Touted to be the most critical safety feature on a motorcycle, the brake systems are quite obviously the lifesavers. Woking by converting kinetic energy into thermal energy (heat) by friction, the brakes of a motorcycle are some of the most abused mechanical components apart from the tires.

Manufacturers have come a long way from ‘putting a foot out’, to using metal discs and pads, to taking the help of some brilliant electronic wizardry, all to bring a heaving motorcycle and the rider to a halt in the least possible distance and in a safe controlled manner.

This guide elaborates on the various types of braking systems being engineered and equipped on motorcycles and some new technologies for future products.

Drum brakes:

The basic design of the drum brakes hasn’t changed much ever since it was first seen in the 20s’. They are a type of internal expanding brakes that consists of a brake drum and brake shoes. When the brakes are applied, a set of shoes or pads press outward against a rotating cylinder-shaped part called a brake drum.

Initially used for braking both the front and rear wheels, drum brakes have been mainly superseded by disc brakes or are used for rear-braking only on some models with low-capacity mills (80cc to 110cc) and the older generation of motorcycles.

Disc brakes:

A significant shift from drum brakes, disc brakes used calipers to squeeze pairs of pads against a disc or "rotor" to create friction. Unlike ones found on automobiles, motorcycle disc brakes are the ’floating’ type for optimum cooling and also avoids disc warping and reduce heat transfer to the wheel hub.

The discs are usually stainless steel, drilled, slotted, or wavy to disperse rainwater and assist in cooling. However, MotoGP machines and some of the high-performing sports motorcycles have Carbon brakes for a far greater braking force than conventional steel discs.

The Lambretta TV125 Series 3 was the first modern production motorcycle with a disc brake. The 1969 Honda CB750 put motorcycle disc brakes into the mass market, using a hydraulically operated single piston sliding caliper with a solid front disc.

1. Calipers:

The brake calipers are a pair of metal plates bonded with friction material - the brake pads. When you pull the brake lever, brake fluid creates pressure on pistons in the brake caliper, forcing the pads against the brake rotor and slowing your motorcycle.

It is usually a norm to situate the calipers behind the slider to reduce the angular momentum of the fork assembly. Traditionally, calipers are made in two halves, which are then bolted together but are less resilient to flex under load this way. Found on MotoGP and high performing machines, Monobloc calipers are those machined from a single piece of metal that are stronger but much more expensive to make.

a. Types of brake calipers:

3• Floating (or sliding) calipers:33}

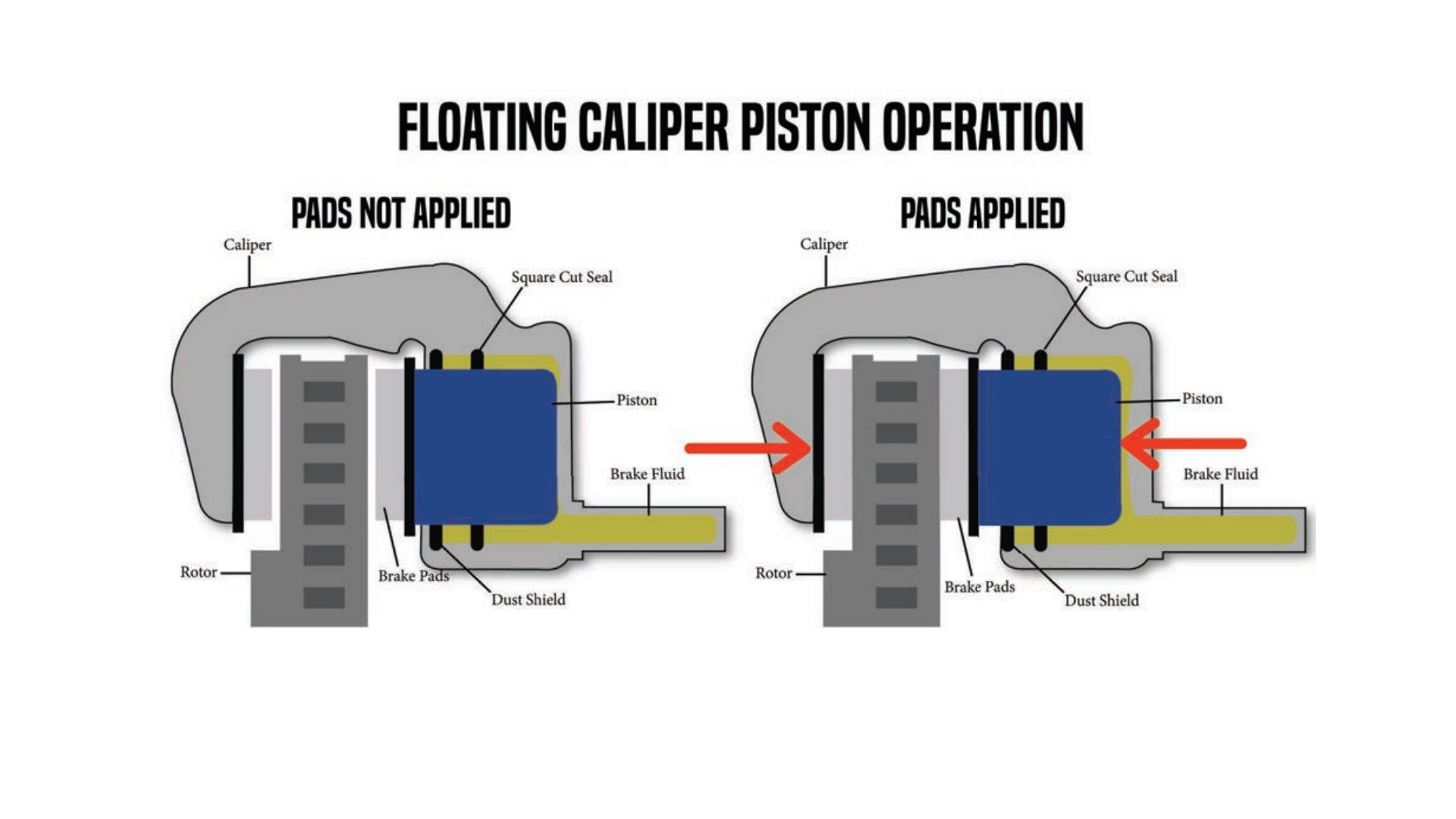

These are the first designs of calipers that have brake pistons that operate on one side only. They usually work with one or two pistons that push one pad onto one side of the disc and pull the other pad side into contact as well, creating friction from the brake pads on both sides of the rotor.

The major disadvantage of this type is if the caliper pins are not lubricated well, then the caliper won’t be able to slide correctly, the outboard pad won't be able to make contact with the rotor. This leaves the inboard pad to take over braking responsibilities. When this happens, you will see premature wear on the inboard pad.

3• Fixed caliper:33}

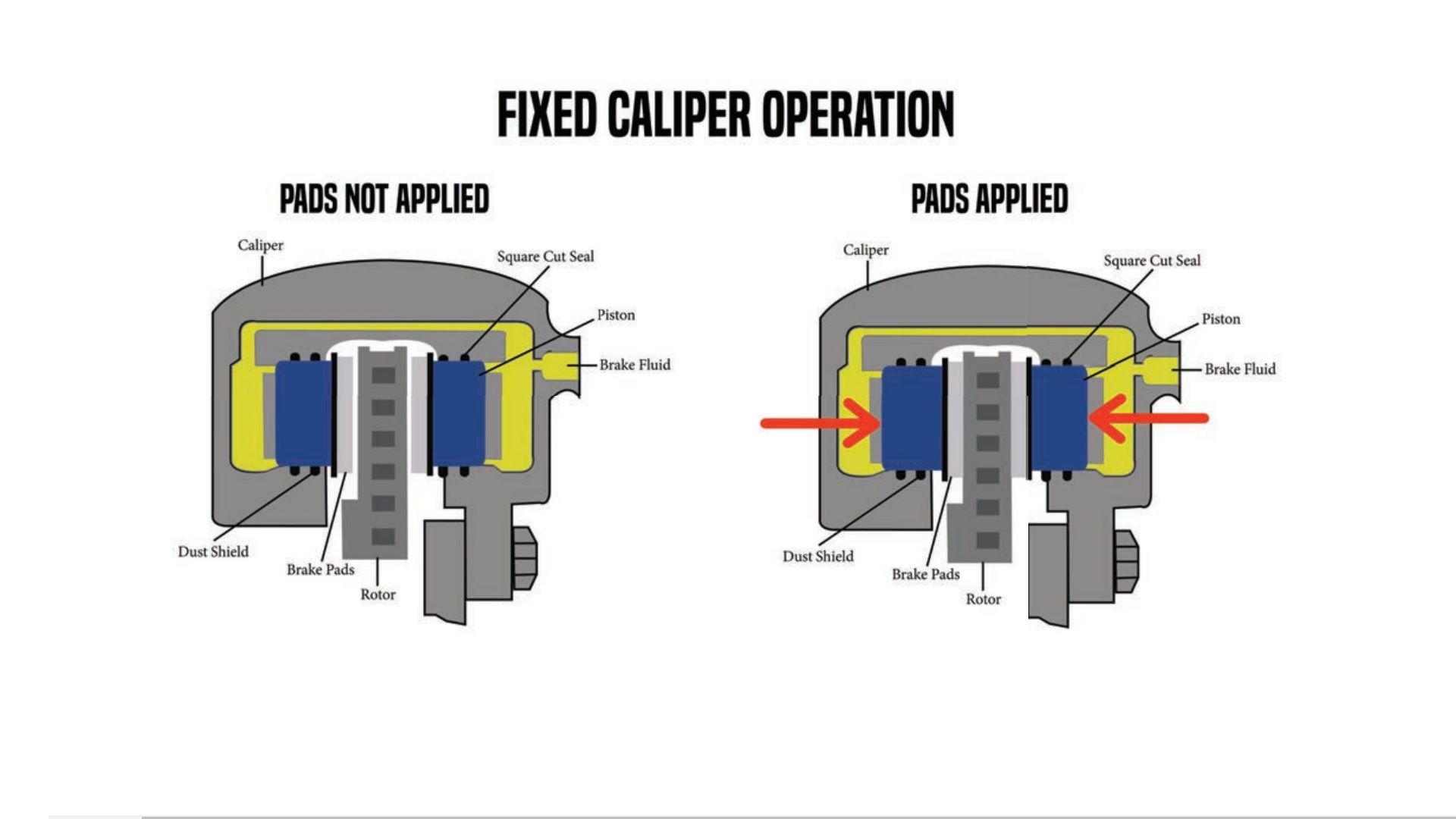

As the name suggests, these calipers are fixed into position to reduce flex. They usually have two, four, or even six pistons distributed on either side of the discs to improve the piston area significantly. When the brakes are applied, the pistons apply the brake pads on both sides against the rotor.

Fixed calipers are generally preferred for their performance, but are more expensive than the floating kind. The hydraulic brake fluid supplies equal pressure on both caliper sides for a mono brake pressure and wear.

b. Caliper mounting:

3• Axial-mounted calipers:33}

Axial-mounted calipers are held in place with bolts that are perpendicular to the discs, parallel to the axle. Mounted on the disc using sliding pins as on an axial setup, they are not suitable for bigger machines as they don’t have a good caliper-to-disc alignment.

Usually found on older motorcycles or ones on the bottom end of the spectrum, axially mounted calipers do not allow for changing the disc sizes without having to change the caliper itself completely.

3• Radial-mounted calipers: 33}

Radial calipers are more rigidly secured onto the fork stalk via bolts that run parallel to the discs. It provides for better caliper-to-disc alignment as it is centered over the disc using dowels rather than sliding pins. This improved alignment and rigidity can provide precise bite force, more stopping power, and improved feel under aggressive braking.

Replacing the discs with varying sizes is simple here compared to the axial-mounted calipers since the entire mounting bracket does not need to be replaced. Swapping out the caliper spacers is all you need to accommodate larger or smaller discs.

2. Brake pads:

The pads are the physical entity in the entire brake system that suffers the most. They are high friction material lined onto the caliper whose job is to convert your bike’s kinetic energy into heat in the form of abrasion. These pads have to do this particular action quietly and repeatedly, and without getting too hot.

Previously, brake pads (and linings) contained asbestos but was bad for the health when inhaled. Today, brake pads are made from a variety of high-tech materials that may include ceramics, Kevlar, and other plastics.

Types of brake pads:

3• Organic Brake Pads:33}

These pads are considered to be the safest ones that devoid any metal content or asbestos. Materials like rubber, glass, or even carbon and Kevlar are bound together into a heat-resistant binding resin. Organic pads are the softest and the most affordable options available that makes for a quieter, varied, and progressive feel and feedback to the rider.

These pads also go soft on rotor wear and produce less brake dust. The downside, however, is that they have a higher wear rate and are not as tolerant of high heat. They lose their friction coefficient at high temperatures, tending them useless.

3• Sintered Brake Pads:33}

Sintered pads are the most popular options available as they can handle a wide range of performance requirements. Made by bonding powdered metal (usually bronze) to the backing plate using extreme heat and pressure, it creates an excellent form a highly wear-resistant friction material.

This gives them a very high coefficient of friction that is maintained through the temperature range, making them ideal for aggressive use and racing. They perform well even in wet or muddy conditions and produce a good bite right away. They are, however, not very kind to the rotors and create a fair amount of dust. Sintered pads are also noisier than organics when brakes are applied, plus they are more expensive.

3• Semi-Sintered Brake Pads:33}

Semi-sintered pads are the best of both worlds composed of 20 to 40 percent or metallic substitutes. Combining long-life qualities of sintered linings with the low rotor wear and a progressive feel of organics, these pads are a good compromise for many riders and are a popular option for a variety of manufacturers.

3. Master Cylinder:

A cylinder or housing containing the brake fluid, the master cylinder converts mechanical force into hydraulic pressure through the brake lever acting on a piston that presses on a liquid. The size of the master cylinder, along with the force of the lever pull, determines the brake pressure applied on the rotor via the calipers and pads. In some cases, this pressure may exceed 150 psi.

4. Brake lines:

Originally made out of rubber, the brake line or hoses would lose its strength over time, and would require replacing it very often. They were also more susceptible to breaking during high pressures. To overcome these factors, manufacturers began using hoses that have a Teflon inner lining and was re-inforced by surrounding it with braided-nylon, Kevlar, or stainless-steel layer.

5. Brake fluids:

The hydraulic fluid that is all responsible for creating pressure between the rotor and the caliper, the brake fluid transfers the lever force into pressure, and eventually amplifies the braking power. To do this effectively, the fluid must have properties like non-compressibility, low viscosity, high boiling-point, non-corrosive, and excellent lubricity for master-cylinder and caliper pistons seals.

They have to meet specific requirements as defined by various standards set by international, national, or local organizations or government agencies like ISO or like the ones classified by the US Department of Transportation (DOT). Available in DOT 3, 4, 5, and 5.1, they must be colorless or amber, except for DOT 5, which must be purple since it is a silicone-based fluid while the rest are glycol-based. DOT 5 brake fluid is not compatible with anti-lock braking systems.

Anti-lock braking system (ABS):

An anti-lock braking system or anti-skid braking system (ABS) is a safety system that allows the wheels on a motorcycle to maintain tractive contact with the road surface and preventing the wheels from locking up (ceasing rotation) that results in avoiding uncontrolled skidding.

With ABS, the rider is sure to stop with a much-controlled state, but can also maintain the right direction of travel with an additional piece of tech called “cornering-ABS”. The module takes inputs from sensors for the lean angle, pitch axis, roll rate, accelerometers, and much more. This data is then analyzed at the rate of one hundred times a second to give the rider the best braking performance at any riding situation without having him change directions.

The video takes three different scenarios to show the handling of motorcycles with and without ABS in place. Cornering-ABS comes on select KTM->ke1954 models.

Alternative New Motorcycle Braking Systems

1. Regenerative Braking:

Also called motor braking, all of the electric motorcycles come with energy regeneration where power is sent back to the battery by recuperating decelerating heat energy during braking to electric. The electric motor acts as a generator where the heat is immediately dissipated in resistors during deceleration. In addition to improving the overall efficiency of the vehicle, regeneration can significantly extend the life of the braking system as its parts do not wear as quickly.

2. Kinetic Energy Recovery System (KERS):

Kinetic Energy Recovery System (KERS) is also another form of regenerative braking where the recovered energy is stored in a reservoir (for example, a flywheel or high voltage batteries) for later use under acceleration. KTM first experimented with this system during the 2008 season-ending 125cc Valencian Grand Prix. The Lit C-1 electric motorcycle will also use a KERS as a regenerative braking system.

3. Emergency Autonomous Braking System:

A system being developed by Harley-Davidson, this will make use of multiple sensors including cameras, RADAR or LIDAR, to study the surroundings as well as the alertness of the rider before it intervenes to activate the braking systems autonomously.

If it senses the rider not being prepared for emergency braking, the system will send out various warning indicators, both visual and audible, or might also set the handlebar and the seat with haptic vibrations. The system will also try to apply pulsating braking and closes the throttle in half, just enough to catch the rider’s attention and waits for a brief period of time before autonomously applying the brakes and slowing down the vehicle.

4. Parachutes:

Drag-racing motorcycles can reach speeds of up to 250 mph in a quarter of a mile. To get these monsters from such high speeds to a stop, additional re-enforcements like parachutes come in handy apart from the carbon disc brake setup they carry.

Useful tips for getting the most out of your braking system:

1. Always rely more on the front brake than the rear one with the foot. In most of the cases, it will produce between 70 and 90 percent of the motorcycle´s braking power.

2. Learn how to come to a controlled stop. Ease off the throttle, change to a lower gear, and use both the front and the rear brakes equally.

3. Aggressive acceleration and deceleration will hamper not only your brakes but also other issues like tires and economy.

4. Replenish the brake fluid only with the manufacturer’s recommended rating.

5. Conduct a proper brake line bleeding to remove any air from the system.

6. Make sure the brake fluid is DOT rated.

7. Replace brake pads before it reaches 2mm in thickness.

8. Do not allow dirt or dust to sit on the rotors. Always keep them clean.

Here’s a link to a video to guide you through changing brake pads: