Infiniti just debuted the QX50 crossover concept at the 2017 Detroit Auto Show last week, and in case you didn’t get the memo, it’s a mid-size SUV with sleek styling and a few interesting autonomous driving tricks. However, one of the most interesting features is its engine, which Infiniti touts as an internal-combustion lump with turbocharging and variable compression – that is, the compression ratio can change while the engine is in use. Variable compression is a technology that many have sought to perfect, but Infiniti is the first to claim a production-ready iteration destined for dealerships. The benefits include that idealistic combination of high efficiency matched with high power levels, and in fact, the Japanese automaker boasts the engine will be able to offer the fuel economy of a hybrid four-cylinder, as well as the power output of a modern V-6. Sounds like the usual concept smoke and mirrors, doesn’t it? Well, believe it or not, variable compression just might be coming to a crossover near you.

Infiniti calls its forthcoming engine the VC-Turbo (Variable Compression Turbo), and despite the relatively uncreative name, the VC-Turbo is getting a lot of interest from car geeks the world over. And why not – the pressure is on to extract as much energy as possible from every last drop of gasoline, and technology like this promises to do just that without neutering performance.

But what is variable compression exactly, and how does it work? And more importantly, should we even care? Read on to find out.

Continue reading for the full story.

What Is It?

A Little Background

The idea of an internal combustion engine with variable compression dates back a long time, with the first example coming from British engineer Harry Ricardo in the ‘20s. Since then, several prominent automakers have taken a crack at it, including Volvo, Peugeot-Citroen, Lotus, Renault, and Saab, but so far, none have had much success.

We first heard Infiniti talking about its VC-T engine this past August, at which time the automaker announced that after more than 20 years in development, it was ready to give the world it’s first production-ready variable-compression engine.

As a follow up, Infiniti debuted the QX Sport Inspiration Concept at the 2016 Paris Motor Show in September, outfitting the mid-size concept with a turbo 2.0-liter gasoline four-banger and variable compression. Peak output was rated at 268 horsepower and 287 pound-feet of torque, thanks to a compression ratio that could infinitely vary between 8:1 and 14:1.

What Is Compression Ratio Again?

You probably hear the term all the time, but not everyone is familiar with what compression ratio actually is.

Basically, compression ratio is the ratio of volumes in an engine cylinder as determined by the position of the piston. As the piston moves up and down inside the cylinder, the amount of space between the top of the piston and the top of the cylinder (a.k.a. the combustion chamber) changes. The compression ratio is the ratio of the volume in the cylinder when the piston is at its lowest point (that is, when the volume is the greatest), and when the piston is at its highest point (or when the volume is the lowest. You put the big volume over the low volume, and voila – you’ve got your compression ratio.

So Why Does The Compression Ratio Matter?

This number is important for a number of reasons. Broadly speaking, the higher the compression ratio, the greater the engine’s thermal efficiency (that is, the more mpg you get).

So why not run the highest compression ratio possible all the time? Well, when you squeeze your air/fuel mix with a high compression ratio, it tends to explode at a less than optimal time in the normal four-stroke cycle. This is called knock, ping, or pre-ignition, and if left unaddressed, it can quickly destroy an engine.

That guy Mr. Ricardo, the British engineer from the ‘20s I just mentioned, was actually the first to observe knock while studying aircraft engines. You’ll be able to identify an engine “ping” as a metallic crunch noise when applying the throttle, a bit like aluminum foil being crinkled up.

Boost from a turbocharger or supercharger tends to exacerbate this issue, as cramming in a bunch of hot air can cause the fuel to ignite at the wrong time.

To alleviate this, some engines require you to run high-octane fuel, which is less prone to pre-ignition thanks to a higher combustion temperature – hence the high octane ratings of premium fuel.

How It Works

What Is A Variable Compression Ratio And Why Does It Matter?

In Infiniti’s new VC-T, the compression ratio can change to suit the given conditions. If you’re cruising down the highway and you wanna max out your mileage, the engine will automatically raise the piston position, thereby increasing the compression ratio and eking out more thermal efficiency. If it’s power you’re after, the engine will lower the piston position and decrease the compression ratio, which helps the engine tolerate more boost and make more power.

The piston height is made variable by an intricate connecting rod design that’s controlled by the engine control unit, or ECU. This electronic module will monitor what’s being asked of the engine (more mpg, or more power) and adjust in real-time accordingly.

This basically allows you to have the best of both worlds, with a decent punch when you need it, and decent fuel economy when you don’t. In fact, Infiniti claims that its 2.0-liter VC-Turbo engine can return approximately 27 percent more fuel when compared to a V-6 powertrain of equivalent power levels. The compression ratio for this engine would vary between 8:1 and 14:1, with the former ratio used for high boost and performance, and the latter ratio used for economy.

So How Exactly Does the VC-T Work Its Compression Magic?

Engineering Explained has a great video on this, and you can check it out below.

The basics breakdown like this –

The engine that Infiniti picked to pilot this tech is a 2.0-liter four-cylinder with port and direct fuel injection, electronic boost control, and variable timing.

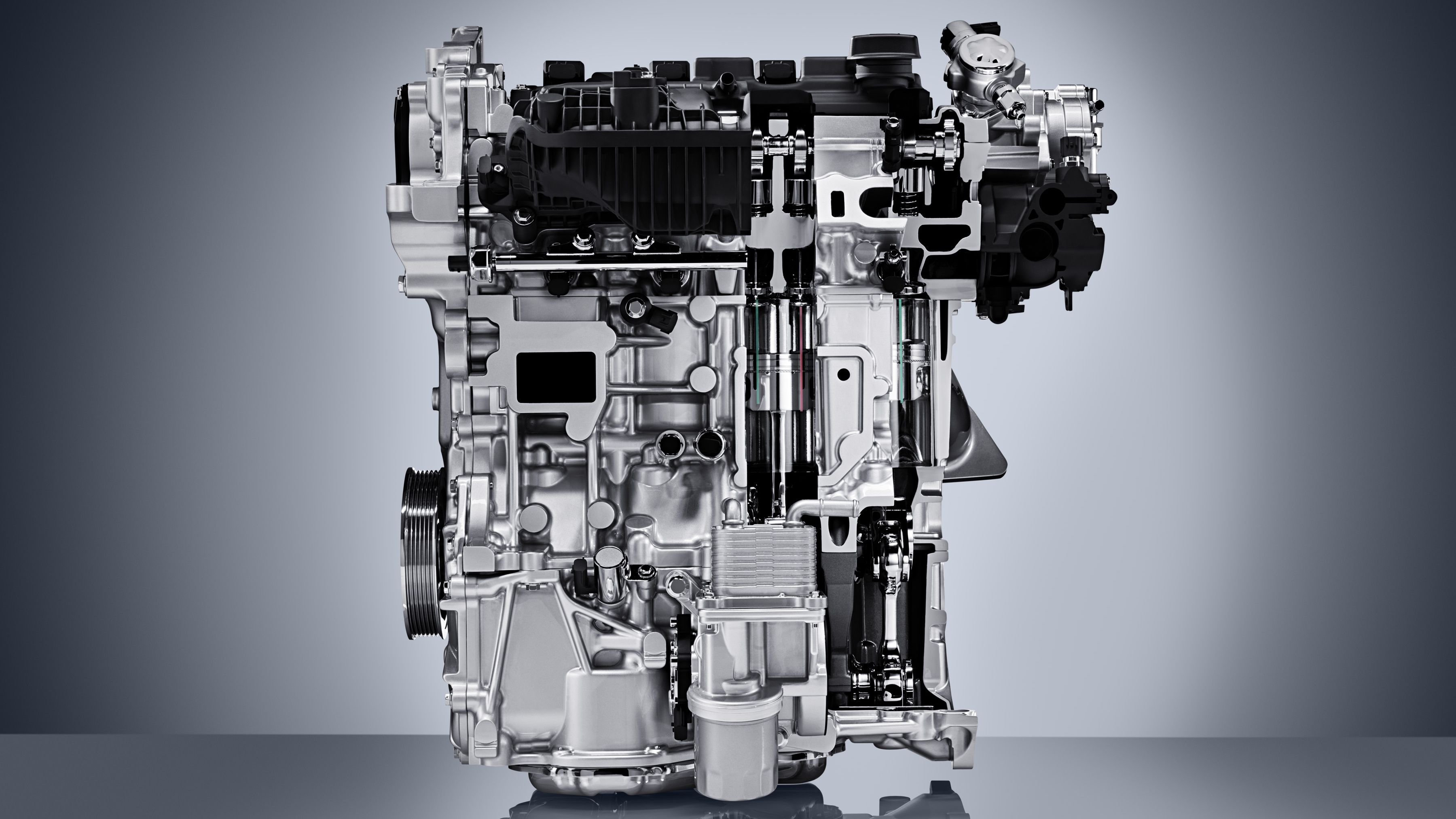

As you can see in the above image, the connecting rod is composed of multiple pieces, and is connected to a series of links and bearings.

When you’re cruising down the highway, the piston is raised (see image on the left), giving it a compression ratio of 14:1 and maxing efficiency. If you’re looking to pass a semi or merge, and you put your foot down for more power, the ECU will send a signal to the harmonic drive (1), which moves the actuator arm (2) and the control shaft (3). The control shaft then moves the angle of the multi-link (4), which is mounted around the crank shaft, thereby lowering the piston height. The result is a lower compression ratio (8:1, as seen in the image on the right), which allows for more boost, and thus, more power.

As previously stated, the advantage of this system is more power when you want it and more mpg when you don’t, given the compression ratio (piston height) can be changed on the fly to suit the given scenario.

Anther perk is more compact packaging, as the various links that make up the connecting rod take up far less space than an intricate hybrid system (for more efficiency) or additional cylinders (for more power). A smaller engine means more space in the cabin for people and things, as well as a smaller footprint on the road, making the car both more practical and easier to drive.

Finally, Road & Track points out that the engine “will be much smoother than any four-cylinder turbo thanks to the connecting rods remaining more upright throughout their stroke, with a torque curve very similar to what you’d see from a diesel.”

Questions Over Reliability

Of course, no technology is perfect, and while more power and more mpg seems like a winning combo, there are a few issues to pick through.

For one, the multi-link system Infiniti has proposed is much, much more complicated than a standard connecting rod, and with higher complexity comes additional opportunities for things to break. For example, what happens when one of the four pistons doesn’t adjust correctly while changing between compression ratios? Would the entire bottom end just grenade?

Our man Robert Moore raised this point back in September, saying, “There are a lot of extra parts moving in tandem with that crankshaft to help create the variable compression ratios. If this system is really going to see production, Infiniti better be damn sure that it can handle the rigors of everyday driving over the long term.”

A few months prior, after Infiniti made its big August reveal, Robert pointed out that many of the parts used in this system would need to be pretty thin to fit inside a normal four-banger block. And as anyone who’s rebuilt a performance engine will tell you, thinner metal means less strength, and less strength means less power. And that means this system would not be a good candidate for a high-performance application, such as a sports car or race car. Unfortunately, adrenaline junkies need not apply.

So Is It Worth It?

Depends on who you ask.

According to Road & Track, “Nissan also went for variable compression over electrified drivetrains to keep costs down, which might be an effective way to do some downsizing, but will hardly be clean enough for the environmental demands of the next decade.”

Basically, that means the VC-T was developed to add a little mpg cred without going full-bore into a hybrid system, essentially creating a stopgap until something else can be developed.

Variable compression isn’t the only groundbreaking ICE technology on the horizon. Last May, it was revealed Honda filed a patent for an engine with variable displacement. Essentially, the variable displacement engine would come equipped with a variety of cylinder sizes, and through carefully controlled cylinder deactivation tech, be able to combine specific cylinders for either more power (the bigger cylinders) or more efficiency (the smaller cylinders).

While this technology comes with its own issues (high levels of engine vibration would be one), it just goes to show how innovative automakers are becoming in the never-ending quest to improve the ICE.

Another interesting example of this is the “camless” engine under development by Koenigsegg and Freevalve, which basically replaces the camshaft with an actuator, offering more precise valve control and more efficient packaging. But of course, this too has its issues. You can check it out in detail in the following Engineering Explained video.

Similar Technology

Infiniti has every right to champion the VC-T as the way forward for internal combustion. While there are a few concerns with its application, I can’t help but be reminded of what the critics were saying when hybrid systems were hitting the mainstream. Back then, the extra complication of the battery packs and electric motors led many to believe hybrids were most likely gonna amount to no more than a flash in the pan novelty. Now, here we are in 2017, and clearly, hybrid technology isn’t going away. It’s a tech that’s becoming more effective with every cycle, and as a result, it’s gaining ever-greater acceptance.

Speaking more broadly, it’s advances like the VC-T and hybrids that lead me to believe we have a long time to go before we totally ditch the ICE as a means of transportation. EV proponents love to talk about the demise of gasoline, but if carmakers like Infiniti manage to bring technology like VC-T to market in a big way, don’t expect dino juice to go without a fight.