin-screw type supercharger offers great bottom end HP, torque, and response, because, unlike the centrifugal type, these generate full boost in the lower RPM range and deliver linear power throughout the entire RPM range. These are usually great for track racing because of the in-gear acceleration ability. This also makes them very useful in the real world when it comes to towing and overtaking. The twin-screw is the most versatile of the superchargers, suiting high and low boost applications just as well, and is very efficient thermally as well as in its power delivery. It is pretty much the supercharger type to have. These are commonly fitted to AMG Mercedes’.

Roots Type

The roots type is the oldest kind of supercharger there is. The technology dates back over 100 hundred years and it's key feature is it’s simplicity of design and operation. It has very few moving parts in relation to its cousins, the centrifugal and screw types. It works very much the same way as the screw type and offers great boost from very low down in the rev range, and is able to sustain that throughout. The only downside is that it’s the least efficient of the superchargers as it generates a lot of heat. In higher boost applications (more than 8 psi), it will require the use of an intercooler a la the turbo setup. They are still used on smaller engines requiring small boost, like the Toyota MR2.

Now that you have an idea as to the differences between the two, let's take a quick look at the tuneability of both systems and the costs involved.

Flexibility

There is no doubt that a supercharger system is cheaper and easier to tune. The ease of setup comes with the fact that the supercharger behaves in a progressive, predictable way, whereas a turbocharger boosts relatively unpredictably. That requires the tuner to be able to add lots of fuel very quickly to accommodate the turbo boost and prevent engine knock. Another major difference is the way boost is controlled. Since a supercharger is run off of the belt system, usually you have to change the size of the pulley to get more boost out of it. A larger crank pulley or smaller supercharger pulley achieve the same outcome of spinning the supercharger faster, generating more boost. One of the benefits of this setup is that you do not have to worry about over boosting your engine, as the system has fixed pressure levels. On the other hand, the turbo system is flexible to offer multiple boost settings, albeit each setting needing a custom “map” or tune. This brings us to the next point: regulating turbo pressure levels.

With a turbo you need a wastegate and a boost controller that controls the amount of boost you will get. All you have to do is turn the setting higher on the boost controller and you can change the boost pressure instantly. The convenience factor is there, however the draw back is over boosting the engine in the quest for more power!

Turbo systems are expensive because of the upgrades required to maintain reliability. Usually an intercooler, boost controller, turbo timer, and a wastegate are needed. On top of that you usually have to worry about the fuel components and all-important tuning. Regardless of what Forced Induction system you go for, they will both no doubt put a smile on your face and a stripe in your underwear every time you hit the throttle!

Here’s to reliable big HP gains courtesy of TopSpeed.