It has been over a month that the world witnessed the end of the 2017 MotoGP championship. But for many like me, excitement levels are even higher now with the teams busy putting the 2018 MotoGP bikes through their paces and testing their readiness at the Winter Tests. It sure does not come cheap. Teams spend close to $100 million a year.

Manufacturers put in all their resources and money into running the best of their machines on the world stage and claim for the ultimate crown. Pool it with the talent and the knack of precision shown by riders, this is no ordinary show. All are vying for the glory of unadulterated use of power and the pride of being at the top of their game.

To be there, it is only made possible by the crazily engineered equipment and mechanicals that take the riders well over 210 mph and help keep them planted on the asphalt at those blazing speeds. Be it the 270 hp powertrain or the carbon brake units, they are top-notch magical devices that we peasants can only dream of having on our street bikes.

Here are five of the most critical units MotoGP has provided insights for. Watch these mechanical feats on the $2 million GP bikes working and be awed.

1. MotoGP engines

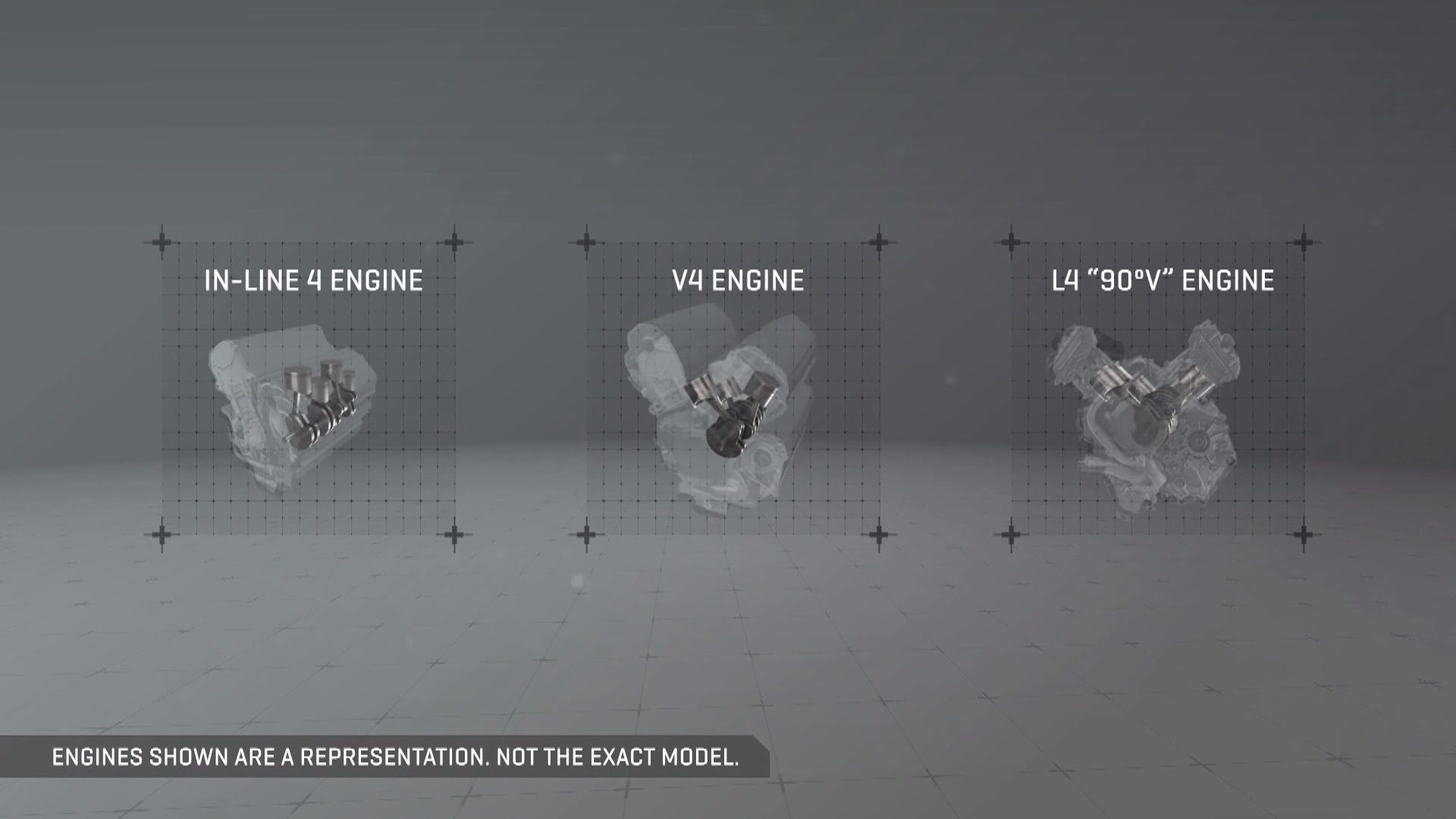

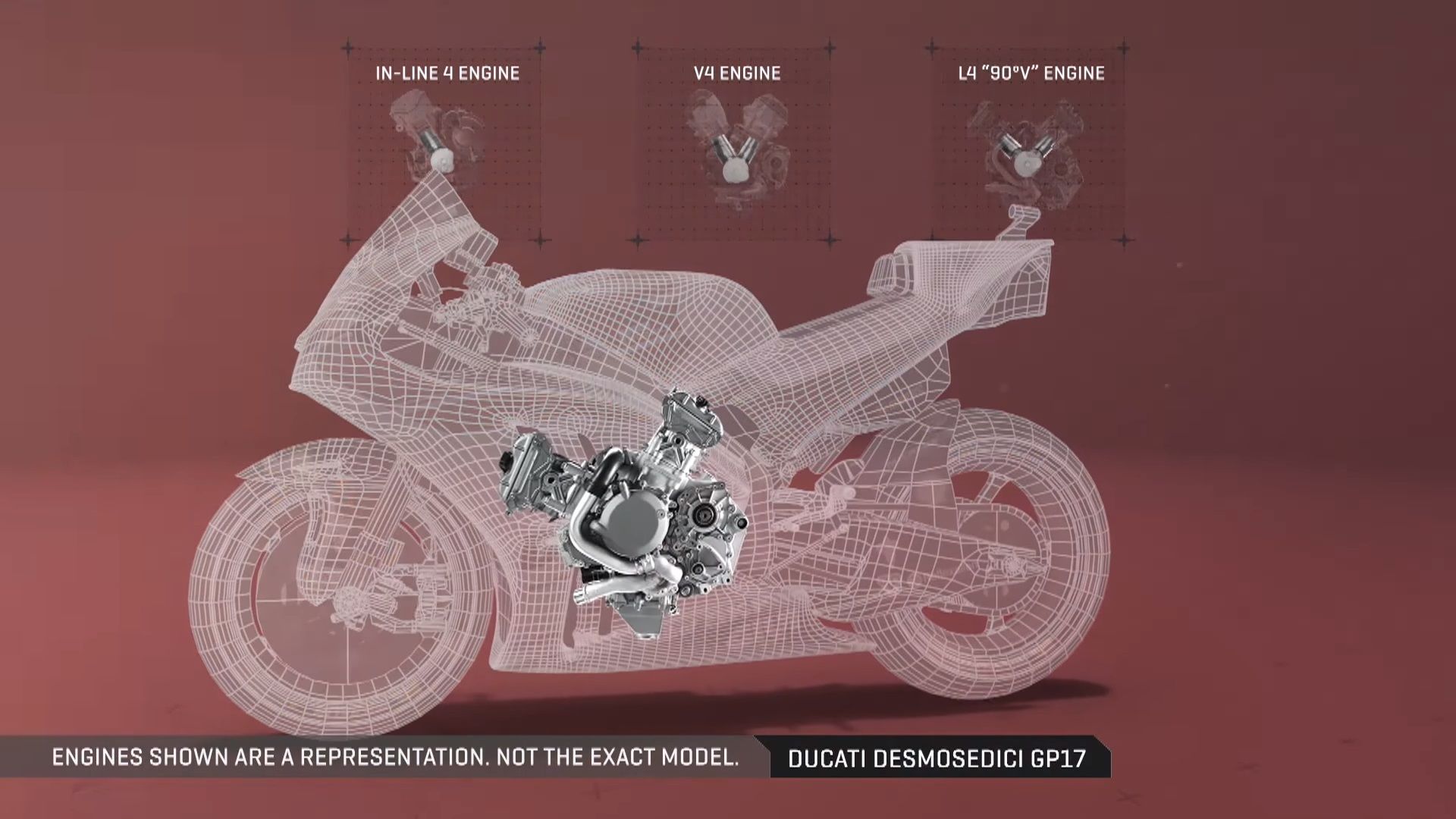

At the beginning of the new MotoGP era in 2002, 500 cc two-stroke or 990 cc four-stroke bikes were specified to race. By 2012, after many alterations, the MotoGP class would switch to the 1,000 cc motor with maximum four cylinders having 81mm bore. The engines are the most expensive part of these bikes costing around $220,000.

Each rider was allowed to use a total of seven engines per season (18 races), and each of them now carries a Magnetti Marelli ECU and software package with around 30-40 sensors that allow the teams to tweak their performance levels to gain any possible advantages with their engine performances.

Max speed can go a little over 215 mph and power pegs at 270 hp. There are things like the fly-by-wire, pneumatic valve timing, and electronic gearbox with an auto-blipper feature that assists in quick downshifts. The idea always is to trickle these techs to road bikes eventually, and that is how we get the R1-Ms’, GSXR-1000Rs’, RSV4s’, RC213V-S and the Desmosedici RR’s.

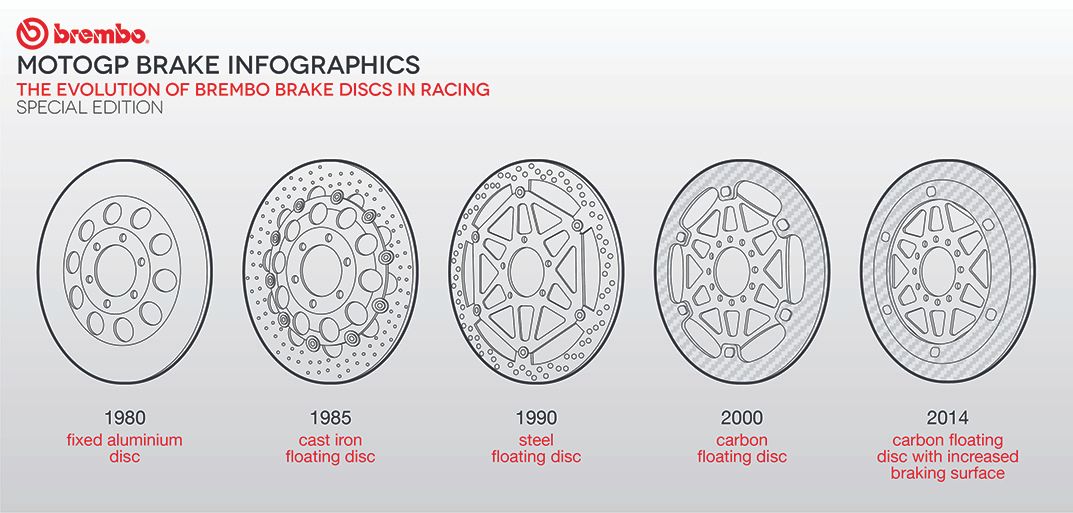

2. MotoGP Carbon brakes

Bringing a MotoGP bike from 180 mph to 60 mph in under 5 seconds is a feat almost impossible to achieve on any street bike running on traditional steel discs. That is a job left to the top-spec carbon-ceramic brakes on these GP bikes that applies almost 3 tonnes of pressure on the pads to slow the bikes down at 4Gs’.

Back in the days, aluminum, cast-iron, and steel rotors were made use of, until in the year 2000, teams opted for carbon ones for their efficient operation capabilities at high-temperatures. The brake pads are also carbon placed in aluminum caliper blocks. Of course, you get steel braided wires.

For carbon discs to perform at their best, they need to get up to temperatures that reach 600 degrees. Carbon doesn't suffer from the friction torque like in steel and also does not stretch the brake levers throughout the race. However, they get replaced with steel rotors in rainy conditions.

Nonetheless, Brembo, the sole brakes supplier to MotoGP has been improving the brake rotors and uses more exquisite materials with carbon to make them work even in rainy conditions. A set of carbon discs, carbon pads, and monoblock aluminum calipers would run you between $10,000 and $15,000.

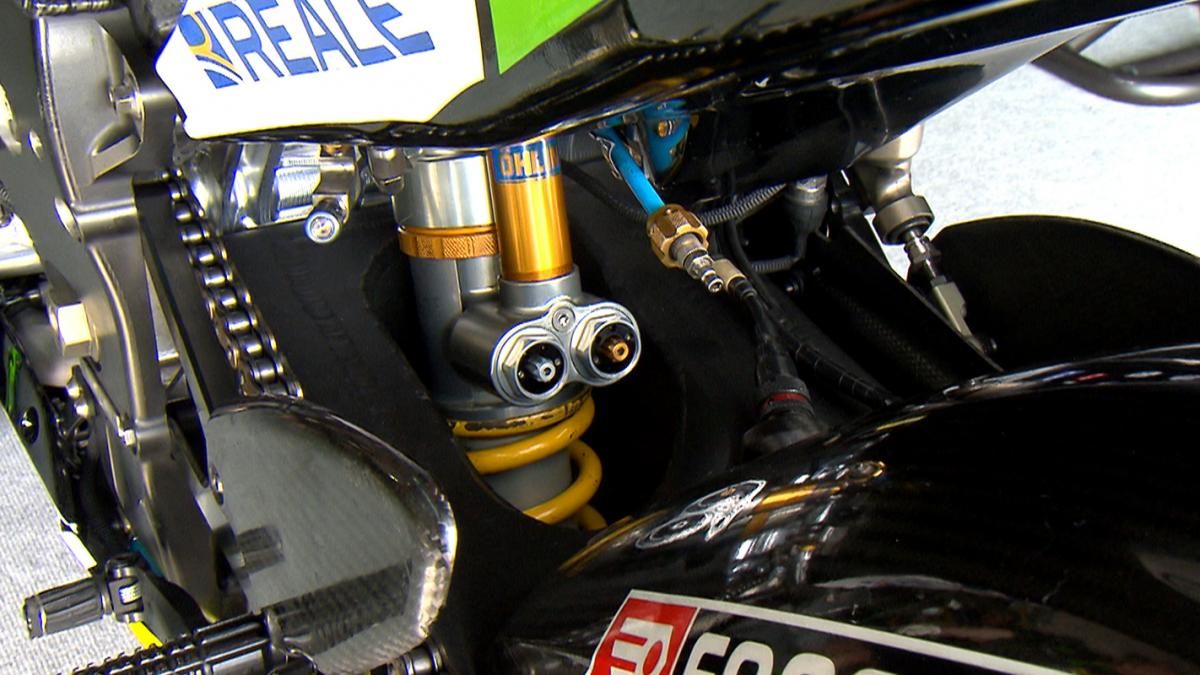

3. MotoGP Suspension

Just like how Brembo have dominated in the braking units, the Swedish manufacturer Ohlins have a monopoly over the MotoGP bike’s suspension setups apart for the KTM’s who are using WP units. Called the FGR300, the front forks gets fined tuned and custom adjusted for every rider. And they cost up to $100,000.

They get interchangeable springs, hydraulic damping, color-coded adjustment knobs for compression and rebound. They also feature a click setting function for the spring preload. Both rebound valve and compression valves can be adjusted to rider settings too.

At the rear, Ohlins TTX 36 GP spring strut on individually developed swingarm does the business. The suspension also decides tire wear and grip levels available for the riders. Providing the perfect feedback is the job of the folks at Ohlins to either soften or harden the rates depending on the rider’s weight.

4. MotoGP Tires

The tires are the ones that make the machine have contact with the ground. So the compound used on them can have a huge impact on how the machine interacts with the track. For the longest time in MotoGP, Bridgestone, Michelin, and Dunlop gave rubber to the bikes.

In general, race tires are made with stickier, softer compounds to provide the grip needed to keep the bikes from sliding off the track in the corners. These tires, which can withstand higher temperatures have a drastically shorter lifespan.

Currently, Michelin is the official supplier for tires and provide 10 front tires and 12 rear tires for a bike per race weekend. They can choose between five different tire compounds (extra soft, soft, medium and hard) and a wet compound tire.

Since these tires are never sold, the cost of each tire is unknown. Michelin charges the teams with the cost of tires, the technicians, mounting, balancing, monitoring, and transporting the tires to and from the venue. Additionally, every race has a chemist and engineers in attendance to gather information.

Rumours around a few internet sources claim that teams spend around $ 4 million per calendar year just for tires.

5. MotoGP Electronics

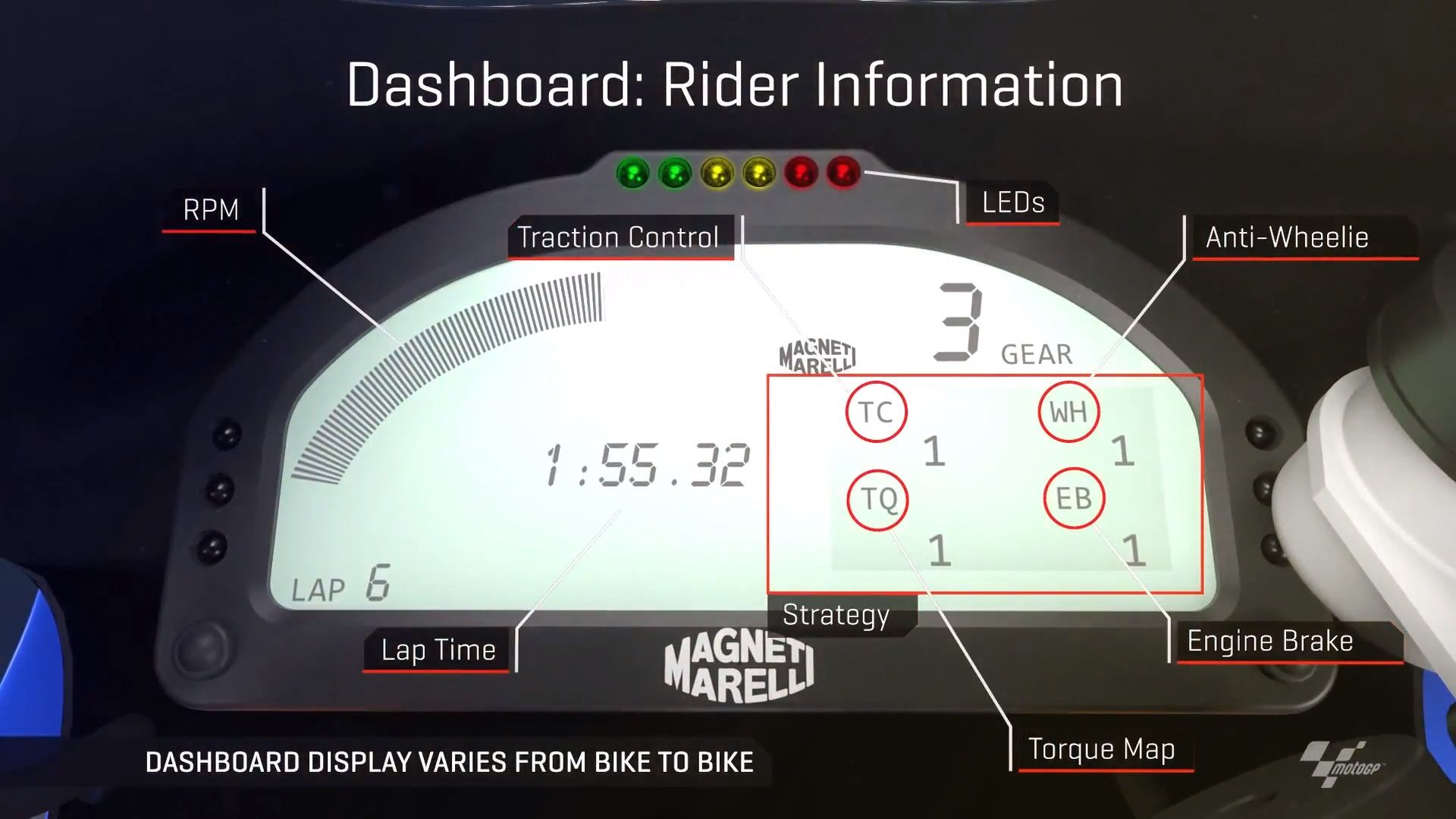

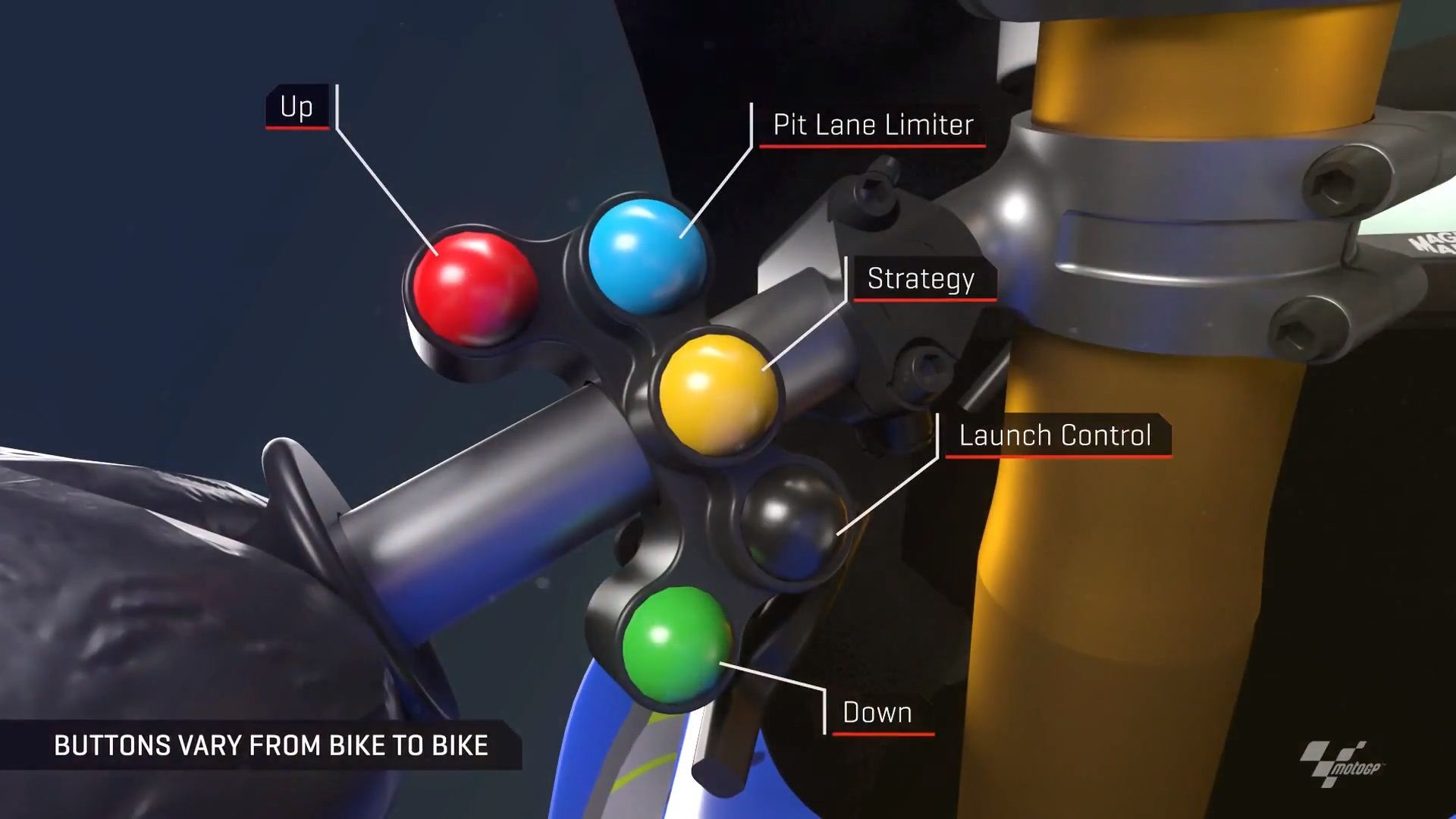

Accessible via the 2D dashboard, the rider has access to a myriad of options including traction control, torque map, engine brake, wheelie control and much more. All these settings can be optimised by the rider live in the race using colored buttons on the handlebar.

The motorcycles also have from 30 to 40 sensors that gather data, such as suspension travel, brake and exhaust temperature and steering angle. While the sensors will not cost less than $1,000 each, the 2D dash will be around $2,500 itself. And the wiring harnesses, that will be anywhere between $8,000 - $12,000.

The dashboard display and the switch buttons vary from bike to bike depending on rider preferences. Magnetti Marelli ECU and software package feeds the information onto the dash. There is also a button to limit the bike to 37 mph when the rider enters the pit lane.